Thanks. I figured someone must have tried this and now I know why it isn’t a good idea.

I ran across this oil bath filter arrangement a while back and it seemed to make sense. I haven’t seen any designs of what folks here have tried. Are they similar to this or different. It’s hard to believe that soot could get through this design. Maybe the real problem may be tars getting carried through in the gas and doing the damage? If so, maybe we’re back to operating temps in the hearth. Just a thought as tars can’t be filtered out as I understand the process.

That is how a oil bath filter is designed but I sort of have to believe the people saying they tried it and it caused trouble. I know it works better then a paper filter with less drag on the motor hp wise for straight air you just have to keep an eye on them with tractors because they do use oil.

Again you fellows are overlooking the number one reason oil bath filtering is by far not very good for woodgas filtering: ALL WOODGAS IS WET GAS!

One of these tractor/truck/industrial AIR oil bath filter let get rain water in it turns it into a slimy, grey-gooy clogging mess.

I know. I’m old. Cut my early twenties teeth servicing these. Without the down turned rain cap. Maure-pit or pond sink that piece of equipment and it was hours disassembly, solvent washing, cleaning-up time.

And . . . what you gonna do with all of the soots/carbons contaminated oil, eh? Just dump it? Invest then in a whole 'nother centrifuge oil-cleaning operation?

There are reasons why all have evolved to either water washable filters; or a hot-dry shake out the soot-cake filtering.

Read, look widely why folks DO as they do. Shun idealism “perfect”, “better”, filtration for practical. Shun lay-about-cheap for purpose-made performance.

J-I-C Steve Unruh

Steve thanks for the info on the wet gas. I do know full well what you mean about the old oil bath filets getting water in them and the mess it makes. The entire reason I asked this question in the first place was to find out from those of you who had tried it why it didn’t work for wood gas. I do fully believe it when you guys tell me it didn’t work in this application.

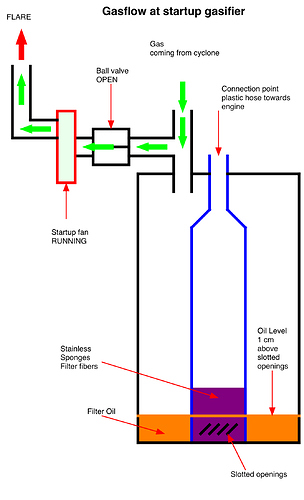

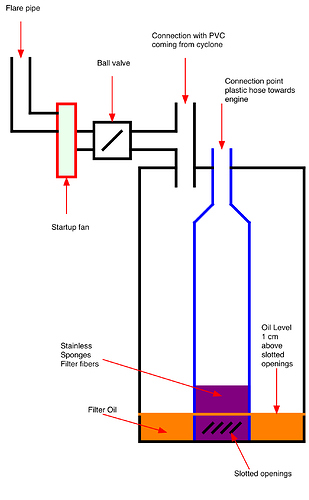

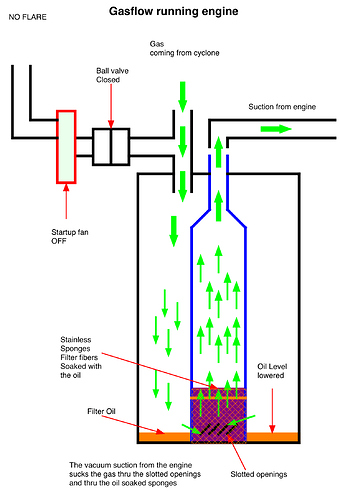

Oil bath filters, or at least the design i am using… ( the black plastic tank besides the gasifier )

The space above the oil i have filled that with a spread of chopsticks and bamboo fiber

In the blue tube the actual steel wool can / is higher then on the drawing

The whole set is also acting as a backflow prevention when i would use the flare

Thank you Koen for the filter plan … very inspiring!

How often should you change the oil?

Hi Thierry,

It depends on the dirt ofcourse, but i check and clean the stainless almost daily ( standard routine i want to teach )

The plastic drum has a drain plug and also a top level plug, to check the oil level, so i can top up the oil to the correct level easy. ( similar as the plug on a gearbox or axle )

Koen I see some of why you are willing to put the effort into making charcoal now. You have me considering building both charcoal and wood to experiment with around the farm.

I believe Koen is on the optimal track for reliability, ease of operation, weight, and system complexity. Others have pointed out quite correctly that the energy losses from burning off the hydrocarbons are arguably unacceptable, as was the conclusion of government regulators in northern Europe in WWII.

Koen is pursuing secondary chemical processes to recover some of those losses. In temperate zones though, I envision the perfect marriage - a stationary simplified gasifier designed to slip the char and burn any tar in a close coupled gas stream for heating and supplying hot water. If 5 cords of firewood are needed to heat a home here, then WAG, closer to 8 or 9 would be used if burning primarily the hydrocarbons.

That would result in a pile of charcoal sufficient for a lot of driving, or tractor work, hopefully even excess for biochar.

Regards,

Hi Garry,

Besides being it a less complex system to teach / maintain, all the filtering and cleansing setups are reduced to…

All the products from gasification can be used in one way or the other, depending the local circumstances.

Once you start to like the catalystic functioning of glowing charcoal, using it in a well balanced way, then you’l start wondering why they all forgot about the technology…

Some people are giving me the advice to use / build a gasifier to do raw bamboo…

Yes i can, yes i could… but could it ever been that easy as a Gary Gilmore Simple fire with charcoal ?

Your idea for the perfect marriage comes closest to my vision… Home heat stationary CHP, driving on electric or clean liquid fuel from the system…

The slipped char does a wonderful trick with air-pollution, water Treatment, adiabatic cooling / house humidity…

and at the end you can used it as fuel… feeding the ashes to the garden…

If i would live in a cold climate… i would know what to do, but would not have so much Bamboo

l was allso thinking about the heating stove/charcoal maker combo to produce motorfuel. l love the black gold. But l found now l can refuel my woodcar about anywhere on earth, if l run out of fuel. With charcoal, its a bit tougher…

I love the oil filter design. Any suggestions on dimensions or cross section area based on displacement? For cleaning do you just clean the steel wool daily and change the oil less frequently to keep down cost for fresh oil? Or do you change all of the oil every day and filter it for reuse? Are your slots made with a hacksaw blade?

Hi Bruce,

I did not use a pre defined sizing yet, just used what was on hand with in the back of my mind not to create an obstruction in the gasflow.

The slots are made with a 3mm cutting disc

The steel wool is rinsed daily with diesel, the oil only topped up when needed.

One of the “misleading facts” or “misconceptions”, if someone comes here for a show or presentation, is, that it looks so easy and always starts flawless, always have good power…

This is because i always clean the filters, always take care of good quality fuel and so on…

Most people are spoiled in long time maintenance interval’s and getting less aware of the needs for the engine.

Why would i build a huge filter if there is not a reason beyond having longer maintenance interval’s ?

My systems can run whole day full load and maintenance is done in the blink of an eye.

If the operator does not clean his filter before start, it will prevent easy start or good performance at the spot and he will know immediately.

Its all about habits…

I appreciate this good reply very much.

Your last two paragraphs are excellent explanations of what has been called “human-centered design.” A great reminder to give attention to the end user and the context in which the device/solution will be deployed.

Phapang design criteria is also a good advertising motto: “run whole day full load and maintenance is done in the blink of an eye.”

Thank you sharing your wisdom.

Hi Koen

With your oil bath filter, do you use other filters, cyclons, safety filters …?

Thierry

Hi Thierry,

On the pickup and Tuktuk, i only used the combined oilbath filter, a final safety filter could be a good idea, but i don’t have soot in my system so i don’t bother.

In the short run small engines, i just use foam

I can put any filter ( original paper, swimmingpool, or dirtbike filters) in line.

Its up to the machine i use and the purpose i am using said machine/engine

Since i never use the long term before maintenance schedule, it works just fine for me.

I really like this filter. it has a lot of advantages. It is compact, airtight valve, pressure relief valve, indicator of presence of water in the gas and probably low pressure drop … Have I forgotten something?

How about the temperature range? Looks easier to build than a bag filter.

No Thierry, you nailed it.

Yes Jeff, easy to build, easy to clean, and can be build for higher temperature if using some tin can materials.