I have been planning for some time to set up a mini-generator on a heat stream, the device is nothing special, if you are familiar with how a heat pump works, pumping heat from a low level to a higher one, this device would use the heat stream in the opposite direction, similar to a steam engine, but here the system will be closed. I will use a scroll car compressor , which I have already removed the non-return valve and tried running on compressed air , it works fine. The next elements will be two heat exchangers, one heated with water in the 80-60C regime, the other cooled with water 25-30C (underfloor heating). The biggest problem is the hermetically sealed mini-pump that would pump the liquid phase of the refrigerant (which is likely to be propane or R134a) from the cold exchanger to the hot…

We have already raised this topic somewhere in our posts , but it has not developed much. Has anyone tried to do something similar?

I think what you are describing is called an Organic Rankine Cycle (ORC) Bottoming Cycle in the industry. Phase change Rankine cycle with a refrigerant rather than water to take advantage of lower temperature heat sources.

Totally doable, no real technical problems that I know of.

Only thing I’d point out is that Carnot tells us these systems will always be very low thermal efficiency. The low delta T means that even though you have a large amount of low grade heat, the amount of energy you can extract from it is quite low.

And this affects the economics of it all because you need a relatively large plant size and get a relatively small amount of power.

Chuck,

How do they keep frost/ice from building up on the cold side? I studied Stirling cycle machines. I understand they make great cryo-coolers.

Rindert

Just for fun or you expect some usefull power output? Why these heat resources?

Rindert, I don’t know much about the thermodynamics of ORC systems, but it looks like the entire cycle is above 273k (32F).

https://sites.google.com/site/bishanshancheerup/research/orc

I imagine it’s like the AC evaporator in your car… the heat flowing through it generally prevents it from icing up.

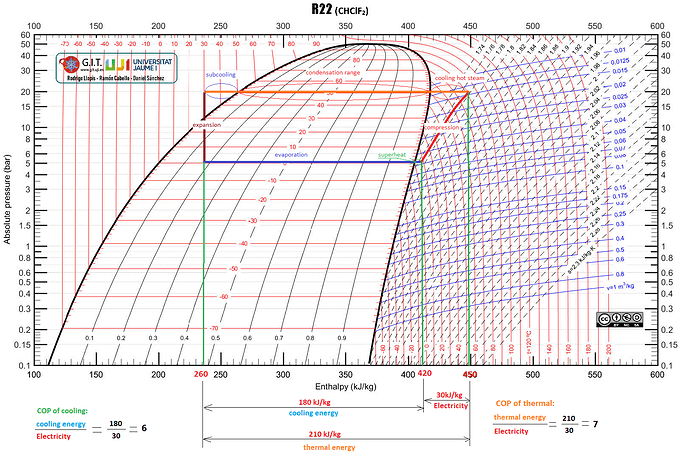

In the diagram I tried to draw a theoretical process of processes, … actually similar to a heat pump, but only in the opposite direction, otherwise the theoretical efficiency (12%) is not bad, but we have to subtract a part of this for pumping liquid phase pump refrigerant and friction losses on the compressor will probably be less than 10% but this is also good. If I take the total heat of 10kW, which I use for low-temperature heating, this should be enough to produce 1kW of electric power. Friends, what do you think … Jo would probably say I’m fantasizing a bit

I drew the last diagram for the heat pump process

I would advice you to try some waste heat at the hot side of your system.

Tone,

I will give you my standard answer: Give it a chance, you will never know for sure until you try it out in your own “Real World”.

Besides, you will waste that much time thinking about it all the time… What If…

Besides, you will waste that much time thinking about it all the time… What If…

Dal vam bom svoj standardni odgovor: dajte priložnost, nikoli ne boste vedeli zagotovo, dokler ne preizkusite v svojem “resničnem svetu”. :sončna očala:  Poleg tega boš zapravil toliko časa, da boš ves čas razmišljal o tem … Kaj če …

Poleg tega boš zapravil toliko časa, da boš ves čas razmišljal o tem … Kaj če …

Kamil, I agree, part of the high temperature from the flue gases would raise the efficiency, but the Teflon seal on the screw can withstand temperatures up to 100 ° C.

Come on guys!!! Now I have to learn even more stuff to cloud my brain with and keep me from concentrating on my main project.

You and me both. Lol

Bob

Tom, the brain has to be busy, otherwise they start studying various nonsense, some result in divorce, some are overwhelmed by alcohol or drugs, some deal with the borders between a neighbor or a driveway, …

Tone,

I’ve been huffing too much woodgas to make those diagrams make sense. I have no doubt you could make that thing work, but I do doubt the floor heating return-loop flow is enough to cool off 9 kW of “waste heat”. Windows wide open may help  A separate loop from the bottom of the storage tank would probably be necessary.

A separate loop from the bottom of the storage tank would probably be necessary.

The beauty of this system is it could run 24/7 and not be dependent on occational flue heat.

Let’s make it the other way. What purpose is the power generated for? General home usage? Battery charging? Feed some specific appliance, like refrigerator or water pump?

Another question - what is your heat source heating this hot water? How it is connected to the floor heating, which constitute the cooler in your cycle?

Hello Kamil, for the production of hot water I use only wood, somewhere on the forum I have already described the boiler room, … This was initially a hobby attempt to test the theory, using a 12V car alternator as a generator, but if it turns out to be good, this will be a very interesting device in my opinion, as in summer it would be possible to heat water with solar collectors, … let’s say an alternative to photovoltaic panels. However, as I wrote, I can’t find a suitable mini pump,., This is how an air compressor works, good torque already at 6 bar, … https://youtu.be/5MbnkPLqlhA

Sounds like smart plan. I have two points.

I suppose you could hardly depend on floor heating as a cooler in summer. If you need 9 kW in summer, I could hardly imagine how much you need in hard winter.

If you want to use propane or R134a with hot side temp close to 80 °C, you have to count with much higher pressure, 30 bar plus. Same thing at the cold side, both refrigerants condense in your temperature range above 10 bar.

Kamil, if you look at the first diagram, there is a pressure scale R134a on the right, 80 * C water heats up and gasifies the refrigerant, vapors do reach 80 C, but the transition from liquid to gas is lower and this process determines the pressure - red top line. In summer, it would dissipate waste heat into the surroundings, …

Right you are, @Tone. My fault to ignore your diagrams and count with saturated vapor. Acording to the first one, your operating pressure will be around 18 bar, am I right?

Heat exchangers are never 100% efficient, so you could hardly get equal temperature of input and output. Unless you have enormous heat exchanger area or minuscule mass flow.

If your cold side is between 35 and 30 degrees, then you have to shift bottom blue line up, to proper temperature. This will again harm the efficiency. In winter, when all waste heat would end up in floor, no problem. But in summer, the investment in collector will be in doubt.

To long ago for this old man. But now you have my attention. Can you put any power numbers at it?