Put a value to what you are worth pr hour. Then go make fuel ready to run calculate your worth into that process. A 40 lb bag of pellets cost $4 to $5.5 this is 320,000 BTU pr bag. Thats a lot of energy for 5 bucks.

Char pellets should be around 9600 BTU pr lb. If you have a device to convert those pellets to charcoal and produce a means of primary heat in that process then you have a big win.

Pellet fuel energy density “”" by volume""" <<< key word there. it roughly three times as energy dense as chip fuel. Keep in mind chip fuel is going vary by species. I am comparing to cedar as this is the most common fuel we could get in my local to me area.

The issues with pellet fuel gasification is the combustion gases migrating into the hopper in a traditional down draft gasifier. If shut down the pellets will saturate with moisture and turn to mush. I accidently developed technology that prevents this. Yes this is my technology , it is mine and went through the sacrifices to develop it. It is my technology and Im not giving it away for free. Go spend your life savings, give up your house and develop your own technology. This is mine and I need to protect it. I did not get government hand outs, I dont have thirty employees like a competitor I have, oh no, I self funded 100% and I am the sole engineer here, nothing has ever been outsourced. Ive done what my larger counter part has done single handedly. Enough on that I could go on. However my view on direct raw fuel gasification has drastically changed since my earlier post here. As I have found that not even charcoal can be exempt from tar. Once this was revealed to me I immediately dropped my technology from market with 10 years of development and hundreds of thousands dollars backing it. That was not an easy thing do. Ive also found charcoal being no more difficult to produce than other fuels as the initial processing is much less; its more like creating firewood. Regardless if you burn it to produce charcoal or run a piece of equipment to produce fuels for raw fuel gasification, those processes require energy input. That chipper chunker also uses energy to run. Sure reducing fuel to charcoal is more energy used to create the fuel. So what!! If your time involved is less its worth the trade off and if you are not wasting that heat energy than you are not wasting it. In that scenario you are coming out way ahead.

Charcoal systems are simpler, charcoal runs way more stable, you can scrub this gas clean as NG, with a good water drip the gas is more powerful than direct raw fuel gasification, Plus that water drip is adding back energy for basically free. Just the H2 production from 1 liter of water is 15,000 btu, this is not factoring the Oxygen shift to Carbon = CO. I dont know how exactly to factor that as the charcoal is part of that equation. CHP systems are more viable with charcoal systems as you can get the heat in the charcoaling process for primary heat around the clock. Not the case with direct system generally the engine has to be running for the opportunity to reclaim that heat. Who wants to be running a system around the clock for both heat and Power. Not me, no way.

Im eating a lot of crow on some of these post;; I was very naïve ignorant, a bit arrogant and 100% hard headed. I am glad I have taken the path I had to take to get where I am today. It has not been an easy road getting here, not one bit of it. For 10 years this has been a struggle with hardship, especially the last 5 years in this market. I would not have learned the things I did trying to control and overcome the physics of a raw fuel gasifier plant. I am a pioneer there and am very proud of that. Programming in C logic was the last thing I ever thought I would ever be able to do. I had two choices when I want to tech school. One choice was programing and the other was mechanical engineering. Me? Program? no way that is way over my head!! and off to engineering school I went. I can now write very complex programing and am grateful to those that helped me along in that learning process. I love programing.

What is the properties of a good wood gasifier system? Well if your looking for both heat and power. I would be one that can produce primary heat, that can make fuel for itself and provide clean gas for power generation without fouling the engine. It would run reliably, and be simplistic. It would be viable and practical to use and not a chore to use.

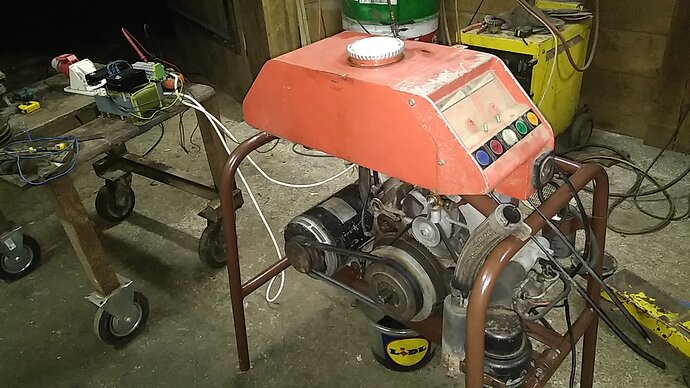

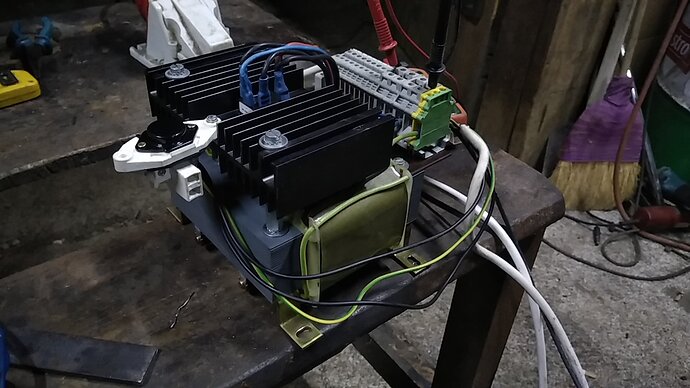

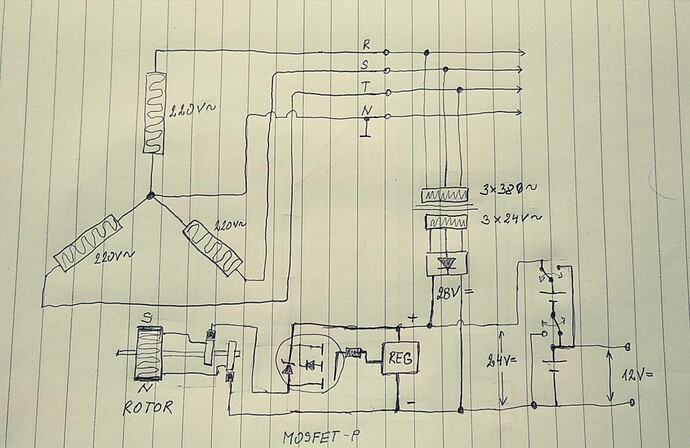

That is my vision now and what I just described is the VersiFire Power Stove. Indeed it does run on pellets, unfortunately the technology that makes this system possible can only run on a fuel like this. Other small dense fuel may work but in my development process we need to use something that is standard. Pellets fit the bill. We also have a pellet mill manufacturer we are working with. They will be our distro in Mexico, while we will become the distributor here in the US for their mills. We already make the M-1 Series and with innovative thinking you can turn just about anything into charcoal to run it. The way I see it, fuel that you can not process for raw fuel gasification is far more wasteful than the charcoaling process.

Those that maybe interested here is a link the VersiFire. I will launch manufacturing on prototypes this March and hope to conclude initial testing by May. June will take reservations for a short production run over the summer. These will be Beta units and we will test this platform in the field for probably a year. We will need investors to achieve all the certs we will need for this device and if all goes well we will be ready for 2023 model year production.