Kinda like putting maple syrup and 90 proof in the same kind of brown bottle? Needs a different label though.

Okay, I have a bms for dummies question, I have 14 cells in series =48v I will have 14 of these in parallel. What bms do I need? Also I have 4cells in series=12v 2 of these in parallel bms? Thanks

Depends a bit on your cells and how they are wired. The BMS must be able to monitor each cell in each string. If you wire cells in a parallel arrangement before they are connected into strings, this makes them functionally into one cell (you could call them a Cell or a cell-group at this point for clarity).

In this simplified example, the top arrangement has 2 strings, each with 14 cells, so it would need a BMS with 28 cell taps.

In the lower example, you really only have 1 string, but each cell is now ganged into a pair. A BMS with only 14 cell taps could be used. The whole purpose of the BMS is to prevent the cells from drifting apart - since lithium cells that go too high or too low cause majors problems. With 2 cells physically connected, there is no way for them to drift, so you can monitor the whole group.

In your case, If it is possible to wire the cells as a parallel/series arrangement, then you could get away with a BMS with 14 and 12 taps respectively. If the cells are already in modules, then it becomes a lot more complicated, and you could in theory need up to 196 taps for 14 strings of 14 cells.

I dont really have much experience with what BMS options are out there - I have done a little research on EV BMS systems, but they tend to be pretty expensive, and probably have more features than are really needed for a stationary system. What is going to be charging the bank?

I tried putting 14 cells in parallel, they went dead in a few days. The ones I hooked in series have been holding steady for months. I want to use these for a solar system. these are the cells.

Were they being cycled when they failed, or did you simply build a battery and then a few days later find that it was discharged? Did any of the pouches swell? Did you check all the voltages before connecting them in parallel? If one of those 14 cells was bad to start with it could have drained the other 13, but I would have assumed it would have caught the whole lot of them on fire… Where did these cells come from? I have heard talk of QC reject batteries from China that get passed off as new stock, but I have never really shopped for this sort of battery. What is the chemistry, are they LiFePo4?

All were 3.6-3.7v, just built them never charged or discharged. I charged them back to 3.6v. So now I am going to hook in series, see how that goes without bms. Like the guy in the video said, you don’t know if they are working any how.

vanadium flow batteries

Yadlamalka Energy Trust has developed this A$20m project, featuring a 8MWh VFB with a 6MWp solar array, to produce low-cost and low-emission energy to the Australian grid, bringing approximately 10GWh of ‘dispatchable’ solar power every year.

Australia’s rapid rise in renewable energy in recent years has driven the need for investment in flexible energy storage technologies to manage the variable output from those generation sources. For this reason, the Yadlamalka Energy project, which is in line with the government’s Low Emissions Technology Statement, has been supported by the Australian Renewable Energy Agency (ARENA) with a A$5.7m grand.

ARENA’s CEO Darren Miller said: “The strong uptake of variable renewable energy has highlighted the need for increasing storage requirements and vanadium flow batteries could play a major role in addressing the emerging need for medium-duration storage, complementing the role of more established technologies such as pumped hydro energy storage and lithium-ion batteries in the Australian market.”

A revolutionary concept of all-organic flow batteries (ORFBs) based on water-soluble organic compounds was developed by our group to meet the requirements of large scale energy storage system, such as, robustness, low-cost, and environmental-friendliness

This is only true if you buy a BMS that does not have communication capability. The cheap little BMS boards that they use in stuff like power tool batteries are going to have that limitation. I am working on an EV conversion at the moment, and this is the BMS that I am going to use.

https://www.thunderstruck-ev.com/bms-controller.html

It communicates over CAN bus, and will allow a little readout on the dash to see high and low cell voltages, as well as other stats. Plugging in a laptop lets you get a whole host of information.

That would probably be overkill for what you are trying to do. I did hear about someone using a pretty simple voltage divider circuit that would light up an LED if either half of the string got too far out of balance - which would alert him to go and manually find the cell that was out of whack.

Some lithium chemistries are more prone to thermal runaway than others, but I would advise caution. It is the extremes of the SOC curve that is dangerous, so you can trade a little bit of capacity for a measure of safety. If the cells are well balanced to start with, and you are not trying to charge them to 100% with each cycle, you might get away with not running a BMS. Still, if you would be the least bit bummed if the structure you charge them in burned to the ground, I would suggest you get a good quality BMS  .

.

I bought a 4s BMS with blue tooth from https://batteryhookup.com been working well for a few months now hooked up to my phone simple readouts and parameter settings , other battery builders on my face book site buy the more expensive all singing dancing Daly from there on line shop 80A 100A 120A 18650 24V battery pack Samrt BMS LiFePO4 24V 8S Bluetooth USB device CAN NTC UART Batteries conn|Battery Accessories| - AliExpress

Just got to make sure you buy the BMS for your type of battery and decide on what amp size you need

Now, If you have 4 cells in series, 2 of these in parallel,=12v what bms do you need? These pouch cells are suppose to be safe from fire they just swell up. So they claim.

My charge controllers, and inverter can be adjusted so the batteries can be charged and discharged below, and above maximums.

This would protect a battery if it consisted of a single cell. Since you have a series string, however, the charge controller can still cause an overcharge.

Say you want to limit the cell voltage to 4.2 volts. So for a 4s battery, that is 16.8v. Now, imagine one cell winds up drifting, and it is .1v above all the rest. When that cell reaches 4.2, the other 3 will be at 4.1, and the overall voltage will only be 16.5v. The charger will keep charging, the high cell will go higher than is safe, and if it is the wrong chemistry, it will catch on fire.

If they are indeed LiFePo4 chemistry cells, then the fire danger is not really a problem, but the cells can still be damaged by overcharging.

for a simple 4s you could put something like this on there:

Or search amazon for a “BMS 4s” - there are a lot of options. Without a way to monitor the voltages, you will probably have to babysit it at first until you are convinced it is actually doing its job. Also, you will be stuck with whatever was programmed into the device unless you can find one that will take user inputs. The cells should have come with a sheet that specified the voltages that you would need the BMS to follow.

All this being said, good quality new cells really should not be that far out of balance, and they should not drift that much. Conversely, if you have bad cells to start with, a 15 dollar BMS will probably not be able to keep them balanced.

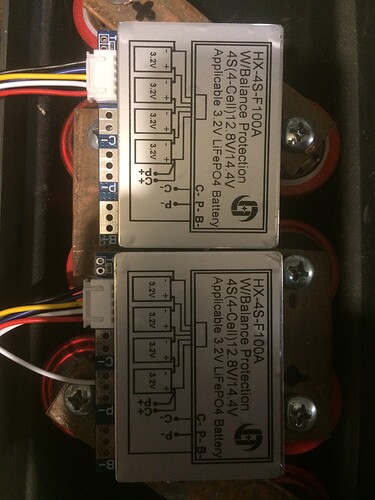

So do I need 2 of these? One for each series string?( this is a 12v battery I built from 8 headway cells) The pouch cells are lithium ion, I will have 14 groups of 14 in series, how many bms’s would I need? I have read and watched probably 50-60 videos and articles on bms no one addressees these questions, they take for granted everyone knows the lingo, and the application. thanks

Yes, if the strings are independent that is what you would need. There is no good reason that putting the cells in parallel should cause problems - but it does assume all the cells are good. If you draw a diagram of parallel cells, you will see that a single cell with a partial short will complete a circuit for all the rest in the parallel group. Generally batteries that use arrays of cells like that will fuse each one with a thin wire so that if a cell dies spectacularly it will not act as a dead-short for all the rest of the cells in that group.

A battery made up 14x 14s strings would need a total of 14 BMS, each one capable of monitoring 14 cells. This would be unwieldy at best. It would be much better to make cell-groups of 14 cells, and then connect those blocks in series to get your desired voltage (even better would have been to just have bought 14 cells that are 14 times bigger  ) But when you have a lot of small cells - this is the approach that is used.

) But when you have a lot of small cells - this is the approach that is used.

Bear in mind that if you get a BMS that is built to balance 18650 cells (with maybe 3ah of capacity), and you hook it up to a cell-group with 14x 8ah cells in it, it will be very slow to balance it because it will have to bleed off much more energy to drop the voltage of that group.

I hope some of this info is helpful. Lithium batteries are way superior to most other chemistries out there on just about every front - except for complexity, and maybe inherent safety

Hi Al what are these cells ? are they lipo ? lifepo4 ? what is the nominal voltage is each cell ?

did you buy them from battery hookup ?

If you look on here you will see there is a facebook page that will help with all aspects of building your own battery packs .

Dave

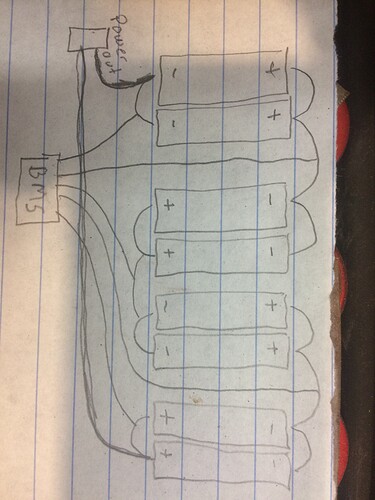

Can anyone help me with this.

Hey, I can not really see the bottoms of those cells, but I am scratching my head a little bit looking at how you have them wired… If you want 4s2p, I would connect them something like this:

The BMS taps could be connected with ring terminals to any bolt on each of the bus bars (Also, maybe give those (copper?) bars a light sanding  ? )

? )

As for wiring the load and charging current through the board, is it designed to protect the battery from overload or over/under voltage conditions maybe? Did it come with documentation? There is no way I would consider trying to push 100amps through that thing, unless those holes are a lot bigger than they look. You can look up ampacity charts for wiring, and the numbers tend to be a lot higher “for chassis wiring” as opposed to the power transmission values (like you would use wiring a house). How much current are you planning on drawing from this bank?

Also, it looks like those boards are designed for LiFePO4 cells, is that what you are using here?

Here is a good rundown on the most common chemistries and their specs: https://www.roypowusa.com/?page_id=37164

That will give you an idea of what sort of C rates you can shoot for too.

They look like headway LiFePO4 cells config 2p 4s , been told they have awesome power so be very carful with exposed busbars and as Carl mentioned clean the connections with some fine wet and dry paper , just a small amount of dirt can cause many issue’s .

If you can get this link to open up click the join button , these guys are very knowledgably and will always help out without talking down to you , not sure how many if any use the headway cells on here but well worth a visit even to read up on what people have built .

Dave