Thanks Mr Steve, very constructive. I think Tone and me are after the same thing: a small gasifier to run a small generator.

I am thinking of the gasifier plans from Ben. He delivers cad files. Cut it out, weld, assemble and put it on fire. I don’t have time to shop for used material. Cut it from new plates and off you go, sorry.

JO had some interesting plan, could deliver some plates…

Hello All,

Winter slow time now. Time to deep think.

Tone I want to introduce a new approach system that I am trying to evolve.

Inputs + Outputs = fulfills Goals

So to work this Logic system would have to be expressed:

Goal to achieve = the sum of Inputs +/x the Outputs generated.

I have re-read and reviewed this whole topic again.

Except for JoepK.'s last post there is no pre-stated Goal/woodgas use.

To not have this then wood gasifier developing is:

Inputs + Outputs = Whatever occurs. ??? What? Blue flare gas? Woodgas as a further chemical input for molecules building? Woodgas to burn off for heating? Cooking? Direct combustion illumination? Woodgas for IC engine fuel powering?

And this approach without a fixed driving Goal is the Lab-rat/White-coat exploratory, inputs subsidized way. And the subsidizing supporters interests fades, they move on and leave.

If for direct IC engine fueling; then what is the working purpose for the IC engine?

Mobile different from stationary.

And size does matter.

Your recent posts on your home life with your long chunks wood chipping for your home heating gives many hints.

In this time of winter slowness thinking. Read here on the DOW of the different charcoal gasifiers working.

Approach a wood gasifier as a charcoal gasifer that makes all of it’s own charcoal internally.

Or not.

Kristijan’s more flexible hybrid fueled system has much merit.

And Joni systems do make blue flare clean gas and IC engine run.

So a challenge.

Is your Goal-to-be-achieved important enough to use someone else system.

Or is Made-By-Me the actual Goal.

Regards

Steve Unruh

I read this description that Til showed, and have a question.

http://www.gengas.nu/byggbeskrivningar/smp/kapitel_2.shtml

Why is the distance between the restrictor and the bottom of the fire tube reduced, according to the size of the restrictor?

I saw that @Joni, has a very small distance between the restriction and the bottom?

Hello colleagues,

today is the day that can really show whether your car is good on the wood. in the morning my thermometer read “-15C” and it made me think about whether I could start up and leave for work … Fortunately, my system did not let me down and I am already at work …

Let me remind you that I don’t use gasoline …

I think this was interesting, if it is true and I interpret it correctly.

It looks like the calorific value increases a bit if the wood is not really dry, I can understand this completely wrong as well.

Also looks like it would be better if the charcoal to go up on the outside of the firepipe, due to the insulation, that should be right?

http://runeberg.org/tektid/1945/0333.html

Jan,

The fact is that when wood (cellulose) burns, chemical water “Dulong water” is released and this water is enough for gasification of even absolutely dry wood. Proceeding from this, I dare to declare that any moisture in the wood only interferes with us and does not lead to the addition of the power of the wood gas generator. As far as charcoal is concerned, yes, the addition of moisture increases the hydrogen concentration in the gas produced, but everything is within reasonable limits.

Joni, I agree woodgas and cold temps seem to work very well together. It’s my experience cranking up on woodgas works even better than on gasoline when it’s really cold

My main problems are condensates. We’ve had a moderate -10C here lately, but I have only 15 km to work and it’s not enough to melt anything. I will have to make a longer trip really soon. BBB

What JO said .

No worry about my woodgas machines in cold weather . It is Wayne that is the problem

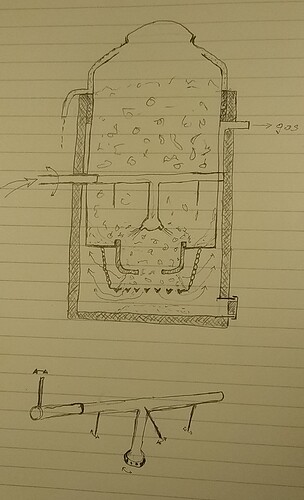

Thanks to everyone who shares their experience and knowledge, I tried to draw another sketch, a system with a center nozzle with side holes and the possibility of shaking. I intend to use the system as a stationary unit to drive cogeneration. What is your opinion?

Mr. Tone; I don’t know if you have read it before, but anyone who has and uses a gasifier, has said at sometime or another, “the secret to running a gasifier is 75% operator knowledge and 25% gasifier design and construction.” I suggest you take the most simple proven design (as much as any are proven for universal use) and construct it using the BEST of your talents. Then, go through learning as much of the 75% that can be learned, until you have reached a sufficient ability. And then, think about building something of your own design. I mean no disrespect. Just trying to point out the importance of the operator over the designer. TomC

I must say l agree with Tom here. It is good to start by making a good clasical lmbert first, to establish a baseline. Then, by trying out new ideas one at a time, make it better! Afterall, if you dont know how a “clasical” gasifier performs you can never know if your design works better, or worse…

I think l remember counting l built 11 gasifiers for my 3 woodgas cars and only now l am starting to get a feeling of how a good woodgas system looks like  and thats not counting the litle differences like hopper designs, coolers, filters etc…

and thats not counting the litle differences like hopper designs, coolers, filters etc…

Or even the material you put in it for fuel. BLM (black lumps mostly).

Is it possible to translate these texts in any easy way?

http://runeberg.org/tektid/1945/0826.html

Thanks Steve.

Did I understand correctly if I said that the important height is from the nozzles to the bottom of the fire tube?

The height of the restriction is not so critical?

I saw that under each page there is a text that works to translate with google, if anyone is interested in a Monerator from Finland.

http://runeberg.org/tektid/1945/0827.html

Good morning Mr. Steve and thanks much for referring to Jan’s article.

Below are a couple of short clips experimenting with moist fuel. Sorry there is no snow balls down here to test as was in the article.

Once Mike Larosa was visiting and I was showing out and did the same as in the below video . He dare not do the same and didn’t think the truck would run but I drove him about a 40 mile trip to the liquor store and it run like a top

Just because this water is going in the hopper doesn’t mean it is going through the motor .

You have to go 40 miles to get to a liquor store? For sure you aren’t in Michigan.

Yes Tom

At that time our town didn’t have a liquor store but the near by town did . That also where the jail is located

Sounds a lot like Grand Isle, VT where I grew up. We had a gas pump, but then they changed some law about the storage tank and took it out.

Rindert