Thinking. This might be useful knowledge for those of us who want to increase compression ratio, and therefore power, and still keep the capability of using pump gas.

Rindert

So what I’m gathering from the video is, choke down on the air by using a smaller throttle? Would be interesting to see how well my little Holley 94 would help with bumped up compression in the 350.

If I understand it… choking the air/fuel mixture at the throttle body reduces the peak compression of the charge at TDC which prevents knock that might otherwise occur. If the fuel can handle higher pressures without pre detonation, no choke is needed and the full fuel-air charge can be delivered.

This is like the opposite of a supercharger which boosts the effective compression ratio. Here you run a compression ratio that too high (for some fuel) and adjust effective compression down by having the intake pull harder on the manifold and drawing more vacuum there than normal.

edit: was missing a “the”

That’s pretty good. I like to think of it in terms of cylinder pressure. A partly closed throttle makes lower cylinder pressure, and therefore stops engine knock.

Rindert

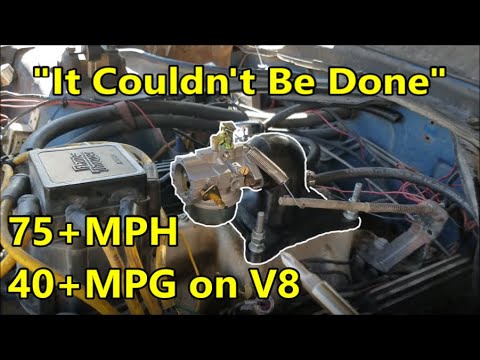

This also makes sense why Thunderhead289 could advance his timing so much with the lawnmower carbureted V8. He explained it very well with whiteboard drawings.

Skip ahead to 28:00 for his explanation.

Here in Europe we are “doomed” to use “small” wood gas diesel engines. Some time ago, I wrote a lot on this topic, where I also tried to explain the “controlled” method of damped charging with a gas mixer with a return spring, well, this is one of the possibilities, since it is impossible to regulate “damped” filling with a damper. Here we must be aware that in this way we reduce the capacity of the engine, because if the engine is filled with a pressure of 0.9 bar, this means 10% less volume of the combustible mixture… The optimal compression ratio of an engine that runs on wood gas is between 1: 11 to 1:13.

Hello colleagues!

Based on personal experience, I dare to say that when converting the same engine running on generator gas from a compression ratio of 9:1 to 11:1, the increase in power is quite noticeable. Another point with increasing the compression ratio that you should pay attention to is the advance of the ignition timing - it needs to be pushed back very much, otherwise the engine screams like a diesel.

Yes, there is still a problem with heating the engine in cold weather - it doesn’t heat up well even in summer.

Regarding intake restrictions (throttling), this will be a big problem when starting the engine in the morning, because the first outbreaks will take place when the cylinders are completely filled, which will lead to a “severe” shock load at a time when the lubrication system has not yet “woke up”. Therefore, I do not recommend exceeding a compression ratio of (theoretical) 12:1

Regarding the control of engine speed with a compression ratio that goes beyond what is allowed, there are also many surprises, the engine is very difficult to make it idle at about 800 rpm, it always wants to work at 2000. There are no choke and it cannot be stopped.

An addition which may alleviate this is a Moroso Accumulator. This aluminum cylinder, which contains a piston, has a ball valve at one end. Once plumbed in, additional motor oil is added. Intended for racing applications, in the event of a sudden drop in oil pressure, this device which is also under pressure, will provide an instantaneous supply of oil to the engine.

In our use case, closing the valve before shutting off the engine will keep three quarts of oil under pressure. Opening the valve before starting pre-oils the engine.