Looking at the charcoal retort, am I correct in thinking that the outer rings are made of concrete? Is it able to take the heat without cracking or wearing away? If it is concrete, what went into the mix besides Portland Cement and Sand?

hi Tom,

They did build copy’s from my earlier work based on the info found on my postings and with some guidance i give them.

Its imperative that they can improve themselves and that they get a profound understanding of what they are doing, not just copying but learning by doing.

Hi Ray,

i am not sure what kind of materials are been used, i just try to push their thinking towards a good end product, quality charcoal. In the progress they make, they also positivly are teaching me…

Amen! twenty times over

Koen , i have never seen a bunch of guys working with charcoal looking so clean and tidy !

That Bamboo charcoal has far less dust than our hardwoods we use here thats for sure , if only i could get my hands on Bamboo or coconut i may even be able to run my gasifier in a suit and tie

Dave

Good morning Koen .

Thanks much for the videos . Enjoyed them

Loved the videos. Really nice to see the common bond of peoples. Pepe

Koen, I am very curious what it looks like inside the 4" gasifier pipe?

(video 1)

Hi Billy,

Its a straight open pipe inside, about 120 cm long (48"), filled with charcoal, nozzle lit at the bottom/side

diameters of the pipe vary between 4 and 6"

Hi Koen , you mention nozzle on the bottom side , and i did notice a glow while it was running so i presume that the nozzles are horizontal on those builds have you made in roads with a decent material ? or are you using TIG type nozles in your small 4 and 6 inch dia pipe gasifiers ?

Dave

Hi Dave,

They build them with 15mm hole in the side ( like a small nipple female thread ) or just a hole with a nut welded on the outside.

Just to remember that simple also works…

All other options requires in depth thinking and add more to the difficulty level…

Whenever something goes wrong they ask my advice on how they can improve themselves…

I am actually surprised how fast things get picked up once they start doing by their own idea’s and how well some builds work…

As where i aim for highest power output, they are already happy when the engine runs and the pump pumps water…

Hi Koen , so let me get my head round this , you mean they just drill a hole in the side of the tube and weld a pipe nipple in and allow that to burn out ? if you have any close up pics that would be handy to look at and understand how they even manage a few hours run time .

Cheers

Makes perfect sense. no unusual materials. just weld in new pipe and pump,.Pretty soon they will; have found the perfect local material for making nozzles, the toughest ceramic or clay or metal part. It always works that way. After they replace it a few times they’ll start looking for an alternative. It will end up being Somethiing Koen will not have thought about. Unless he’s still available to ask what to do. Then they’ll just keep doing doing what he tells them. But still someone will figure it out…Poor People everywhere operate that way. They have some kind of survivability meter that is different than people that have too many options. And like Koen said, he’s looking for optimal performance, they’re just trying to make a pump run on charcoal.

This makes me smile. If you want something to spread, keep it simple.

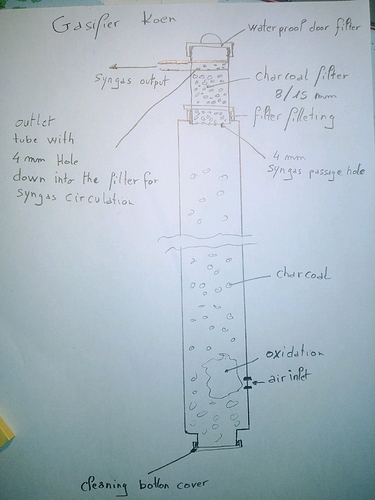

the charcoal gasifier Koen is a marvel of simplicity, but I propose the addition of a filter at its upper part with charcoal, for three advantages,

if the gasifier is used for a long time, there is a risk of significant dust rising,

more important syngas cooling is achieved

less fine particle in the filter before the engine. and after the gasifier.