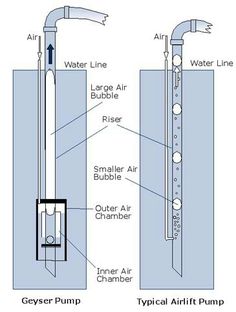

What Steve said. I missed seeing your post earlier. If you look online there are companies dealing with the Amish making wind powered air compressors. I think it’s a good combo. Wind is a relatively poor source for most offgrid. Either there’s no wind, or too much, and probably not when you need it. So the rated power of a turbine, especially back yard scale, is rarely met. The old high torque water pumpers would be perfect for compressing air. High start up torque would be the thing there. The big advantage of compressing air is wind gusts and over power situations which wouldn’t be useful for electric generation or charging batteries will nicely be converted to compressed air. Same on the low end of the scale. And though compressed air is relatively inefficient given the thermal losses of compression, this is free energy with indefinite storage, no discharge losses.

As for vertical axis vs horizontal, from what I read that was settled decades ago. 3 blade horizontal axis is the most efficient. Any vertical axis machine has to push wind to get the blades back into power producing position. A vertical axis machine does have the attractive feature of most of the maintenance requiring parts can be at ground level. Harder to design good shaft support for a vertical axis machine too, probably needing guy wires.

As for inefficiencies from thermal losses with air, why not reheat the air with a charcoal burner inline? Sounds like an appealing combo of renewable energy hobbies…

) or if it gets windy and cold.

) or if it gets windy and cold.