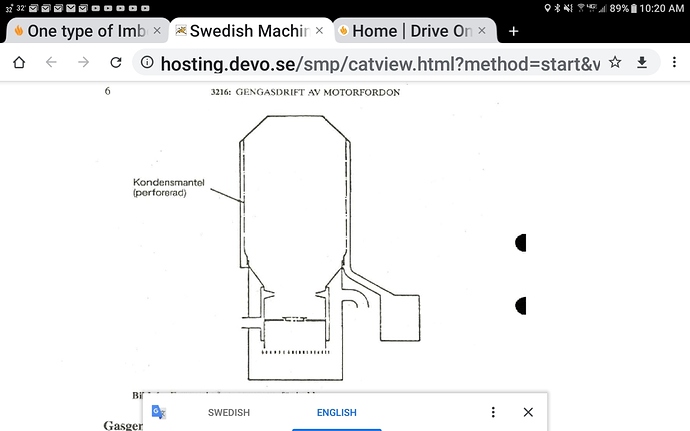

http://hosting.devo.se/smp/catview.html?method=start&viewMode=1&documentId=3216&pageNo=4

The last thing I found from Swedish machine testing, think it was done around 1985.

This looks very similar to a WK Gasifier if you move the gas out let to the other side and into a drop box with the incoming air going through a preheatexchanger then into the pre headed nozzle area. Just add some cooling tubes around the hopper. This design was very close to the WK but it was missing some of the most important inturnall and external parts. The WK is the first design of it’s kind that can handle different moisture types of wood and not so critical of wood sizes and types of wood, it can burn hard and soft wood. This is the beauty of the WK Gasifier vs. other wood gasifiers. The charcoal gasifier is another breed.

Bob

Hi, Jan!

31.12.2019

You seem to misinterpret what I described:

I am looking for a modification of the SPJ Keinänen’s monorator.

A modification I wrote myself some time ago.

This modification sends steam/humidity from just above the hearth to an outside the silo placed cooler with tubes.

The cooled gases return to the silo just above the silo funnel.

Nothing else is affected, besides that the wood just about to go into the hearth will be much drier than the wood at large in the silo.

Yes, and the rest of the wood in the silo does not get “condens-wet” at cool start-ups.

Max

Hi Max.

No, I just posted this link to show how I mean just having fiberglass fabric as a filter.

What you describe is something similar to what Wayne has on his generators?

Was it better than a Monerator, in terms of moisture?

Didn’t you buy fiberglass? If so, where did you get this?

http://hosting.devo.se/smp/catview.html?method=start&viewMode=1&documentId=635&pageNo=4

This link shows a little what a difference it is on different filters.

http://hosting.devo.se/smp/;jsessionid=3DBF5EEB866C6BA1AB94AAFE17D3F8FD.node0

There is quite a lot to read and interesting pictures.

Does anyone know what size of holes in a fabric it should be for gas cleaning?

I found this, where it says 200 mesh as a safety filter, then should the real filter have larger holes?

https://books.google.se/books?id=_zJHmz2EA3IC&pg=PA83&lpg=PA83&dq=filter+gengas&source=bl&ots=CvmohVb64y&sig=ACfU3U0N5kXqc09k5vISAvf8r-j3pYjoNA&hl=sv&sa=X&ved=2ahUKEwiZjriBs9_mAhWCpYsKHfl2BAk4ChDoATAAegQICRAB#v=onepage&q=filter%20gengas&f=false

Hi, Jan!

31.12.2019

If somebody wants to blast a “spark rain” into a textile filter, so be it!

Usually people use a cyclone to avoid that. No further comments on my behalf.

I am not describing something like WK .

I have earlier described a variation of the Monorator, which does not transfer the steam from above the hearth to the rest of the silo, but funnels it to an outside tube-cooler, which takes out condens and returns the dried return gases to the silo funnel.

Chris has worked on, and published a good essay on a balanced automixer for a 1:1 ratio Air/Gas.

Bob has continued to use it.

A Happy New Year to All!

Thanks for all intresting links!

Do think one could use a stainless mesh screen for hot filter instead for fiberglass?

Yes, it should work, it has been used before, thought to hear about price here, otherwise I may buy on e-bay.

Hi Jim!

31.12.2019

Yes! ALIBABA has very fine stainless & assid proof mesh at hand!

Very low microns!

It has been used by finnish ecomobilists, who have bought it on a bigger roll for a couple of users.

The freight cost gets proportionately lighter, when buying one bigger roll.

Still: Nobody blasts “glow-rain” on it! The composition will be destroyed by ANY glow treatment!

Ergo: This is no short way of discarding cyclones!!!

And, needless to say: A cyclone pot is fast and handy to empty,

while a filter cleaning may take whole a day!

Max

Jan, we use polyester needlefelt non woven for filtration of wooddust. 400 grams. I think it might do the job for woodgas, but like Max says , ideal for burning your filter. It can t stand heat and certainly no sparks.

Happy New Year , best wishes and hope to show you all something next year.

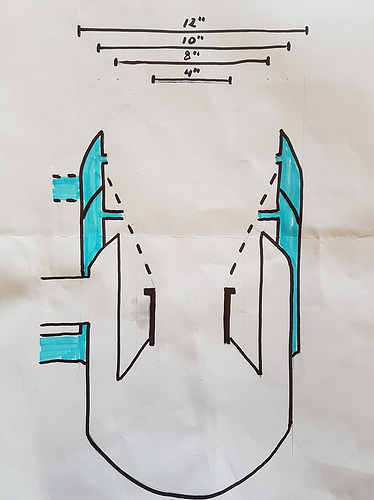

Thinking of imbert gasifier, does one have to have the cone under restriction, or does it still work?

Some use a cylindrical reduction tube which seems to be 1.5 times bigger in diameter then the restriction in most cases.

Using a even bigger diameter don’t seems to be problem either.

I think grateless types use same diameter as the restriction like JOs mazda and Kristijans chevy.

Hi, Jim!

31.1.2020

Yes, and heat-insulated expandable (non-buckling) swing-able bottom-plate!

(Instead of a conventional grate; the ash bunker remains as before)

Just outside the swing-able bottom-plate periphery you have vertical angle-irons welded to a screwed-on, hanging ring (screwed to the hearth bottom).

If you do not use a larger bottom-plate diameter than the restriction, you have difficulties to establish a vertical thyroid-circulation!!!

The thyroid circulation separates the “fly-ash” and aids the reduction char to work effectively!

Max

Happy new year from me at DOW, Max Gasman. I learn new designs watching your decribing gasifiers all the time. Caint wait too get around too trying your hot filter design, Thanks for the design decriptions.

Thanks, Kevin!

31.1.2020

Happy New Year to you too!

Max

No, there is no phisical cone. It naturaly forms when ash binds up over time. Its what we call a ashcone.

I mean the cone during the restrictions.

Jan, you’re right.

Kristijan, it’s about the upside down cone below restriction.

In the Rabbit gasifier I used a cylindrical reduction tube with a grate inside it.

I doubt the glowing coals notice much difference.

My suggestion is to just see to that the reduction is shielded off/insulated as much as possible. You want as little heat as possible to escape from where the magic happens - you don’t want the heart to heat the outgoing gas. A chubby pile of char is then preferable. But it’s a trade-off. You want some velocity too.

Is it over or below restriction that the gas is formed?