Now my only problems are to find a sturdy 55 gallon drum with a locking lid.

The ones I had bought from a gentleman were of the non ribbed variety and are of a very thin steel. I could move the walls by hugging it so I’d be afraid of what vacuum forces would do to it. I’ll just use them to store my char from now on.

Everywhere I search, people have tons of cut apart barrels but no in-tact barrels with lids. The lids for the drums I bought won’t fit on a solid one I got from my workplace, used to hold Brake Kleen but I’ve cut the top with a non sparking opener.

The solid topped ones are much thicker steel and are ribbed like a normal one, but the diameter of the lip is just a little too big for the other lid to seal. Maybe if I spread out the lip on the lid it could fit.

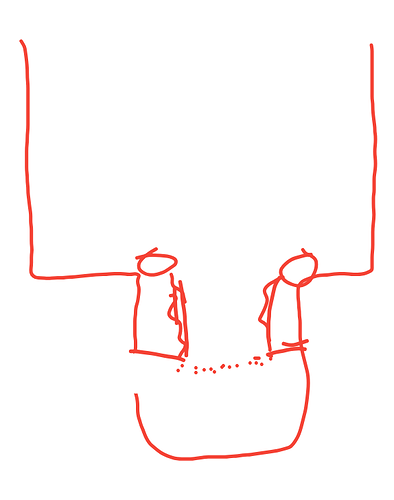

I can’t source any decent 55 gallon drums at the moment but I do have 3 20lb propane tanks that I have already prepared for cutting into or welding on, and I have a 20 gallon steel drum with a removable lid. I was thinking of adapting @KristijanL drawing and here’s a rough draft of that.

The opening at the bottom denotes my gas out, propane tank will be insulated with ceramic wool around the burn tube area, and most likely a fixed grate resting on legs from the bottom of the propane tank and a loose screen protecting the gas exit. I’ll allow the grate to have some wobble so it will shake as I go down the road.

Yup, it seems like there are people out there that make little businesses out of recycling old containers. I suppose they go around grabbing up all the good stuff. Near me there is an outfit called Container Reclaimer.

Rindert

I FINALLY found some barrels so I bought 4 55 gallon drums and lids with locking rings. They all seem pretty intact with some minor dents. Proper barrels with the stamped rib rings for strength. Had to go into South Carolina to find it but I live on the border of NC and SC anyways.

I need to find my sketch paper and attempt to draw up a rough draft of the gasifier before I go cutting any holes.

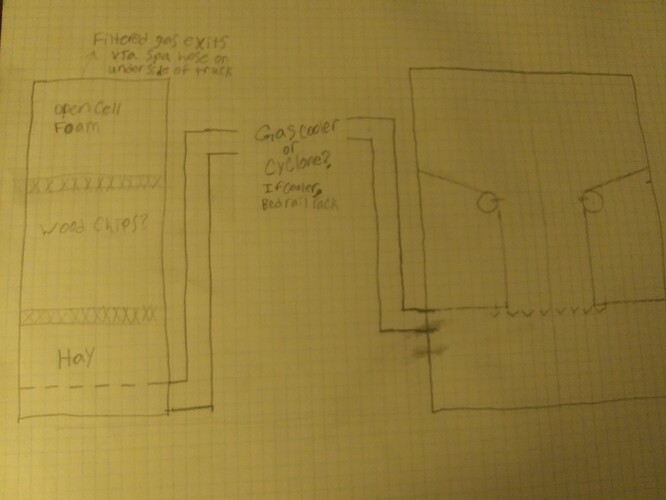

Here’s a really rough draft. Gasifier is somewhat to scale, each grid square is one inch represented. 8 inch diameter burn zone and 8 inches tall, with 2 inch diameter steel pipe for the ring flute nozzle. I’m not sure if I just want to weld legs onto a grate or weld tabs for the grate to rest on. I’d like to make it so the ceramic wool cylinder can be pulled out and simply resealed with refractory or muffler sealant along the seams. Perhaps that’s asking a bit much for this design though. I think for the ash cleanout I’ll weld an ammo can into the side near the bottom utilizing the lid as a service door. I’m also considering the flow being 1. Gasifier, 2. Gas cooler running along the rail of the bed, 3. Filter, 4. Cyclone mounted in the engine compartment for final moisture or ash removal.

My main concern is accidental moisture from humidity getting into charcoal, or also moisture from mixing a little wood into the coal.

Hi Cody , hope your going to be taking lots and lots of photo’s while you are building , love seeing the progression of a new style build and this double flute is of interest to a lot of us .

If i can make a small suggestion , looking at your sketch you mention its sort of to scale and so gain a extra few miles run time by lowering the inside 8 inch tube lower down , don’t bother welding a ammo can on the side as the amount of ash is not a big deal ,instead make it so your gas outlet pipe can be unhooked quickly and if its 2 inch dia outlet it will give you enough room to put a vacuum cleaner hose in there for clean out , just leave about 1 inch of ash on the bottom for insulation .

Dave

I might make it a double flute, but my initial idea is to make a ring out of steel pipe with holes around the inside to create a circular burn zone. I might try to attach it with a pipe union for disassembly though, or a slip fitting sealed with muffler silicone.

Cody,

I didn’t know you live in North Carolina. Me, too. If you come my way, I’ll give you a ride in my charcoal-powered Corolla.

I’m out Kings Mountain way. Not sure of your whereabouts. I really like your Corolla build. Makes me want to buy an old Corolla or Civic and turn it into a Ute with a simple fire on it.

Progress update. Bought some very thick structural pipe. Couldn’t find 2" inner diameter but I did find 1.5" ID pipe. It is 2.5mm thick pipe. My ring roller cannot roll this tough stuff so I’ll have to go with a double flute design. I just hope that it will react fine with a round firetube instead of a square firetube like how Kristijan had proposed in another thread.

The charcoal gases you make with a cylinder firetube will not care about the shape as long as the charcoal flows between the two flute pipes.

Bob

So instead of about 11 inches from the grate to the bottom of the barrel, make it about 4 inches? Or do you think it should be 6 inches?

I’m halfway tempted to build a grateless system, but I’m imagining the grate standing on legs to help hold up the ceramic wool insulation.

Cody , as this is a downdraft charcoal gasifier and as far as i am aware no one has yet built and run a double flute designed one yet it will all be trial and error i think , so sizing spacing ect will all be suck it and see i think , but if i can ramble on with a few thoughts in my head i am sure if i am wrong someone else will put me straight .

In your drawing you are showing the gas out pipe right under the grate level with the 8 inch restriction pipe , so if you say there is 11 inches too the bottom of the barrel then lower everything down and leave 3 or 4 inches from the bottom allowing 1 inch of ash in the bottom you will not need any other type of insulation at all other than ash it will also save you time and effort by using the gas outlet pipe to suck out any large build up of ash with a vacuum cleaner , this will then allow you more area on top to load more fuel in and so longer run times

If i got this wrong then ignore it , but as far as all the charcoal systems i have built so far i have not had a need for any type of ceramic wool insulation at all as they were for stationary use and ash and charcoal insulation works just fine , unlike Kristijans unit that used ceramic insulation in his unit due to it being in a confined area and stealthily built where he did not want all that heat exposed inside the boot of his car .

Dave

Woops did i just make a big boo boo lol i just noticed the title of the thread !

Sorry Cody i forgot your unit is for your Mazda ignore me i am old and senile for some reason i was thinking stationary application .

Dave

The ceramic wool and refractory will be forming my fire tube, everywhere else will be left bare. Just wanted to clarify that.

I’m thinking of making the grate sit on legs to raise it off the bottom of the barrel and hold up the ceramic wool burn tube.

I figure I won’t need a grate shaker since it will be bumped down the road, and where I live there are plenty of rough patches.

Good Roads State my buttocks.

Oh right , sorry i did not realize you were going to make the tube from refractory , i just imagined it would be mild steel pipe , you must have a reason for the refractory i missed .

Yes the grate would work fine sat on legs a few inches off the bottom allowing room for cleanout .

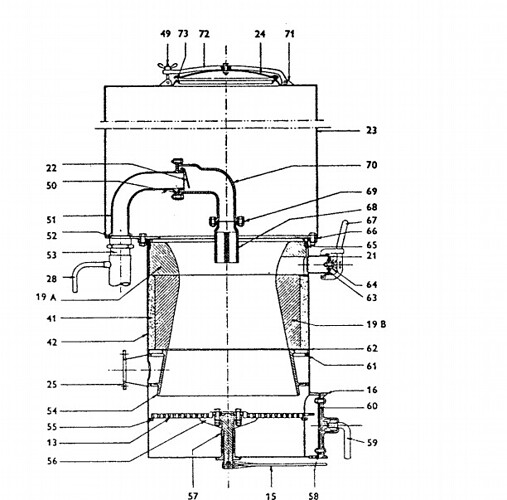

If all else fails with the double flute system I can always try to copy a Svedlund char gasifier.

I have 4 newish barrels with lids so I have some room for fudging it up.

And by copy I mean copy the air intake section not necessarily the entire build.

I can not guarantee the 2.5mm thick wall pipe will not burn trugh, my guts say its gonna overheat. You realy need mass here to work like a heat sink, dtaw the intense heat away from the nozzle tips and around the nozzle where it gets picked up by incomeing air. Its the only cruicial dimension of the build so you mind want to invest some more time in finding a thicker one. I usualy go about 8mm.

If you wish to go round, why not male a compromise and make it octagonal? Cut wedges out the pipe and form the shape then weald it together.

As for grate clearance, l have run as litle as 2". Height is super important when it comes to mobile applications so squeeze every mm out of it.

My 1" clearance gasifier was designed so that the high velivity of gas wuld sweep the ash from the bottom under the grate and carry it in the ashbox on the side of the gasifier.

Deciding to go grateless or not, keep in mind this gasifier WILL make slag or at least lumps of ash. They must periondicly be either pulled out or sliped trugh the grate. If they build up in the sistem it will mess things up.

I might try to go for an octagonal shape.

What I might do is press two close fitting pipes into each other to double up the thickness. I have a 12 ton press and I’ve done it to make a front axle for my homemade diesel “yard truck”.

Only issue is finding large enough pipes, maybe I’ll have to order them online because the biggest sizes my stores have is 1.25" ID plumbing pipe, and it might sleeve a 1" ID pipe very tightly. That should bring up the wall thickness to about 5~6mm. The thickness varies on the size of the pipe.

Also slag is the reason why I want to weld an ammo can to the side so I can get to it with a scraper and do more thorough inspections.