The spark plug for the BGE head is RS17YX.

If you look at the shell electrode its completely covering the centre. On this engine ( Your BF ) it also has a ground strap electrode fully covering the centre as made by the factory. its tricky be careful but cut that ground back so it cover only half, and close up the gap to about .018. Wood gas is a little harder to ignite but its dry so this modification will help you get a little better spark if you find its got a miss. Many Onans ob NG or propane suffer from a light load miss and this trick helps.

This is a BF service manual for a tractor but the settings are near the same.

I will find a proper manual later. Aim for that .025 spark gap and hot running closer to the 25 DBT hot. A timing light will help.

With the BG head on the BF block the spark plug is more central located so its timing requirements are a little less

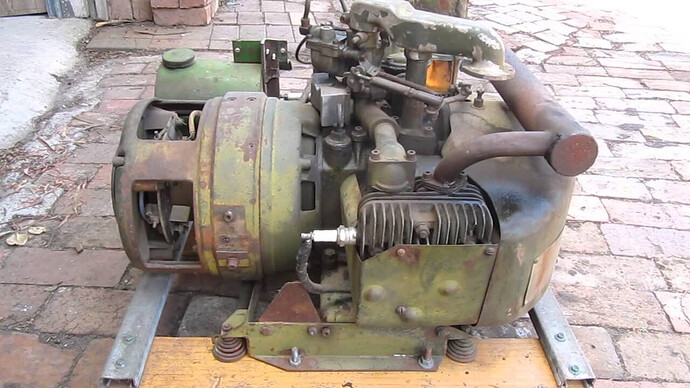

I had a hard time reading the data plate on the engine but I know its a BF so I know it has a conventional ignition. You could use an HEI modual from a GM car and Dual post ignition coil from a Subaru if you want/need a hotter ignition. Unlikely you will but if there is a miss you can not clear up thats a good modification. Use ther original point to fire the HEI for simplicity and if you have an ignition failure you can quickly switch back to conventional ignition.

A good read here with some tips by Brian Miller to improve the ignition on these flt heads

http://gardentractorpullingtips.com/ignition.htm

Again because I can not read the speck I have to guess, but this manual indicates that generator most likely has a dual voltage connection for the generator. BUT you probably just have it wired up for 120 volt and a factory installed Airpax 30 amp breaker on board.

I bet if you open up the connections you will see the M1 threw M4 wires to convert it to a 3 wire Eddison connection ( this can be done on a lot of BF and BG units, but cannot be done with any of the exciter cranked types that use a stationary field generator. )

The regulator on these is a transformer type. Not much to go wrong there just keep the sip rings clean with a Brillo pad if they get dark and dirty ( maybe once a year )

Page 50 shows a remote oil filter option for this you can add this part or improvise a remote filter, I strongly recommend this for wood gas just in case you get some dust sneaking past your filter.

ANY 9 bolt head gaskets fit this engine and they can be reused so its not critical to keep spares if you did or did not chose to make some copper ones.

You can buy copper high compression after market gaskets for the 10 bolt NH engine ( crazy people build airplane engines out of the NH, the same guys that make those can make them for the 9 bolt heads. Copper gaskets can be used over and over and over )

Added information:

I am reading up on the BF and I think I am confused about the generator end. I think it uses the same generator as the last production CCK square head. If that’s the case and it does use the exciter to start and has a stationary field then is is what its and the connections can not be changed.

Each generation of these after the CCK has been a slow evolution.They resemble each other very closely and Onan was very slow and deliberate not to make too many changes at once.

I need to try and read the spec number to find out.