I started on a type of Imbert yesterday, now I got a problem.

As you can see, I have a slightly smaller diameter on the pipe to the bottom, where the outgoing gas should be.

The upper part where the incoming air enters has a larger diameter, and is quite long, which makes it go over the outgoing pipes almost the entire generator.

Will I take heat from the hearth if I do this? Should I short the upper tube you think?

That will not be a problem.

You will get some preheat from the gasoutlet and the heat taken from the hearth will go straight back to the nozzles so no heat will be lost.

It should help with the turn down ratio as the heat from the hearth will have more volyme has it store some in the intake and so it keep up the heat for a longer time.

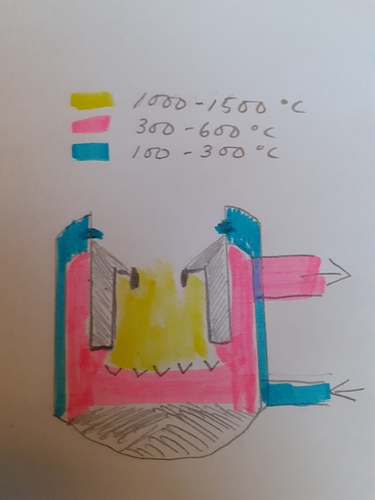

Jan, I would say stealing heat from the outgoing gas is perfectly ok. My drawing below is about what I did on the Rabbit gasifier (but not in scale). It did a very good job protecting the heat in the heart.

Look at approximate temps. Worth protecting is the yellow area. That’s why I went with a double walled reduction zone and the void filled with ash.

Edit: My Mazda gasifier has a less insulated reduction zone and the charbed cools down much faster. Enough heat is present high in the charbed for a good idle, but at a sudden acceleration it takes a while for the lower part to recover.

The way you did it is ideal in my eyes. I try to do d the same on myne. It is a good thing to cool the gas as fast as you can when it comes out of the grate, and with this setup you will do that plus preheat the air. Killing many birds with one stone. Allso, the allinall outer parts of the gasifier will be cooler.

Keep on the good work and dont forget to take pics!

Thanks for your answers, then I can start welding in the parts

( edit Problems with English)

Hello J-O and Jan!

9.12.2019

One additional suggestion: Make the gas-out tube screw-able, so you can raise off the air-heating mantel. It is also asking for bolting the air-mantel in the lower end, to the ash-pan…

Flangeing above the nozzles too!

As this seems to be an experimental developing build, avoid “definitive” welding seams on strategic places.

Max

Thanks for your advice Max.

Flanged over the nozzles, what does that mean?

Manteln sittande på en fläns ovanför munstyckena, antar jag.

With the hopper attached to the mantel it could then all be lifted off in one piece. Only downside I see, apart from getting things air tight, would be less heat robbing from the firetube’s nozzle area.

J-O !

10.12.2019

The snake eating its (heat) tail!

Max

Hi Max, it good hearing from you, I missed your informative input hear on the site.

Bob

Do you mean that I should protect the nozzles so that the heat does not eat them up?

Hello, Jan!

11.12.2019

No, I just “renamed” the re-circulation “loop” ; the allover leaking heat, and the mantel scooping it up and (re)delivering through the nozzles , to some benefit…

Protecting the nozzles happens mostly by keeping them hidden from direct intense radiation and glowing gas.

White-glowing char is somewhat counterparted by the internal airflow inside the nozzles.

I have earlier proposed to use a conical “balcony-ring” just above the nozzles, so NO glowing char comes in contact with the nozzle-tips or the nozzle-shafts.

This balcony-ring will also collect the returngases flowing out of the white-glow center and help the nozzle beams to inject these gases back into the glow-center.

In Tom Collins list it comes up in 635.

This is a “cut through” of the nozzle-area.

It was never built! Eaven as assisted with sheet bending instructions, but not.

Max

Ok, then I understand Thank you.

Should try to emulate the upper part of Käinen. so I don’t have to be so worried that the wood won’t be dry enough.

Think I’m welding the stuff together so I’m more sure to get it tight, the nozzles are in the nuts so, hopefully they can change.

Hi, Jan!

11.12.2019

Sektionsvis byggande är bättre i det långa loppet! Åtminstone för de yttre delarna, där luftläckage inte stör.

Section-wise building is preferable in the long run! At least for the outer parts where air leaks are of minor importance.

You might be able too change nosel if you use antiseize? though there is some higher temp stuff , caint remeber what it was called.

You are probably thinking of graphite or copper paste…

Max

Hi Max i bet that paiste is higher temp than anti sieze for threads.

Hi, Kevin!

21.12.2019

All the better! Used in hot places. Copper paste. Or graphite, if not burning off where oxygen + fire is present.

Copper paste tolerates oxygen.

Max

You can buy copper anti-seize paste in small plastic squeeze-packs at auto parts counters. Sold for spark plugs and such.

i order it by the tub online.