Tom,

this is the chute through which the air flows to the tuyeres. Free space, this is the place where gas will be taken from.

Joni: So, the 4th picture in the group that I took this one from, shows the “air intake” and is that on the opposite side from the picture I posted?. So, the chute that feeds air to the tuyeres does not go all the way around the hopper/fire tube. Ok, that makes sense. TomC

Hello Joni,

I have so far watched 30 of your videos’.

My favorite so far is probably your most hated.

The 15:00 minute January 4th, 2018 video. My favorite because I get to see Jodi the gasifier Operator-man.

Jodi many of us have also had to make a system perform being timed observed presentation live on video too. In front of many people audiences.

Very colloquial: bad shit happens, always, worst, then!

You did very well under this observation. Damn - no flare! I always can make a flare. You shook down your system twice. You scraped out your under grate. Still no flare.

Then you decided to just start the engine and drive with what you did have. Stupid flare be damned.

We have all had these experiences Jodi. You made the best decision with the best results.

So my favorite video.

Now this one I will repost here hoping for a CC conversion that I can get to text translate, or use d100F Dave’s Google trick to know your words.

You are making a goals and methods statement in clear language.

5:53 minutes January 24, 2018

Hello Steve,

I have no gasoline at all, I am always on the wood. In the video you spoke about, there was a rush due to which it was possible to simply set fire to the gas generator only after many attempts. The gas gave flashes but its purity, in daylight gives a blue light that the camera does not notice. So everything that you saw happened only on wood gas.

maybe the question is not on this topic, but it haunts me … Why do you (meaning this whole forum) have popular models of coal gas generators with a descending flow, while in the USSR there were many very simple designs of gas generators like charcoal and coke with anthracite cross-gas movement with one lance? They were easy to manufacture, had water / steam supply systems and were designed for a wide range of capacities. So, the main question is why complicate your life by building complex and expensive systems in production ??? What advantages are you pursuing by this?

in the end, you can build two-zone gas generators, they will provide you with good gas, are more susceptible to raw wood and large pieces of wood, and also use coal.

I have many interesting books, although they are in Russian, but with the help of a translator I think it will not be difficult for you to read them … I will publish them today, if you don’t mind.

Hi Joni , i hope i am translating this correctly it seems you are asking us why we have to over complicate charcoal systems yes ? , if that is correct then i will have to disagree with you on that subject and say that most , not all but by far the most popular and easiest way is to build a "simple fire " so named by its creator as far as we are concerned Garry Gilmore , then we have builds from Christijan and Bob Mack with there own swing on a charcoal gasifier , plus Matt R has now come over to the dark side and is building a steam cracking generator , and in the past week we are now looking to build a simple downdraft charcoal generator .

If you have books and drawings we would all love to see them for sure , i have tried countless translation apps this week to try and get it to convert your video’s to any kind of English , but i fear non will work they struggle to keep up with the speed you speak  ,

,

Love your work and your enthusiasm all the best .

Dave

I know why you are having translation problems. I did not speak in Russian, but in most cases in Ukrainian or in a mixture of Ukrainian and Russian, which is why problems arise. All new videos will be dubbed in good Russian and there should be no problems with translation.

Thank you Joni that will explain the mixed results i was getting , it sounded like very fast talking and thought that might be why the apps were struggling to translate and now i know .

Dave

PS if your dubbing into Russian why not go the whole hog and dub in English too

Hello Joni,

This is your topic. You can ask the forum members any question here.

This DOW forum began 8 years ago. There were three areas of efforts. Roads driving vehicles. Small stationary electrical generators and engined equipment’s (like your Rebak style wood chopper), wheeled tractors; all on raw wood. And a third wood charcoal gasifiers efforts for small engines.

Other Internet forums still then existed for the all-biomass people and other “gasification” efforts and areas of interest. Tires and plastics. Theses have all since collapsed except a BBS; bioenergy.lists. All others are gone, gone now. So folks with wider interests other than direct use, pragmatic wood now crowd into the DOW too.

O.K. if they do not try and convert. And stay on their own started topics.

I; You can just not read; or comment.

The small engine efforts on wood: the primary pursuers kept making their systems too overly complex. Still having engine tarring failures. Adding more and more difficult complications to try and solve what were essentially operator problems. The fascination with more-systems-must-make-better. And many of these added complications as electronic logic driven systems subject for their own failures. Finite precise perfect 850C reduction finishing temperatures insured by the automation. Automation fuel inputs feeding. Then requiring all wood fuel stocks to be converted first with three energy intensive process steps into compressed fuel pellets.

So anyone wanting simple; then drifted toward the pre-made charcoal systems.

As the still, actual simple system.

Indeed as you point out these can be.

Then the urge to overcomplicate now drives into these too.

“Genius-minds” with busy hands makes for messy systems. This is the nature of Do-It-Yourself.

But out of this last range charcoal fuel efforts; the system of KristijanL are proving the real widest inputs range, and practical.

Yes downdraft wood charcoal then able to use up to 50% raw wood also.

An actually new addition to the Brandt system capability.

But single flowing downward vertical linear done much simpler.

My efforts are always, and always will be, small systems 3kW/th to 12kW/th for small engines 5-20 shaft horsepower. Only ON RAW site grown natural form WOODS.

With the ultimate capability to use all times of the year, found raw wood. Not just short season solar dried woods.

Thermal dynamically this is very possible.

And yours so far are the ONLY showing this capability.

I can also do this on small stationary system using all of the internal combustion engines waste heats; the electrical generator wastes heats; and generated gas waste heats close coupled to pre-condition the 30% to 60% wet wood stocks before the gasifier.

My system is rejected as it requires the operator to stop sleeping/ignoring, and WORK shift one-load batch baskets of wood fuel along progressive drying stations. Until the last position shift into the gasifier hopper/fuel bin. As 10% moisture dry hot wood. The the actual gasifier can be extremely simple.

I have very carefully NOT used names, or pictures, to illustrate my points.

Many of these fellows with different approaches are my friends.

And this is an old traditional, very American attitude:

Everyone is allowed to pursue their own interests.

To success. To failures. To over-complicated impossibilities. It WAS their own choice, granted.

Ha! Ha! To them, I say. Just do not ask me to sing your songs. Maybe, I will. Maybe, I will not.

Listen; maybe. Silently walk away. Ignore; most likely. And That is my American choice.

Steve Unruh

Hundred likes to you Steve, very well said.

I might add that this is everyone’s choice on the drive on wood site any place on this planet we call earth.

Bob

Hello All, I did not mean for my last said to be an ending.

Too long, yes.

But how else to say??

I have edited it six times for better translatability.

Jodi, restated all here on the DOW who actually DO . . . do because they must.

It is not a lack of historical knowledge.

Even as a design engineer DOing, and then useing; it becomes a cut&fit try, try, try to improve.

In post #57 when you said that you did not believe use of “the recovery zone” was for modern systems, I understood what you meant.

That inlet air heat transfer was a waste of effort.

You are not alone in this belief.

Central dry, dry, cold, cold Canadian Greg Manning; U.S. Steven Abaddessa; recently deceased New Zealander Doug Williams all do not like air preheating. They claim that the cold air is denser with more mass, and more O2 molecules. They externally chill their inlet air. There are devotees who use their systems principals on engines with successes.

Then there are others who insist on massive systems pre-heating, and heat recovery recycling. Also with engine running successes.

Then those who insist on 4-6-8 channels of digitized controlling as the key to successes.

I have operated all of these now to engine loaded running.

What in my opinion is the key to success?

Operator, Operator, Operator, System.

Or . . . System, Operator, Operator, Operator.

Or any other combination of these in this proportion.

And proud Designers hate those of us with this belief system for saying this.

But on the DOW by those actually DOing, and Using, this has become the predominate success wisdom.

S.U.

Yup it is better to meter down for higher velocity than it is to preheat in my opinion I did extensive air preheat systems on early machines and it drove complexity and cost very high with little effectiveness. Well over 250 machine builds prove this. Higher localized air penetration is far better than slow velocity air preheat and its already a hell hole in there anyways, What little heat is in the intake makes little difference. Physics!

Hi Matt, it takes wasted energy or fuel calories to get the heat up to cause the air to make combustion. In a diesel you need glow plugs to heat things up to get it started, but you do not need them on continually just to start.

I think we are comparing apples to oranges here.

Now my WK unit has all the fancy preheated air on it. The last Argos Event on traveling across the USA, my muffler preheater heater box failed hot engine exhaust went into the air side of the box , muffler hole. This heat melted down my air intake flapper valve and 2 blowers under my truck. No more plastic being used there. That was some really hot air it all happen traveling though a cold rain and hail storm. Thank you Yehovah God it did not catch on fire in Yeshua Name. I had to run my unit on no preheated air at Argos. It was a longer start up time for me. Maybe as long as 20 minutes for me, before felt it safe to go down the road I have never run the truck like this before. I also had brought a big bag of extra charcoal along. The inside of my gasifer was wet. I had to dry it out, what mess but got it working it ran fine. Especially with the rocket fuel that Kristijan showed me how to mix up. I did notice I had to refuel the hopper more often, less miles to the hopper. Why? Energy or calories being used up to bring it to combustion temperature in the fire tube.

As a fire fighter for the US forestry in my youth. We learn the basics of put out a fire. Take away the oxygen, take away the fuel, or take away the heat. With out those basic three things you have no fire. Simple. The hotter the air the easier for the fire to combust and burn. Moisture and cold will retard the fire both take a way heat… So will restriction of air cold or hot. I have heard over and over from most of you saying it is a balance between all three that makes a gasification work. And these factors are not fix valve.

Bob

If you take heat from the unit to heat the air this an energy transfer. There is always a loss in a transfer of energy. You are better off insulating and keeping that heat inside. Air is extremely efficient at absorbing heat I doubt you are really making any difference. We did all this and the cold air machines worked better same architecture but just a simple manifold instead of heating with the reduction. But also cost is big factor this is already a hard a sell and adding this revision is extremely costly and complex. Try to hire people off the street to build a gasifier in a manufacturing system that is way under developed.

What I think is really happening with preheat systems. It is not bring that heat back into the unit itself. It is basically a form of insulating the unit. Instead of that heat radiating out, the air absorbing so it cant. If you just insulate you get the same effect but you keep that heat where you want it. That is your reduction. The oxidation zone does not need help just use good fuel that will burn hot. The physics of the reduction process is the real culprit that is fighting us.

I am glad the failure of these parts did not have more serious consequences . I just did not realize I had the failure till I stuck a flame inside gasifier and saw air flow .

This machine had a something like a 100 lbs of refractory cement in its walls. It was crazy heavy. No air preheat and to this day it was the best performing direct fueled system I ever produced. But the build was not doable for manufacture. I think we had 8 months into that build. But at that time was when the company really blew up too. So I had my hands full.

Okay let’s get back the title on this topic. Joni gas generator, version 8.0 (GJ - 8.0)

We all have our own threads with topics. Sorry Joni for hijacking your thread. Sometimes I just get off the subject.

Bob

Hello everybody!

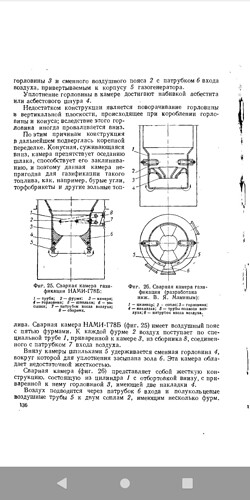

Here is my answer to all your technologies, I think you shouldn’t go further than this design, it’s simple, cheap and very reliable! Such a gas generator is suitable for any fuel or its mixture.

It’s like SteveU said about the builds in the Ben Peterson books. Solid proven designs but apparently not his premium work. I’m sure the design you posted above is an good reliable design but where is the fun if you are not tweeking and experimenting? One of the things I like most about this site is that everybody is trying out ideas. You have to sift through a lot of dirt to find any gold.