those engines will not go much above 4k RPM…as I work on them daily. they do NOT have a pressure lubrication system and the one that is used is designed to keep the crank and rod lubricated at 3600 rpm…most are governed down to 3350…they are poorly internally balanced and the internal tolerances are not close enough to allow that kind of rpm for any length of time

For the price of an RPM-matching prop, I can most likely get at least 5 replacement engines. And this project should be budget friendly, so with that in mind, trying to increase engine RPM isn’t that odd IMO. Also, the donor outboard engine was a 70-80’s creation. Which would probably limit my prop-buying-options even further. I did consider it.  (do have an scrap 5 hp volvo penta outboard engine, which would rev only to 4.800 rpm, but I’d most likely have to use that lower unit instead of the current one. And I’d probably need to increase hp output of this lawnmower engine)

(do have an scrap 5 hp volvo penta outboard engine, which would rev only to 4.800 rpm, but I’d most likely have to use that lower unit instead of the current one. And I’d probably need to increase hp output of this lawnmower engine)

I had been thinking ahead. I had angled the engine in such a way, that the spark plug/electronics and fuel system, was aimed towards the back. So less chances of water spray becoming an issue. (and the stock exhaust was aiming to the back asswell)

@ your woodgas content comment… Lawnmower engine on a surfboard is crazy enough for now IMO. Don’t need to mention I’m adding a towing bar, so I might be able to tow some kind of tiny barge. And that it’s part of the reason for wanting a 4-stroke lawnmower engine. (adding oil systems to one of my small outboard engines, is beyond my skillset/budget) And yes, I know it will cripple the HP, and especially top speed. But my initial goal still is: relaxing cruising speeds. And as you can see, I do read all comments. (also your previous ones) No need to hate.

Thnx for your insights. I’ll be ordering one of those “wrap this wire around the sparkplugwire” RPM gauges tonight. Chances are I will tip over at one point, and brick an engine that way. But I do intend to have some fun and not just blow up engines within 15 minutes of runtime.

if you go to the Zena welder site…they have a 2cycle 6.5 or 7hp engine they run a backpack welder on…I believe it is around 7500 to 8000 RPM…might consider looking into what they have found…

I guess that product is no longer available through Zena welders…sorry…How about a lawnboy 2 cycle engine …they are about 6.5 hp…and rev to about 6000 rpm?

There are a few issues with your suggestions.

1: They aren’t 4-stroke.

2: Never heard of them/probably very hard to find in my area/country (Netherlands)

3: If I’d tip the board, I might have bricked the engine, and thus have lost decent moneys.

4: Lower unit I’m using, had a 3.5 hp engine. Want to remain close to that power figure.

If I wasn’t worried about the cost, and if I didn’t care about 2 or 4-stroke, I could use one of my smaller 5 hp outboard engines. (got a 5 hp Volvo Penta, and a 5 hp Yamaha. Both 2-stroke, both in good working order, both air-cooled, both “could work” as an surfboard powerplant but they are also both worth a few hundred euros. And I want to keep this really low budget/just for fun)

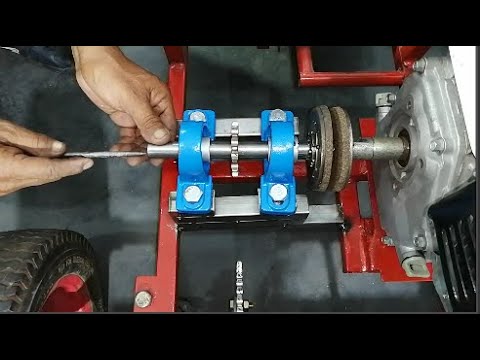

how about instead of direct drive fabricate up an adaptor to run either pulleys and belt or chain and sprocket…a 3 inch pulley/sprocket on engine at 3000 rpm driving a 2 inch pulley on out drive would give you about 4500 a 3.5 inch pulley /sprocket will give 5250 rpm

I already tried giving that advice he doesn’t want to put any more money into it.

Jahee,

I don’t know your engine specifically, but many small engines have maximum torque around 22-2300 rpm. I would try to use the engine where it has most torque, because better engine response and more fun. I would make a belt drive speed increaser. Sounds funny to say that. LOL I would try to use ideas from kids building go-karts.

Rindert

-Belt drive system would get wet.

-Limited tools, so it would be hard to align sprocket/chain set-up.

-Very limited funds, so I kinda can’t pour money in this junk-but-probably-fun project.

-Surfboard, so very little space.

-Surfboard, so it needs to be very “lightweight”.

-Infront of this colar I made under the engine, is the (stock) gearselector. Will still need to extend it. To keep it functional, it needs to be there. So there is no way I can mount a sprocket system infront of driveshaft.

-Rudder needs to be close to the prop, and I’ll be using chain/sprocket/steel cable steering. So there is no space behind the driveshaft for any reduction systems.

-If I’d raised the engine, I might have more room for a reduction system. However, it would make this contraption much more top-heavy, and that’s an issue.

If slow cruising speeds is all I’m going to be able to do, it’s fine. Only way I saw to increase top speed, was to increase engine RPM. Turns out, these kinds of engines just can’t handle higher (4k++) speeds. I’ll accept that as a fact, and will try to keep the max RPM to around 4k.

You NEED a safety cutoff so the prop stops, if your hand isn’t on the throttle. You fall off there is a good chance, that thing isn’t going straight, and it is going to head rights towards you.

I wouldn’t even put 3hp on a canoe, muchless on a surfboard.

If I WAS going to do it, I would use an electric trolling motor. They can be had for cheap with broken handles and crap. And you really just want the sealed motor. Here is a commercial product:

But here is a product you just attach to the board add batteries and call it a day for inspiration.

Dc24v Or Dc12v New Electric Surfboard Fin-sup Power Efin Trolling Motor Electric Sup Fin And Stand Up Paddle Board Electric Fin - Boat Accessories - AliExpress?

Hi Jahee, I would do the following in your place: - I would try to grind the cylinder head to increase the compression ratio, which has a beneficial effect on combustion speed at higher speeds - I would replace the exhaust muffler with a more fluid one, … a perfected tube with a muffler lining -I would install a more fluid air filter

My contraption will be just like a regular outboard engine. Dead-mans switch, and that’s it. Adding a system where the prop instantly goes to neutral when I’m not on the board, sounds like something really complex, which might only work in 50% of the cases of me falling off.

Safety improvements I will have over a regular outboard engine: throttle will be pulled back to idle speeds when I’m not touching the throttle. (I’ve had outboard engines where I could set the throttle to a certain RPM, and then just not having to touch the engine) And I will make some kind of a cage around the prop. (which is kinda rare to see in my area)

As for going electric: I’m not a wizard, I don’t do magic, don’t want to work with electricity. I also like the sounds/experience of petrol burning in an engine. But whats more relatable for most is… Just add more fuel, and you’re good to go again. Action radius depends on how much fuel you can take with you, and if you can make regular stops @ a fuel station. Having to carry spare batteries, sounds less optimal and costly. (otherwise, great suggestion)

Thnx for the suggestion! I remember seeing someone who used a belt sander to grind the cylinder head, to increase compression. Does look scary, because you kinda can’t fix it with the same tools, if things go south.

Will replace the stock exhaust, for some kind of straight-pipe exhaust system, and I will remove the air filter. Once I’ve finished this thing, and know how it operates, I might make an new air intake tube, where there are even less chances of catching random water spray. (don’t think it’s an issue, might be an issue)

Think it was those people from carsandcameras on Youtube, where they used a belt sander to shave the cylinder head. They also mentioned that some people would use a flattened piece of a soda can as gasket. However, I for sure won’t use this second suggestion. Sounds WAY too iffy to me.

Man thats a scary looking thing your building.

And I would know I like scary things that go too fast.

I have a bad feeling your going to flip it over and it will ingest a cup full of water and that will be the end of your experiment.

Jesus man!

Be careful…

I considered to offer you some speed tricks for that GVX.

But I just don’t think its a good idea so I decline to say anything more than.

JUST BE CAREFUL.

That works but draw fill its faster and your have more control.

Ya… No…

Copper sheets can be had pretty cheap on ebay.

Slightly necro-posting here. While keeping an eye out for lawnboy lawnmowers (VERY rare here), I finally managed to buy a broken/non running lawn boy 8440. Got it to kinda-ish run. But it’s having an issue, and I don’t know what’s going on here. Had a 2-stroke outboard engine with a broken crankshaft seal once, and it didn’t run nearly as good as this one. Any suggestions? (paid 25 euro’s for it, including personal delivery)

It’s surging. Probably the carburetor. I don’t know Lawnboy engines but if they’re Reed Valve it could be that too.