Sean , if you download the file from Eddy Ramos, the information you are looking for is, for example, for a flow of 5.5 l/s, the inlet pipe cross section is 1". As far as I can conclude from this data, the velocity of the gases through the inlet is about 11 m/s. This is a key piece of information for sizing.

thanks to all for specific cyclone informations, needs time for me to open all because of very bad internet connection in the moment

ciao giorgio

first foto the provisoric foam filter mad from a honey can…

second foto, filter housing from aluminium and stainless…

third foto, filter on the engine, note excenter position of rubber hose fixing, this allows mounting in different positions and closure frame with centered pressure…

first try, the coal was a bit humid and some water stands in the main filter and also in the foam filter on the bottom…there was no dust on the throttle…

with really dry coal a little bit of dust goes also through the foam…

the foam is from a visco-elastic bed materass…

the engine was good to start.

the dust on the foto was from some hours working

the last foto shows the under part of the foam filter

emergency welding…i have read somewhere that in ww2 times people made welding electrodes by themselves with chalk mantle around, but nothing more exact informations…

has someone heard about or made experiences?

ciao giorgio

Technically, you can weld with a bare rod. The coating, creates an inert gas layer to prevent oxidation, and also has a flux in it to remove oxidation.

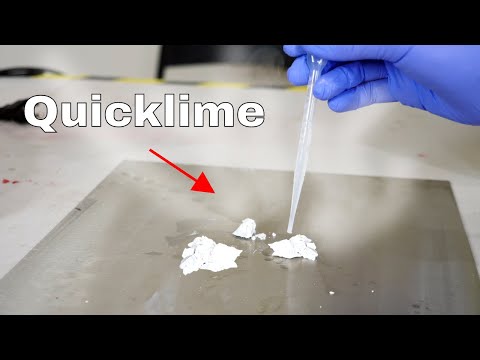

Chalk probably does work. Under heat it changes from calcium carbonate (chalk) to calcium oxide (quicklime) and releases CO2 in the process. And CO2 is commonly used as a shielding gas. I would guess as a flux, you could add borax, since they are both bases, and mix it into a paste or aqueous solution and coat them by covering, or dipping and drying like a candle.

Borax is used as a flux with pattern welding while forging, so I think it would work. A common household chemical too.

I remember an old blacksmith, that during blacksmith welding, he sprinkled the joint with brick dust, … he crushed a piece of roof brick with a hammer, … a mixture of clay and lime? Presumably this mixture could make good electrodes? Our chemist Kristjan would probably be able to explain this expertly.

I’m sure all that is right but I think I’ll just keep buying rod and vacuum sealing it. I’m going to have to research what was done when electric weld was first devised. I learned TIG welding in a motorcycle shop that built choppers. It was called heliarc then I guess because the shielding gas was helium. The welder was a large Linde machine. This was 1966. Amazing how much smaller and better welders are now.

Tone, first time l ever heared about brick dust. Many do however use silica sand.

I think a mix of chalk and borax is probably right on the money. But what to use as a binder?

My neighbour was specialized in aluminium brazing and told me they used to make their own brazing rods with diping alu wire in a slurry of some kind, borax based probably. Then leting them dry.

I think what l wuld try is thickly paint a slurry of 3 parts chalk one part borax on a peace of paper and try wraping that over the electrode. Making a kinda cigarette with a wire in the center.

I used to work in a shop where they made pressure vessels. We used a Submerged Arc machine similar to this. It was low cost. So I always thought; how can I use this in my garage? Can I coat that flux onto pieces of the wire? …

Rindert

the first coatings from the 1900s were clay or lime. Then 1907-1916, heavy coatings of carbonates and clays were used made by dipping then drying… Then later they added bits of iron.

I would lean towards clay as a binder given that is large group of hydrous aluminium silicates. the more modern industrial process instead of dipping, is extrusion. But it might be easier to cast them or roll it out and wrap it like Kristijan was saying.

It looks like they use kitty litter as the flux that goes between the arc and the metal, but it uses quite a few amps.

I felt smart for a minute when I downloaded the welding textbook, but it only goes to page 233 of 708, so I am only 1/3 as smart as I thought I was. ![]()

I did a job at GM Hydramatic back in the late 60’s Rindert. I watched them weld torque converters the same way. One right after another, flawless. No human welder can run that bead IMO. A while back a young guy here was showing his stacked dime Mig welds. I tried to explain about machine welds.

So Tom, Would you think a guy could make some sort of rig based on an existing mig machine that would allow him to do that? Would the head have to weave back and forth necessarily? Settings for current, wire feed, travel, weave width and freq, perhaps other parameters? A guy could just stand and watch and maybe turn down the current as he got near the end of the weld. Now my heads a buzzin. I just got to get my raw wood gasifier working.

Maybe this site https://buildyourcnc.com/ would be a resource.

Rindert

Rindert, it would do for a cnc plasma cutter. Forget milling, concept is way to light build. Look at the wheels and guidance and I wont mention the wood. Wood is for burning not building a cnc machine. Look at the finish of his product and the parameters he used. You can see the chainbumps and backlash. Lots of designs out there and I can give you one of you are interested.

I never understood what the flux was or why it didn’t interfere with the weld. As high tech as we ever got in the trade was oxy-acet motorized line burners. I have picked a lot of flux out of pockets in the weld in my time. Scratch awl and dental picks.

Short, yes, you could, and you don’t need it to weave necessarily. Here is a better desc of the technology from the welding textbook. I left in electroslag welding which is related.

pages148-169.pdf (6.2 MB)

Let me know if you want more, I can look in the AWS books. They are just too big of files to post. .

Wheew guys!!! I said I worked in a shop where they made pressure vessels. Read non cnc. But that sub arc machine made a lot of beautiful welds for us. Our welder guy had a foot pedal that controlled how a cylinder would roll or translate depending how he set it up. While I was there my main focus was on developing the capability to produce edge welded metal bellows. Imagine a tig welder built inside a lathe that was specially built for the purpose. No computer involved, but beautiful welds, yup.

Rindert

thanks for all the answers about electrode coatings…i am only a autodidact electrode welder with 3 batteries connected at 36 volt…never welded with other equipments like those what use protection gas…but a thought: would it be possible to weld with a rod or piece of iron wire and using our woodgas (burning) as shield gas??

ciao giorgio

Giorgio I don’t think it would shield. It has to be either Argon with some CO2 depending on the needs, or Helium.

People have converted Arc/Stick welders into TIG welders using a manual valve on the wand. But you would still need a tungsten electrode and the Argon gas.

Silica is used as a flux in metal refining to draw out and gather impurities.

Stands to reason what you say

Crushed glass, also Silica is another good flux in non ferrous metal refining from ancient times.