hi henry what is tortified wood pellets and how are they made differently than normal wood pellets people claim all the time to have something better but when you check they are normally all the same . just a processing difference???

Torrefaction is a thermochemical treatment of biomass at 200 to 320 °C (392 to 608ºF). It is carried out under atmospheric pressure and in the absence of oxygen, i.e. with no air. During the torrefaction process, the water contained in the biomass as well as superfluous volatiles are released, and the biopolymers (cellulose, hemicellulose and lignin) partly decompose, giving off various types of volatiles.[3] The final product is the remaining solid, dry, blackened material[4] that is referred to as torrefied biomass or bio-coal .

During the process, the biomass typically loses 20% of its mass (bone dry basis) and 10% of its heating value, with no appreciable change in volume. This energy (the volatiles) can be used as a heating fuel for the torrefaction process. After the biomass is torrefied it can be densified, usually into briquettes or pellets using conventional densification equipment, to increase its mass and energy density and to improve its hydrophobic properties. The final product may repel water and thus can be stored in moist air or rain without appreciable change in moisture content or heating value, unlike the original biomass.

The history of torrefaction dates to the beginning of the 19th century, and gasifiers were used on a large scale during the Second World War.[5]

Everything is white here for 4 months of the year there is nothing black here. Ive done all this, we get two months a year where sun bathing is effective. 1 yard chips will take up a big space you would need a parking lot an its not practical.

ya every thing is white here to. so the pellets have less heating value as it is turned half way to charcoal. It looks like another goverment screw up to me . 10 per cent doesnt sound like much but at 10 or 20 tons per hour that is a lot of fuel burned to make up the lose. we are suppose to be trying to stop global worming not make it worse… just shaking my head… treudo was and alway will be a screw up for allowing ihis

lets keep trudeau out of this since it was before he was in office…

Hey Bryan. From what I glean from the video the internal vessel is a hot water tank. So the unit dimensions are random. It certainly does a good job of cooling the char below the combustion point, but it might work equally well if shorter, how much would be a matter of R&D. If it was somewhat shorter it would be more amenable to indoor use.

I figure if the combustion area was enclosed and provided with some sort of heat exchanger it could serve as an indoor heater or boiler stove. The tricky part would be to provide and regulate auto feed and auto char removal. But with a bit of thinking that should be achievable with sensors and arduino or similar.

This are the misleading parts/words , unintended , but it only depends in what way you look into the calculation.

If you buy 1 kg of torrefied wood, you have a higher heating value per Kg then if you would have just raw wood.

It is similar as the first stages in a raw wood gasifier, the drying and condensate what comes out somewhere down the line… The losses in the gasifier from that are higher then from a better controlled system before the fuel gets into a gasifier.

Try to picture yourself a gasifier that does not produce condensates nor tar and no char… only gas and ashes…

What does it takes ?

Fuel prep and balance…

If you run that sweet charcoal maker as depicted in that youtube clip a bit faster, then the outcome is more or less the torrefied wood.

retort charcoaling between 300 and 400ºC has also this kinda fuel…

Put that charcoaler with a bottom blown exhaust connected ( from an IC engine) and use that waste heat from exhaust to make “torrefied” fuel.

Any 5 Kwh Electric generator has 5 KwH exhaust heat you can use…

On top of that Charcoaler, you put a retort as in the second clip, pipe the gas to your 5 Kwh engine, and start dreaming from what else could you try…

I think, my imagination is to big ![]()

But that is the fun in life… ![]()

Koen put it real well. No (good) wood gasifier burns wood. It burns torrefied wood. WK gasifier, or a monorator gasifier, prepares its own torefied wood on demand by extracting mouisture and some volitiles out of the top layers of fuel.

I was too space limited for that on my build. So, l came around by mixing charcoal and raw wood. Chemicaly the H-C-O ratio is the same as torrefied wood, if you take the whole fuel charge in to acount.

I culd use torrefied fuel ofcorse, but for me it is easyer to mix fully cooked charcoal with fully raw wood. No need to babysit the charcoal kiln to not over or unfercook it.

One correction to Henrys post thugh. When making tofrefied wood l highly dubt the gas can be used to power the process it self. A charcoal making kiln, yes. But, at least in my observations, when wood transit from raw to torrefied it gives off mostly steam and the gases produced do not burn. Once well in to that torrefication range the gas becomes good and burns but at that point the procedure shuld be stoped anyway, otherwise the proces will go straight to charcoal.

I used front end loader to peel dirt off concrete pads , have not found all of it . I was planing on making 20 yard bin to hold dry wood chips . I still do not have working wood gas powered generator . auger failure , grate shaker failure . Best I can get is hour run . I grew a crop of Dry Beans Navy Pea . Have not sold any . Gave 25 pounds to restaurant and have not heard back from them .

I just wanted to buy Matt some torrefied wood pellets from arbaflame

Bjørn-Halvard Knappskog (CEO)

Tel: +47 21 95 41 72

Mob: +47 91 36 00 63

Email: [email protected]

Address: Arbaflame AS, Box 2934 Solli, N-0230 Oslo, Norway

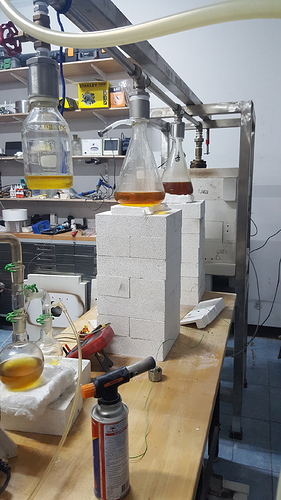

Yes, you can make a useable fuel, the easy way…

I made from heavy fuel to diesel like, gasoline like and put them in the engines… They ran, they made power. ( tested with dummy load adjustable )

Plastic waste and gasification… a good point for off grid

Are you using a catalyst like zeolite, or finding that the results are good enough without needing one?

I have wondered about taking the exhaust from an engine and using it to dry green wood. But I never bothered to look into it enough to determine what the risk of setting the wood on fire was. But it seems like a hopper which was also a heat exchanger for the engine exhaust would go along ways to pre drying wood before burning it.

i did not use a catalyst, yet, it a kind of farmer project, for villagers to turn their plastic waste into useable fuel for those funny one cylinder diesels. ( i have ordered one and waiting the arrival )

As exhaust heat is a neglected source of energy, i am using some knowhow and a lot of imagination, to use that as a possible solution.

Also applicable for industrial use, as replacement for heavy fuels ( hence the testing in my research department )

Imagine a diesel engine running on dual fuel, gas from plastic and wood + diesel fuel made by exhaust heat from waste plastic…

I have one of those 10hp Chinese diesel engines. It is in my small case ingersoll 448 garden tractor. They are incredibly tough motors the only issue I have had with mine was the fuel injector failed I think the spring was weak. But if there was a fuel source which didn’t stink as much as diesel fuel in them someone would definitely have a huge market. That is the one thing about them the low sulfer diesel fuel definitely stinks in those engines.

I highly recommend the electric starter option as well mine has a pull start backup which is a joke I have actually started it that way but only to prove it can be done.

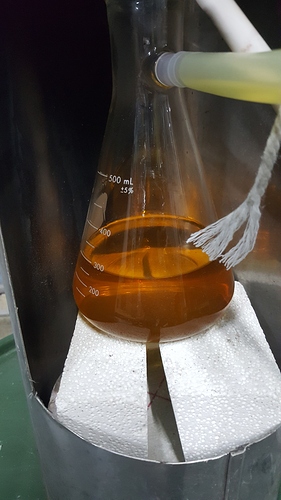

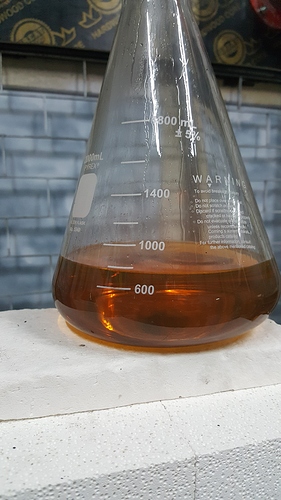

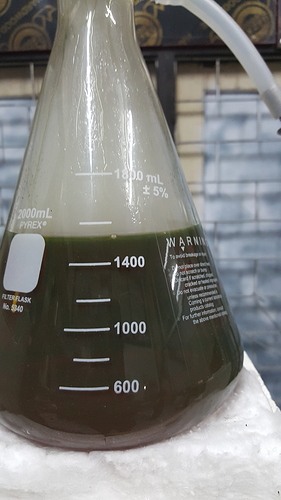

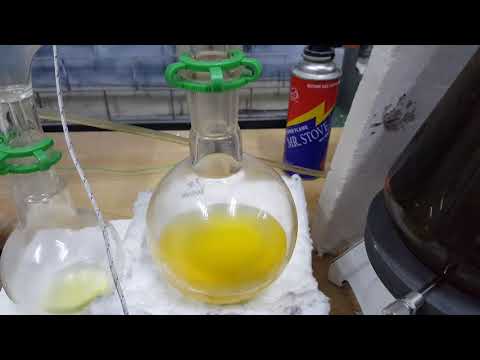

Nice pictures. I wonder what they mean or represent. I saw the one video look like he is boiling his morning coffee and distilling of the cafine or something. Sorry I guess I didn’t take the pre-recwasit for this class. TomC

Hi Tom,

That coffee is actually heavy fuel from plastic. now been boiled / distilled in lighter fractions as diesel like fuel and gasoline like… i also poored it in the 2 generators and a heavy fuel burner…

waste plastic is a cheap fuel

I glanced at a paper mentioning using biomass in the retort with plastics waste. What advantages or disadvantages do you project from that approach?

I get the sense there could be many different approaches or “recipes”.

How about animal fats or waste cooking oil added?

Edit: it sounds like used motor oil and dirty oil filters could be upgraded and cleaned up this way…

Your mention of catalysts has my attention too, I will be looking forward to developments.

I was reading that the gas that escapes the bubbler is combustible too - it could be piped and contained to flare under the retort, with an additional side flare for when the gas would cause a runaway reaction?

I also read a description of a condenser before the water bubbler, aimed at removing parrafin, said to be a byproduct of polyethylene. The article described it could be refined to candle grade, also quite interesting.

It will be a cheap fuel source, given that some of those grades of plastic apparently have no or marginal recycling options, 1, 2, and 5 being the only ones likely to be recycled, 5 a maybe.