Yes you are right, l forgot to mention the restriction is the only thing l dont weld. It just sits in a gasifier and can be pulled out, like a WK choke. Insulates and seals its self with ash.

Well the way l see it you have 2 options. Make a gasifier out of materials that can withstand the heat, take all the different expansion spots in to account… do not weld! let the heat hang in there and hope for the best. Example is old time ww2 gasifiers, cast iron hour glass of cheramic hearths. Good for the flywheel effect.

Or, make the heat conduct out of the critical spots and distribute elsewere. In the intake air per instance. The importance here is to have enough mass on certain places that can conduct heat fast enough. WK is one clear example of that, or my flute nozzle for a char gasifier.

Nozzles… l used thick stainless bolts drilled trugh. After many hours and many miles they still had the burr from drilling. Charcoal is a different story, using it pure did erode my inch thick ss rod with a 9mm hole…

Me and Tone talked on the phone the other day, discussing possibilitys for a good gasifier. He laughed when l sayd for me, the making of the gasifier hearth is the simplest part and l stand fully behind that statement. Its things later on that are a pain to make right, cleanout ports, filters, mixers…

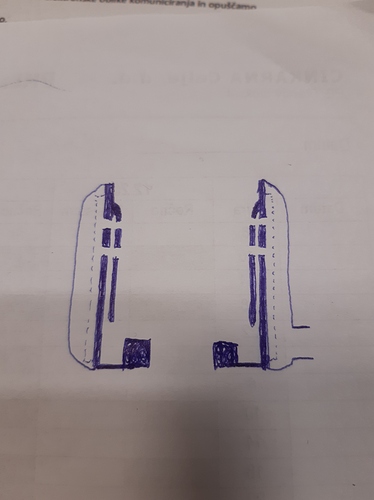

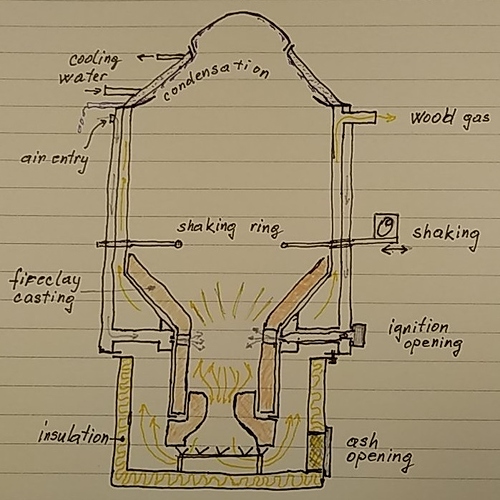

This is a example of how l imagine a simplest, bullet proof raw wood gasifier hearth anyone can make in a hour or two

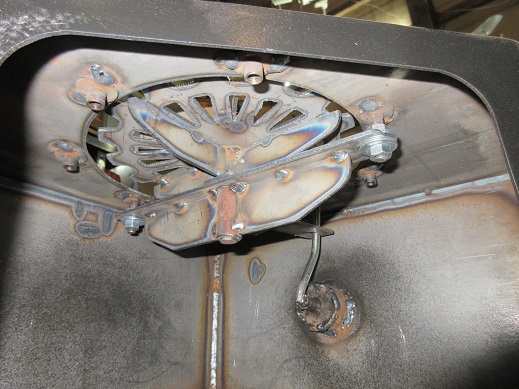

Thick firetube, thick nozzles, welded strongly for a good thermal contact. Thick restriction sits on a shelf. A DOMED air mantel around, air intake at the bottom in a tangent like a cyclone for good turbolence/heat pickup by the air.

Grate not shown here!

I use this design now, but on stereoides  reason being l wanted to make a hybrid gasifier that can run anything from raw wood to pure charcoal, but prefferably a mix of both.

reason being l wanted to make a hybrid gasifier that can run anything from raw wood to pure charcoal, but prefferably a mix of both.

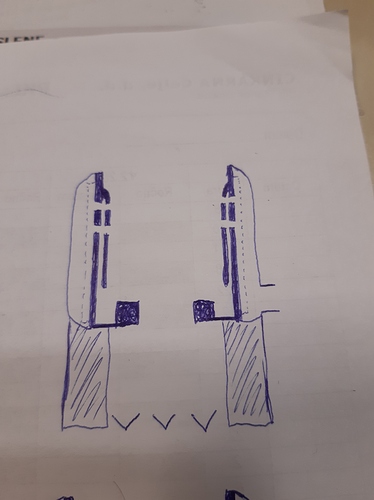

9mm thick firetube, double level of nozzles, super thick restriction. In contrast to the original concept, in spirit of making the gasifier withstand pure charcoal l allso added finns on the firetube and welded 6mm acid proof stainless sacrificial plates inside the firetube. Probably overkill but l wanted to see how they perform.

In a way it uses some concepts of a WK…

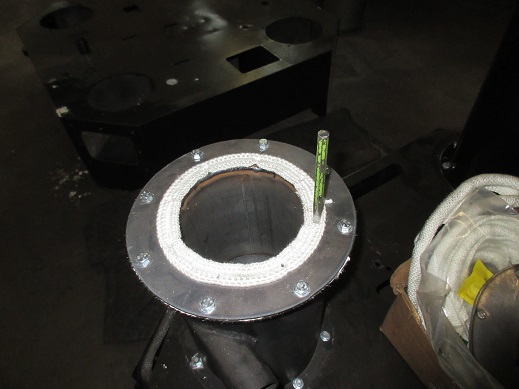

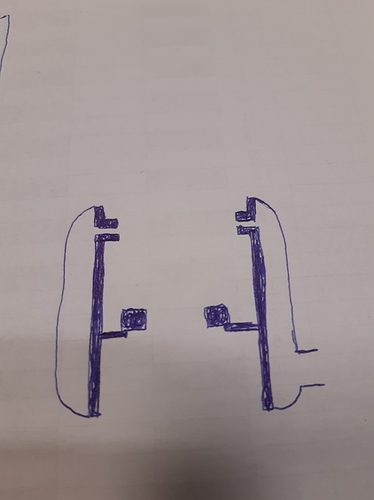

I will probably make a cheramic wool insulated reduction zone like this later when l get to it.

This gasifier run my Mercedes but just a few hoppers worth. Sof far so good but the real test will come now when l put it on my Škoda

reason being l wanted to make a hybrid gasifier that can run anything from raw wood to pure charcoal, but prefferably a mix of both.

reason being l wanted to make a hybrid gasifier that can run anything from raw wood to pure charcoal, but prefferably a mix of both.