Mike,

What you say makes sense. But that’s that way Joni does it. And SUCCESS.

So what do we do in a case like this? Maybe just say it works.

Rindert

Just one thing… this led me to many head scratches too at the begining.

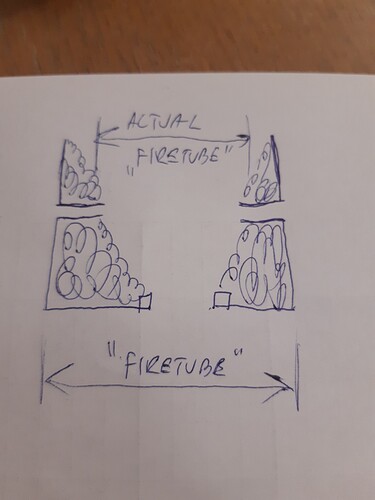

What we call a “firetube” on a lmbert gasifier is not realistic. The point behing protruding nozzles is that ash and char builds up behind them, for insulation reasons. This means the actual firetube is the nozzle circle. Only there fuel actualy flows down, not behind the nozzles

Hi Michael, Oh remember @Ron_L his tracker gasifer had nozzles that point up and out to the fire tube to help stop the bridging in his hopper. I do not remember how far the nozzles protrude inwards.

Bob

Kristian; Yes you are kind of, sort of, partially correct, BUT, I much prefer a mechanical device to keep the gases from going behind of the nozzle. A tar fence of one sort or another. TomC

We need to remember that if this was a charcoal gasifer the nozzles will melt at the tips. In a wood gasifer there is a abundance of moisture. The nozzles are pointing at the center of the firetube the velocity of the air helps keep the charcoal from touching the nozzles, ash and char is involved too. The air is shooting out of the nozzles hitting the charcoal and reflecting back at the nozzles. The air has to go around all of the charcoal pieces to even get to the center of the fire tube, it is also being drawn downwards away from the nozzles . This is what causes the turbulence that Steve talks about. The other thing to remember is the restiction opening that is smaller then the nozzles tips circumstance, the cone shape. This causes the velocity speed to increase, more heat. Because it is drawing from a vaccum it will follow the flow of the path of least resistance. Behind the nozzles tips is a vaccum not much it is the hopper vacuum. The center of the lobe is HOT 1000 to 2000 *f . Once it reaches the reduction ring opening the velocity slows down going through this opening, causing cooling of the gases velocity slowing down. The gases are at around 800 * f leaving the gasifer. The metals and welds need to be able to handle this, the cooling down of the gasifer at shut down and start ups and running of the gasifer repeatedly.

One other thing that is not mentioned is nitrogen gas. This is a protection gas because of the inert gas quality it has in its make up.

If you would only have oxygen gas go into the gasifer it would be much hotter may be melting the normal metal nozzles tips I would think.

Bob

“We need to remember that if this was a charcoal gasifer the nozzles will melt at the tips.”

You sure about that?

Mute the sound, mi microphone was dead. Anyways, you can see even after many miles of charcoal use and abuse, the nozzles are intact. All but one that is, that was my fault (wrong light-port position). The only reason the gaifier was scraped was due to a crack above the actual gasifier. Otherwise it was a beast of a machine…

Edit:

Ha, right at the end of the video, you see the birth of the double flute downdraft gasifier idea! Unfortunaly l never (yet) got to building it…

To tell the truth l my self tend to forget how it was made  it was a gasifier, heat exchanger, dropbox and a muffler/tailpipe all in one

it was a gasifier, heat exchanger, dropbox and a muffler/tailpipe all in one  but it was probably the best performing gasifier l ever had.

but it was probably the best performing gasifier l ever had.

Staying on e topic, @Joni, this looks familiar?

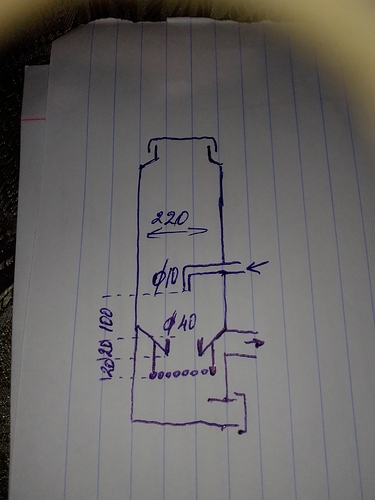

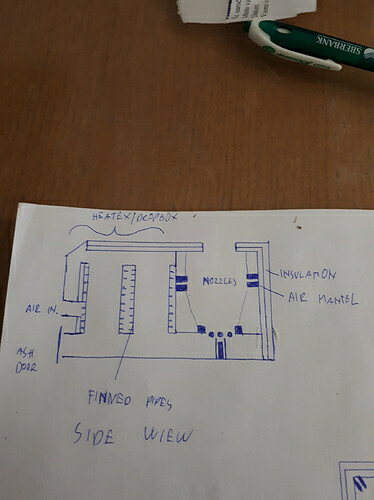

this is the schematic of that gasifier.

this is the schematic of that gasifier.

I find this design that Joni and l used has a lot of potential too. Now, Joni will be mad when l say this design only works (safely) with charcoal mixed in. But in fact he does exactly the same him self! Just the other way around.

Gasification is nothing but finding the right ratio of carbon to water, simplified. Raw wood has a bit too high of a C/H20 ratio for ideal gasification. A litle bit too much water (not even takeing moisture in to a count here- just chemicly bound water). Couple of ways to deal with that.

Mr Wayne condences the excess watter right from the hopper.

Imbert heated it, passed it unreacted trugh the hearth together with the gas and collected it in the gas cooler.

Joni evacuates it out the tailpipe.

And l, instead of iliminating the water out of the equation elevate the carbon/water ratio by adding charcoal to the mix. The resault is THE SAME! Or in Mr Waynes terminology, “many ways to skin a cat”.

Difference is only in what one needs and can afford.

Wayne can afford space and air cooling/condenseing capability.

Imberts can afford huge hot hoppers that bake the wood for a long time till it combusts.

Joni can evacuate the smoke out the hopoer trugh tailpipe.

And l never culd do any of those things, haveing the sistem in a sedan trunk and some preety strict enviromental laws… So l made it work the way it suited me, but it might not suit anyone else!

Steve, belive me, those days l wuld not mind at all to have a litle soft wood forest here instead of having all hardwood forest. It gets tricky hammeting a nail in most hardwoods… l need to hammer a few hundreds…

Thanks Kristijan .

Very well written

I think about Joni’s gasifiers. How does this not bridge?

Perhaps because his nozzle is on a long, slender pipe attached to a thin housing. So then perhaps the nozzle actually vibrates up and down and bridging can never happen?

Rindert

Hi Kristijan, I thought your gasifer was mainly charcoal with wood mixed in, if not than I stand corrected. But most of the gasifers that are just nozzles made of carbon steel have problems unless the heat can be pull away from the nozzles. Down draft seems to work differently then updraft, or cross flow gasifers.

Bob

You sayd it right there. Draw the heat away. This gasifier was designed to do that.

I run anything from dry charcoal up to about 50/50 wood mix. Even tryed 100% wood once but got a slightly tacky throtle in the morning so l decided its not worth it.

Been laying awake thinking about your gasifier K L. I’m glad to now have the schematic but I am still puzzled about some things. I did have a hard time hearing some of the audio in your video. Seems like you said that the ceramic blanket was inside the reactor up to the bottom of the nozzles. Then the drawing shows insulation between the outside of the box and the air mantel. You have a finned pipe on the left side of the reactor in the picture. Does that pull air up from the bottom of the pipe to preheat the air and feed the nozzles? Then you mentioned using the gasifier as a muffler. Doesn’t that create back pressure at your grate? Right now I have only studied the WK, Simple fire and the Don M designs. Still trying to figure out some of these others work. Now I have to go back and figure out what you said was flawed about this design.

I have not had much time or the band width to study Joni’s designs in any detail. The one thing on the one design I’m curious about is the nozzle ring. This seems like a good idea but provides none of the preheat integral to a design like the WK. Then I have read the Ben P comment about the Philosophical dispute among builders over the importance of pre-heated air. School me please.

Sorry for your sleep deprovision.

The cheramic wool was both behind the nozzlesand around the actual gasifier.

Exactly. 4 vertical 4x4" finned pipes were both used as a dropbox for ash and air preheat. It was werry effective.

Ha, mufler. This gasifier was the muffler officialy  l threw the original out and put a gasifier in its place. Then installed a pipe runing trugh the actual gasifier, comeing out trugh the back as a tailpipe. This had nothing to do with the gasifier and was completely separated.

l threw the original out and put a gasifier in its place. Then installed a pipe runing trugh the actual gasifier, comeing out trugh the back as a tailpipe. This had nothing to do with the gasifier and was completely separated.

Hey TomH,

This Krisitjan explaining started at post #60. Mouse/scroll wheel back up watching the RH side number block.

He was refuting that his hard ran system would have a melting problem at his nozzles. But instead have plate steel jacketing heat failure.

His diagram shows that he made this double walled sides and top. In between these wall he drew the air to attempt to keep his outer wall cooler.

Then in the video he shows WHY the need for contact cooling and even insulating because of his in-the-trunk stuffing.

I figure air-pre-heat was not his priority. Pure charcoal systems do not benefit from it.

Audio works much better for us old half hear loss guys with a good set of in the ear buds; or a good set of over the ear head-phones. The you can isolate out all of the other outside noise makers - KIDS! (wife) and jack up the volume. Computer speakers suck.

Steve Unruh

And Now because Kristijan was forced to think inside a very small BOX due to his circumstances, he said here; or on another topic, that he learned things he would not otherwise tried as “not typical”.

And he became another independent Proof-point of my wood gasification Heat premise for calculating power.

And I will say this again and again. WayneK’s; Kristijan’s; Koen V.L.'s; and now Joni’s. Successes are as much because they have put in the wide range of using operating hours to make their systems sing.

Ain’t no magic system jiggering that can substitute for this kind of experiences.

Superior gardeners are said to have a Green-Thumb. Superior cooks said to have had a great Mother, Grandmother behind them.

I say bullshit. They became superior because they put in the hundreds of hours to become good. Just like a superior metals welder.

And there is a Brotherhood-of-the-Blackhand of Gasification. You earn your way in.

Operating Useing: blackening those hands.

S.U.

Success makes you smile , failures makes you learn

A few days ago, we talked to Kristjan about the composition of wood and the course of the oxidation and reduction reaction. According to the molar composition of wood 6% H … 44% O … 50% C … this is supposed to mean 3xH2 … 2.75xO … 4.17xC, if we look at the oxidation process and the reductions eventually give 2.75xCO and 1.42xCH4 and 0.32xH remains, which means that if oxidation takes place first, some oxygen must be added, which in turn forms an excess of water in the process. Kristjan is very right when he says that charcoal should be added or steam should be discharged

Pipe I had as single nozzle for gasifier . As a fix for leak that caused all gas to burn in gasifier .

Fixing that caused many more leaks , results of which I am yet to experience . What , were and how much .

Hello Mr. Steve, thank you for your effort and writing. I am one ordinary average person trying to understand the basic processes in wood conversions so that I can then design and operate a gasifier well. I’m a little ashamed if someone addresses me with “sir”, because I’m not worth it

Ha! Ha! You, Sir are far from average.

You have shown us your whole house hydronic system. Fueled by your own made wood chips.

And average person just turns up their thermostat and sends off more money each month to the actual energy suppler. Not become their own energy supplier.

S.U.