Hi Steve,

Thank you for your concern about my motivation ![]()

I initially thought about having you rename the website DDIWBC (Don’t Drive In Woob But Charcoal), but ultimately I decided to learn more about charcoal.

Just kidding, of course. It’s true that a lot of information at once can be discouraging because it means more work.

I’m still happy with your feedback because I know what to expect.

I haven’t made a decision yet, and that’s precisely what makes it even more work. But rest assured, I don’t get discouraged easily.

Usually, I only have my own opinion on the questions I ask myself; more opinions inevitably lead to more questions.

Hello Kristijan,

Don’t worry, I’m not easily discouraged, and thankfully so, because I have absolutely no experience and I’m starting from scratch (even with the engine part).

And it’s been the same for all my projects.

When I became interested in the hydraulic turbine, I did my research without necessarily intending to install it myself, as it might have been too complicated or too expensive.

And it’s the same for the gasifier; I don’t need one, but I’d like to build one because it seems interesting for my purposes.

I’ve also seen other ready-made systems that are top-notch. But 40,000 euros was a bit pricey.

I’ve leaned towards gasifiers because it could be built for less.

I want to thank those who pointed me towards coal.

Now I have many questions:

Which method requires the least amount of work? Cutting wood into small pieces or blasting it in a kiln and then crumbling it after processing?

For the moment, I’m still thinking about it.

The more we discuss it, the more obvious it will become.

I understand that for you, coal is the best option, especially given your limited space in your vehicle.

But for me, it’s a stationary system, and I have plenty of space.

My options are less limited.

Whether it’s the budget for your 13 years or the available space.

The only thing I’d like to keep in mind is minimizing waste, because building 10 gasifiers and leaving them lying around the house isn’t my idea of fun.

David, 10 years ago I built my first gasifier. For various reasons I went for a wood gasifier straight away and put it on my dayily driver. The gasifier wasn’t perfect at all, but with a bit of luck I drove that setup over 20 000 km without making enough tar to ruin the engine.

As mentioned before, 75% of the road to success is about the operator. A few important points come to mind.

First of all, a wood gasifier always has to have a tall base of charcoal sitting on the grate - pieces no bigger than marbles. This will be your “tar protection filter”. It’s important that this base is kept glowing hot - keep the engine loaded. Whenever your gas shows signs of smoke, it tells you tary vapours escape the charcoal base - to coarse or not hot enough. 99% of the time this isn’t a problem and the charcoal base will replace itself as you go and will only have to be manually filled before your first ever lightup.

Since heat is a critical factor, you’re most likely to make tary gases when the gasifier is brand new. Over time the gasifier will insulate itself internally and keep the heat in better. To help this situation, it’s important to prefill voids with ash to start with. After a few hours of runtime and a dussin lightups and cooldowns, more dust and crust will settle and a broken in gasifier can take a lot of abuse.

Finally and maybe most importantly - fuel. No dust and debrie. Aim for egg sized chunks. Round 5cm chunks from limbs flow the best without bridging. And use as bone dry fuel as possible. Dragging vater vapour through the charbed and superheating the steam will only rob you of valuable heat. Wood chunks can never be too dry.

JO sayd it wery well. But has it realy been 10 years? Seems like yesterday when l first started following your thread…

“Which method requires the least amount of work? Cutting wood into small pieces or blasting it in a kiln and then crumbling it after processing?”

You asked a valid question here. And, like in many woodgas related things, the answer is “depends”.

I produce and sell BBQ charcoal. The finer stuff (we call Engine grade) is a unsellable byproduct. I use this.

JO has a lot of young growth and limbs wich his Rebak chunker transforms in to ideal round chunks.

Mr Wayne has sawmill waste that he chunks in a specific way that shatters the peaces but they hold together still.

Giorgio uses the twigs, wich he burns in bathtubs to make charcoal. A pain to transform raw twigs in good, string and dust free woodchips!

Steve’s wood supply are conifers. Good luck making good charcoal out of that! Wood gasification is his only real option.

Its up to you to figure out what works best for you, but for refference, you need about 1kg fuel for each kw of electricity. You do the math of how much furl prepp you got and how you are going to aproach it.

There are also gasifiers that can run on both charcoal and wood, or the best fuel in my opinion; mix of them both. If l were to build something like you are, l wuld aim for that kind of a sistem.

Hello Giorgio,

No, I don’t use them and it would be good not to waste them, but without too much work, I’m interested in an explanation of your fuel production process.

david, here is the topic, from first try to some developement…

as you wrote if you use your woodlands in a careful way,they can regrow and be reused and can least for you, it is also wise to use the twigs…and coal size for motor use is ideal without crunching…the fire makes the work and not some machines, and occassionally some barbecue with sausages and a good belgium beer

This debate between the merits of raw wood or charcoal always seems to spring up when a new member who is actually intent on learning about wood gas joins. That’s OK. It helps bring out a lot of information that members have learned making gas by both and even hybrid systems. Then there is the issue of mobile to stationary applications and fuel production. If you were planning to drive on wood then producing enough fuel to make that possible is a definite challenge. Fueling cubic inches rather than cubic centimeters is a whole different ball game. Making enough charcoal to power Wayne’s V-10 would be about a full time job. I get enough charcoal out of heating my house with a wood stove for 7 months of the year to fuel my 400CC generator when I feel like it. It’s designed as an back up system. Big difference. I have not yet built a gasifier that runs unattended. You may not yet be aware of types of gasifiers such as up-draft, down draft or cross draft. I really think you need to run a version of a Simple Fire, which is an up-draft, to learn the basics of wood gas. First gasifier I built was a down sized WK and I found that getting good CLEAN gas out of it was a constant struggle. The modifications I made to the WK design resulted in a tar maker which is the exact thing the WK was designed to overcome. I backed away from wood gas for five years because of that experience. Fiddling around for some years with simple up-drafts has taught me where my original built went wrong and I could certainly rebuild it to be a good producer now. Just not necessary for what I need out of wood gas now. I am not aware of anyone that has made a fill it and leave it for a day. The guys who drive keep their char beds open from bumping down the road. I think Dave in Australia can run his up-draft for about 4 hours unattended. I run mine while I’m doing other things outside and have to occasionally adjust the amount of air to compensate for changes in the fire zone. I can tell by the sound of the engine if the mixture need adjustment. Others may do better. I am not the most proficient operator here by far. Anyway, for all these words the point comes down to the necessity of learning by doing and not just reading.

Jan,

Thank you for posting that link! There are many gems there, and my Microsoft Edge browser will translate the text. I even found web pages with period photographs I have not seen before! ![]()

Great, thanks Jo.

So, branches the size of an ostrich egg are okay too? No, I’m just kidding. 5cm logs are perfect; I already have some dry ones, I’ll just need to cut them to length.

I’ll put the larger ones in the boiler and the smaller ones in the gasifier.

I’d like to benefit from your experience, if I can? Has your gasifier evolved since then?

I don’t know much about dry wood and its moisture content. As you can see, my wood is stored outside and covered, but it’s sometimes battered by rain during strong winds. Does that have a significant impact or not?

Thank you

Good morning DavidP.

Let me help you navigate through the rough DOW surf for some of the informations you seek.

The best informations are the experiences of members who have actually built and power loaded operated.

The top of page tool bar tools of search (the magnifying glass) and sub-division categories listings (the stacked papers icon) helps. But still too much just cannot be found.

For the individual members builds and experiences you can simply hover over and click open on thier avatar thumbnail.

This opens a small information window on them.

Click open again on their avatar picture there, or round letter icon.

Opens up a more expanded listing of their whole DOW activities.

Read, scroll through their started topics.

In my post to you on this topic I put up intentionally highlighted action links to some members. A short cut for you to the same place.

Here are two more guys who have done successful home power woodgas build up USING RAW WOOD:

@docdcox Danny Cox, SE USA. He used a commercially made Ford four cylinder electrical generator.

@Yukon_Trapper Brian Guage, Yukon Canada built up a Ben Peterson book system for his home electricty.

I can keep going back and putting up these successful turn-my-RAWwood into my home electrical power all day.

Steve Unruh

Kristijan, I like your way of thinking; the solution is a gasifier that does both… or a system that can be bypassed. Thank you, it’s very inspiring.

Hi Tom, I understand your point of view.

For me, it will be a stationary system, but as a backup, since it’s to produce electricity when my other systems aren’t.

From what I understand, small wood gas systems prevent efficient wood burning.

Since I have batteries, it might be more sensible to produce 10kW and store it for 3 hours rather than 5kW for 6 hours. Would a minimum of 1.5 hours help avoid certain problems?

And the system would run for 3 hours every two days, for example. I’d prefer not to have to monitor it… I’m not retired yet (a little teasing for those who are).

Thanks

Great, thanks Steve, this information is valuable

I think a lot of Nederlands people are like that. You will never have perfect information. I had to learn too. Someone told me a term ‘analysis paralysis’. It helped me. I think you should listen to Kristijan, and make a SimpleFire from a 20L bucket. Success!

Rindert

Thanks Giorgio, for the link and for the beer reference

The SimpleFire, a seal with 2 holes? I suppose its purpose, in my case, is to make the necessary adaptations to run the engine?

Tkanks

David, I’m in a similar circumstance as you, building an off-grid house with solar and batteries, and woodgas for a backup. I’m going to recommend long-term that you build either the Ben Peterson gasifier, or the Wayne Keith gasifier, sized for a 3 or 4 liter engine, similar size to a truck. Run the generator, make enough power to recharge quickly, then shut down the gasifier. One or two hopper loads should get you through a cloudy day. Do not plan to run the generator continuously, the gasifier will get clogged, and you should plan downtime to clean out ashes, etc. 4-6 hours and then shut it down.

My personal plan is to convert a gasoline tractor to woodgas, then use that to run a PTO generator. Then when I don’t need batteries charged the tractor can be used elsewhere. In the USA, we have an abundance of old gas tractors that nobody wants.

As far as the charcoal, I have no opinion either way. It could be a useful tool to learn. But making charcoal is a process on its own that you will need to master, and you will lose at least 50% of the fuel value making it. If you have a use for the heat, OK. If it’s just temporary to learn about woodgas, OK. If you are ready to dive in 100%, I think I would just build the wood gasifier and learn to operate it. We can help with that.

Yes DavidP. 2-4 hours a day; twice a day are the batch production cycles that has made the most difference for the sucessful wood-for-electricty for the daily needs folks.

A larger system. Brought up quick to operation and kept at efficient operation. As much of the total energy released direct used as in daily scheduled laundry; family showering; large meals cooking. And as much as possible the rest stored as thermal and chemical. Your capabilities.

So a large multi-cylinder internal combustion engine. 1000cc minimum to a larger four cylinder.

To get a raw wood system to self feed for 2-4 hours; wood drying and best chunk sizing will be critical. Longer than 4 hour and the “make the hopper as large as you like” approach, will bite you in the ass at last four different ways.

Not so hard getting the just-in-time dried down, and even pre-warmed wood IF you put the will make reject “waste” heats from all of the systems in a dedicated small enclosure. Not under your house. Not attached to your house.

And when no longer producing gas and therefore power; all of these heated lumps will be bleeding off mass heats. Get creative and put these always wasted to the crows heats to work pre-drying down as-cut; as-picked up future fuel woods. Drying down wood is actually an energy storage in the future usage. You are conserving the woods combusted relased enrgy.

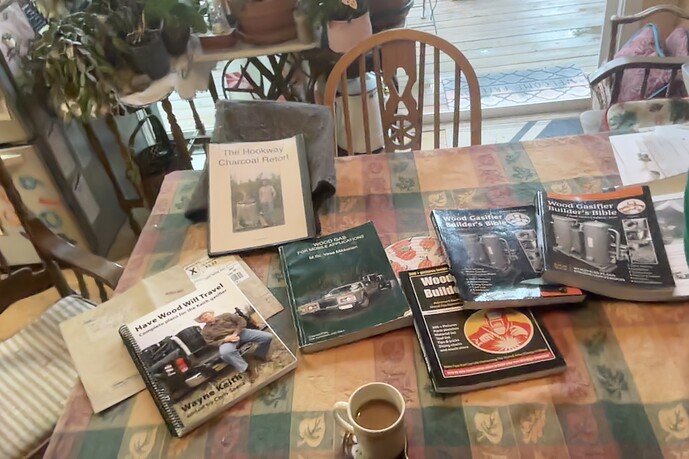

In sixteen years, of thousand of hours pursuing this I have only found and retained four publications and books that a fellow can actually build from:

The authors have done much in their books to explain needed-practices of operations.

Enlarge the picture and you can read the titles/authors and Net look up how to buy these.

Vesa Mikkononen’s book has detailed blueprints for four different sized, and purposes wood gasifiers. He says his for four cylinder engines system is the one to use for home electrical generators. Still an expensive, complex build.

Wayne Kieth’s system you’d commute vehicle travel then once home fuel your stationary generator for your 2-4 hours. Not a quick and easy system to build. But the one best able to handle really, really wet wood in humid conditions.

Ben Petersons book system is the more reasonable one to build up and use. He designed and sold for years much more elaborate, complex systems for sale. His book system simplified for building from common tanks. The same base information in all of the three series of books. But each version with expanded out step details for the askers; and more fueling preping information. Automation for the mixer control added in the 2020 version. His in the trunk charcoal Mustang stealth car only in the 2017 version.

Expect some here will trash me as “selling” “shilling” for BenP. about his books.

He; like Dutch John has wearied of the forums social turmoils.

Neither really wanting to be contacted and exposed anymore to the abuses. And in BenP’s case - the intellectual property thefts.

Fight the surf; sure. For the best fish; crawfish; clams and mussels. But know when to leave for the more peace of inland, and the offshore. The surf is a rough and dangerous place to be.

Regards

Steve Unruh

Hi Chris, Great, don’t forget to build two and send one to me by mail…

According to the AI, Ben Peterson’s system is designed for smaller pieces of wood than Wayne Keith’s version. Is that correct?

Isn’t Ben Peterson’s more complex to build?

Thanks for the advice.

Nice project, might as well use the equipment for multiple applications.

I also think all that wasted heat is a waste, but for twigs, it’s better to burn them in a bathtub than on a pile. But isn’t burning wood shavings just as efficient?

Steve, thank you for these explanations, always very helpful.

I’d like to use this wasted heat to partially heat the house with a water chiller and a circulator if possible…

Producing electricity is good, but wasting heat it is bad!

It’s true that this method is certainly more complex than an air chiller, but I think it’s worth it.

Drying the wood is just a matter of time and space, and I don’t have too much of a problem with space, I can stock up.

I’m not ruling out the idea of drying some potential wood chip, though, since the shredded branches will be green.

What a coincidence, I’ve already added two of his books to my Amazon cart.

Thank you for confirming that VesaM’s book is less suitable for me; that’s what the AI told me.

I don’t doubt that the book is interesting, but with my basic English, it takes me longer to translate the printed version.

My plan is to combine the BenP and WK systems, as each has its advantages and disadvantages for my use.

It’s probably presumptuous of me, but I think I can manage it because each part is more or less independent.

Then you have to find the desire and the will to succeed.