Kristjan

How high up is the fuel pump in the tank? Is it high enough to allow that much water to collect under the gas without the water getting to the fuel pump intake?

Jan, exactly my thinking on the flute nozzle. Enough mass to conduct the heat away from the destruction zone while not wasteing it, like a WK.

Don and Garry, indeed, kids seem to like water  however the cap on the fuel tank is so stiff even wife cant open it. It has to be, its a pressurised fuel tank.

however the cap on the fuel tank is so stiff even wife cant open it. It has to be, its a pressurised fuel tank.

Thinking about it, l think lknow what appened. I had no problem starting the car every day but if it sit for a day or more it wuldnt start. I think while runing, the pump and return line emulsified the water and siting for a long time alowed te water to separate.

Jakob, the thing is this system hes a externel fuel pump. The fuel tank is just a canister with outlet on its lowest part. It only has a fuel level flloat and a mesh inside.

Ok, so likely water contaminated fuel from a fuel station?

I can’t see that degree of condensation, especially in your mild climate.

I agree on the water contamination fuel from a station, it has happened to me. You will not notice for a couple of days after the vehicle has sat not running. I would put some heet gas treatment in it to clean it out.

Bob

This is why I try to never put gasoline in when the fuel tanker is delivering fuel at the station, it stirs everything at the bottom of the storage tanks.

Hi Kristijan,

sorry for the problems with you gasifier but great to see you developing it further!

On my computer, I could barely understand what you were talking about as the speakers are not good, but from whait I see I understand that the restriction above the nozzles is the damaged part, right?

Everything else is still good in shape?

So, why not just remove the restriction between nozzles and hopper?

Another suggestion: Have you thought about something like the Svedlund-design with a nozzle pointing downwards? Probably combined with an “umbrella” to prevent direct contact of glowing char with the nozzle as Max Gasman suggested it:

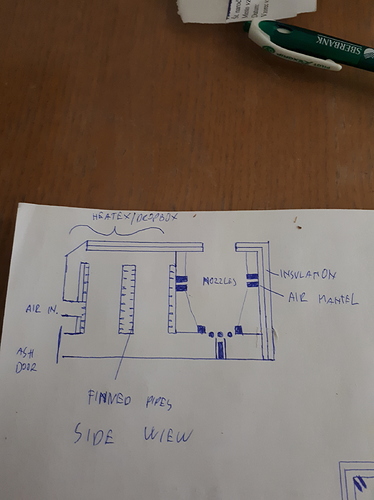

Based on this, I made a scetch some time ago for what I was planning for the Land-Rover:

Well, life kept me busy so I haven’t started yet and I cannot present any experiences about this nozzle design yet, but I think it is worth a try.

Anyway, I’m also curious how a flute nozzle will behave in a downdraft system.

Please keep us informed and keep on with this very interesting project!

Regards,

Til

Hi Til.

I am sorry, it seems te blame is on me. I didnt wach the video prior to upload, sound is real bad.

Yes the top restriction is the only dameged part but its made of 4 lair of sheet steel, air circulates in to keep it cool. Cant just cut it out becouse it is there to keep the heat from rising in the hopper and reneewing it wuld be more complicated thain making a new gasifier.

Well there is a big limitation l have vs most people. I need to fit a horse in a dog house, if you know what l mean. The gasifier must fit in a compartment of 60x30x27cm. Not enough room for any clasical design so l have to experiment with different styles.

Regarding the bell nozzle, l am afraid l see some problems with it. I hope not to discourage you from trying, but the thing is in suc extreme heat most of it is radiated rather thain conducted. A few cm of space between the nozzle and charcoal will not reduce radition much… but like l sayd, its just my thods!

Hi Kristijan , its a shame you have to rebuild , but at least thats how we get to make better systems ( fingers crossed )

You mention that the nozzles were too high and so heat was rising upwards ,how high above the restriction were your nozzles then ?

Dave

Hi Dave. Exactly. This is the first system l built l was 100% satisfyed ith performance, pitty it got ruined. Learning from mistakes.

Not sure. I hink it was 15cm, and 6cm from nozzles to top restriction. Too litle.

Thanks Kristijan it helps my mind work out better seeing your drawing .

I am at the beginning stage of building a simple downdraft and playing with designs in my head and idea’s supplied by every post i have ever read ,i may even try with 3 nozzles above a restriction and grate like yours , but being a static unit i will have a lot more height and depth to play with and will only be running engines up too around 500cc .

Dave

Hi Kristijan,

thanks a lot for your answer.

I always enjoy looking at your solutions and I’m curious which new features you may find.

I just want to try the bell nozzle, as Max really promoted it again and again. In the end, I will see how it works.

If I have seen it right, you plan to fit two flute-nozzles opposite to each other. Are you planning to place the holes sidewards or downwards?

The flute nozzles is a very clever and so simple solution, I’m really looking forward to see it an a downdraft gasifier.

Til

Isopropyl alcohol works ok too, but not with 1/2 gallon. Occasionally we see that happen here. Underground fuel tanks at gas stations. Or a truck gets contaminated etc. Once we had a contaminated pipeline with lots of water in it. I think that was after Katrina hit New Orleans. It’s hard on a gas station when that happens. They lose all their business for years.

I once had an old car that would get water in the tank if I drove it when it was raining very hard. This would not happen if it was a light rain or snow and it would not happen if I did not drive. Finally I discovered that a rubber fitting in the fuel filler neck was old and cracked. I replaced it and no more problems.

Rindert

Half a month has passed and l still havent found time to start building. But l take it as a good thing. Gave me time to rethink my plans.

Since l am again chaneing the system, l must put everything in to account. And make some sacrifices.

The fact is l have a big family and this is a small gasification platform. Trunk space is important.

So, the fact is 80% of my driveing is within 15 mile range. The rest are real long drives, on wich l usualy run out of fuel anway and need to burn dino. So, compromises.

I will reduce everithing. Starting wih fuel size. This dictates the dimensions of the gasifier hearth wich is a huge deal here. I will focus on chip/char mix for everyday use and pellets for long drives.

With pellets 2 to 3 times the range can be achived vs chunks or chips per same volume of hopper. Huge deal here, althugh not free. Still at least 50% cheaper thain dino thugh.

Anywy, thets the plan for now. Might change till l get to it

Comments and thods apreciaed.

Those nights of ‘‘thinking’’ can wreck a good nights sleep. This story won’t help you, but I’ll tell it anyway. I started out using a 55 gal. drum for my hopper. On the way home from Argos, I had such a head wind that the V6 would hardly keep the truck up to speed on petrol. When I got time I cut 7in. off the hopper, but it still stuck above the cab. This rebuild, I took it down to the cab height. I made a LOT of changes to the gasifier also, so I don’t know w what had the most affect in improving the performance. Like you, I decided most of my trips are about 15mi., and some will be 60mi. The worst would be if I wanted to take it to Argos. TomC

Kristijan, I don’t feel comfortable giving advice on char, chips or pellets. Only you know what will give you most “bang for the buck”. Cost, use, effort…

…Maybe even reinstalling the small charcoal gasifier on the Seat and run the MB straight gasoline on rare family trips would be an economical option?

Skibox or trailer for occational extra fuel or luggage, are other options.

Oh, what about an external “skibox hopper” on the roof rack for longer trips? Open a valve and pour in fresh char

Well either way the gasifier has to be a downdraft and the Seat gasifier is not. When you burn 350 pounds of char a month sooner or later you WILL encounter a partialy cooked peace and all the tar will end in the engine. There are pros and cons thugh…

Thats the other thing. I am faceing some interasting times and l do not know if l will be able to keep up with the fuel production in the future. In those ocasions l want to be able to use pellets instead of diy motorfuel.

Thats a possibility allso

If pellets are so costly there, maybe you should have a pellet mill? Then perhaps you can sell extra pellets. And you can make pellets from hay that was rained on. This is just thinking like a farmer.

I went shoping today.

I have the crude arrangement in mind, make a wk style finned outside of the pipe etc. First plan was to make 2 planes of nozzles and a narrower, taller firetube. Imbert style, maybee inverted V. Targeted fuel is small woodchips and pellets. But looking at the pipe, it occured to me this culd allso be a WK! The pipe is 7"id with 9mm walls. 33cm long.

I wuld apreciate some advice. What do you guys vote for. Imbert or WK?