What would the reason be to use the water glass at all? I never use any on my WK gasifier. I thought it was just for gluing the ceramic wool to surfaces.

I never did anything to my ceramic wool in the fire tube except keep the poker rod away from it. So far so good.

It will harden it and help protect it, also keeps the wool from pulling apart and keeps you from breathing it in. Kristijan has noted it works great with rockwool and makes it more hardy to gasifier temps.

Perlite “pebbles” held together with some water glass is a cheap and firmer alternative for anyone worried about rock fiber. Rockwool is a better insulator (~4x better by thickness) and plenty cheap as well, but it does demand rigidizer for health/safety.

Hi Rindert, where did you explain how your “blower” grille works?

Errr. Grate blow off nozzle. That’s something that Tone Šuštarič came up with for his ‘Fergi’ tractor on the Tractor with gas? thread. LINK

Rindert

Yes, I know. Do you have a sketch or pictures of your nozzle grid construction?

thierry, how your air cooled nozzle works?

excuse , this was another topic…but i cannot find it now…

Hi Giorgio, you’re right, I’m not very good at keeping track of my projects.

As for the air-cooled nozzle, I don’t talk about it anymore because it’s always in the workshop and I never have time to work on it. I’m glad you’re interested in this project, and when I work on it again, I’ll let you know.

I’m working on that. I’m going to run the gasifier once more today. And if it goes the way I hope it will I’ll make a good, full scale, pencil drawing, have it scanned and post it here.

I made a bunch of layout sketches. I know what I was doing and thinking, but it’s just a mess if anyone else looks at it.

Rindert

Hello Rindert, I like your term “grill blowing nozzle”, you definitely have an interesting gasifier design that can work on a mixture of wood and charcoal. The “main focus” is created above between the three nozzles, which the gas flow pushes down towards the outlet openings, well, here you have an additional source of oxygen for burning fine charcoal mixed with ash, which loosens this content below and the gas flow carries the ash through the outlet openings without much resistance. The essence of this method is the ratio between the size of the air inlet openings, which ratio is right for your gasifier, you will find out during use. With Fergi, the ratio is about 1:15, the lower nozzle has a 6 mm inlet opening, into which I can push a wire and thus reduce the air flow, in the connection you can see the bent wire in the shape of a loop, but this muffled the air flow a little too much (interestingly, Mr. Don didn’t notice this either) ![]()

Interesting! I didn’t know you were restricting the airflow to the grate blow-off nozzle. @trigaux called it a grill blowing nozzle. I don’t know which is better. I think this is working very well because I haven’t had any problems with the char bed being restrictive. I am not sure that I need the little screw with the wire welded on it.

I have three main nozzles .227 inches (5.77mm) diameter. The main nozzles are arranged to create a vortex and they are angled slightly upward. Nozzles to restriction distance is 8.1 inches (206mm). Restriction is a simple piece of cast iron, ~3 pounds (1.5Kg), with a 1 inch (25mm) square hole. The first time I used it it bridged. After this, never.

This one makes little power when using pure charcoal. When I used 1/3 raw wood much more power. I will try it with more raw wood soon.

I didn’t know if it was going to work so I didn’t install a port to remove ashes. Today I began working on this. Tomorrow I will see what the ashes look like.

Also, I am making a better paper drawing.

Rindert

I took the ash pit off. Nothing seems bad. There is a lot of very fine black powder with some charcoal pieces. I am going to add it back into the gasifier, around the outer edge, so it will help build the ash cone.

I started the engine on gasoline. I started right up and didn’t do anything strange, so I think it does not have tar in it.

The filter I made out of a bucket and socks seems to be working well. So far I haven’t collected any condensate from this gasifier. I wonder if this means I can use wetter fuel? Or maybe I just need a better gas cooler?

Rindert

If I were you, I would try to insert a suitably large pipe that would hold the insulation with ash, while at the same time preventing the flow of tar gases (if you use wood) down the outer wall…

I will remember this if it makes tar.

Rindert

Making charcoal. 50 gallons of dry wood usually makes 35 gallons of charcoal. I use the TLUD (Top Lit Up Draft) method.

Rindert

I had to make a new air intake for the old Briggs. The old, very thin, sheet metal one just wouldn’t hold vacuum well enough to allow me to control the air and fuel mixture when running on woodgas.

Rindert

I put in an ash clean-out port.

I ran the generator for about 40 minutes. This time I used a little more raw wood, about 50% wood and 50% charcoal. I got a little more power. I’m waiting for two 15A Kill-A-Watt meters I ordered on Amazon.

Rindert

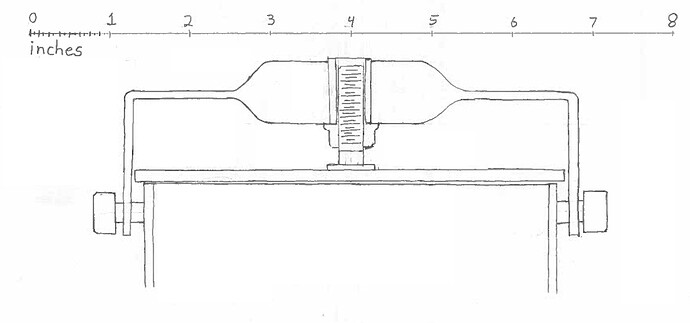

Here’s a drawing of the closure for the ash cleanout.