enamel finish would prevent erosion pin hole of gasifier

Ha,ha, Joni even in your country you are referring the gasifer in the female from. Yup,

You understand Gasifers.

Bob.

Hello,

this is a cross cut of the WISCO-gasifier Joni is referring to:

Just scroll down a bit. Truly a clever and compact design.

It is the web page and car of Daniel Hagen in Switzerland. Many of you should know him.

Excellent Til.

The sites to-English-text is near 100%.

Pictures shows his added grate motor actuator. He refers to an added system on-demand shaker.

The YouTube video lower down watched on YouTube CC/translates to English ~90%. And he explains his “bet” long time in winning. Clearly states he kept this duel-fuel gasoline.

S.U.

Thanks Tel. I thought I recognized the Opel when I saw the back bu,mper he made. I have been envious of that car since I saw the first report. And then he came out with that ‘‘cherry’’ Model A. TomC

…

Okay I got things on the right thread this time, sorry Joni it is late here and I was commenting about your gasifer but I wanted on my thread.

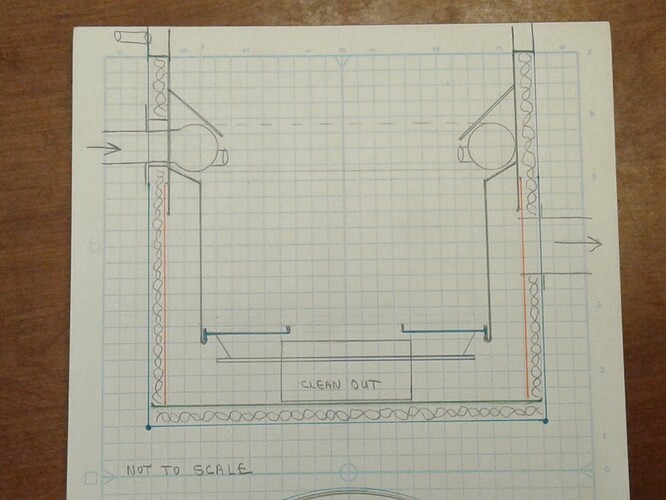

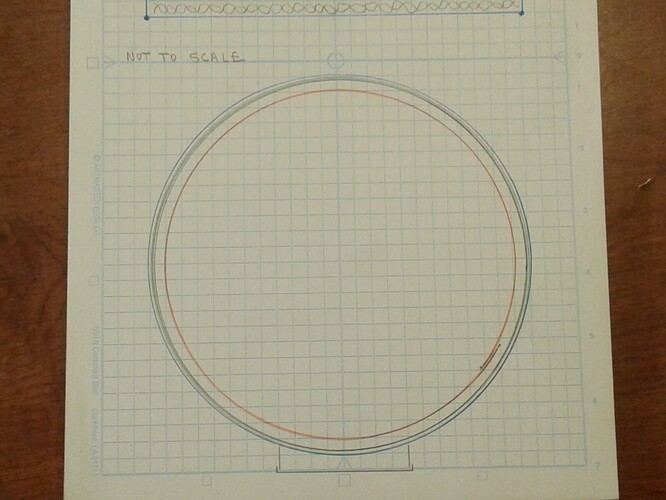

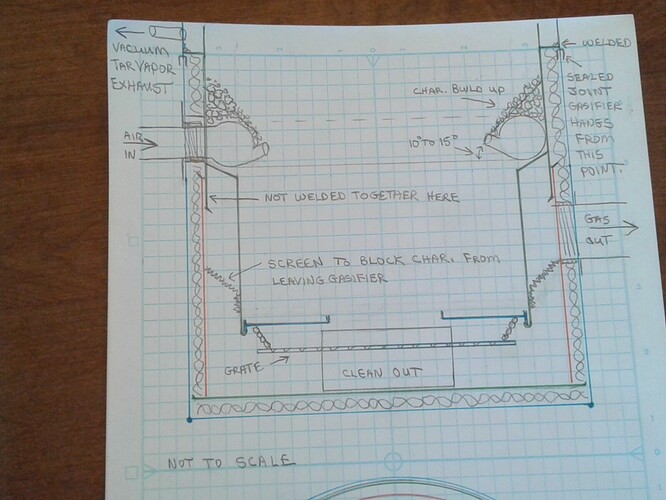

The Barrel in a Barrel in a Barrel has change thanks to Joni and other members you know who you are. The problem I have is I want to build everything way to heavy so the only way I can build a light weight gasifer is to copy a proven design that will work on my Subrau Outback. The drawings above is what I think mite work. As always your input is always welcome, I like constructive criticism and you can hurt my feels because I have alright be wrong on this build from the starting of the first drawings. Lol

You just got to love it.

Bob

Bobmac,

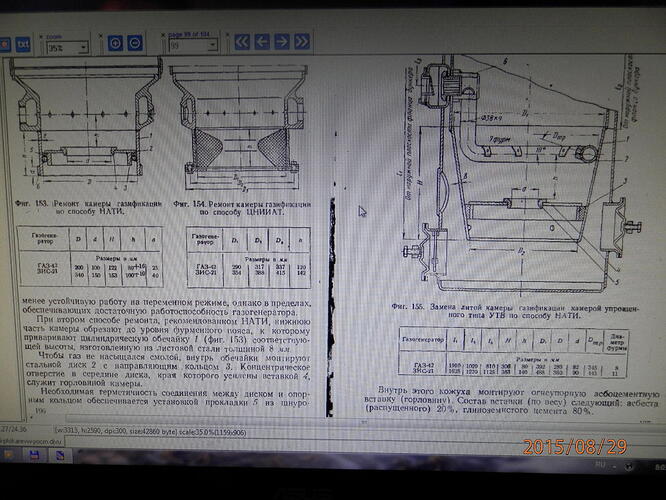

all this is good, but you need to raise the tuyeres upwards by about 10-15 degrees, and you do not need an “umbrella” above the air supply ring, it will be made with coal … You need to be guided by this picture.

That gas generator (with air supply through a pipe is designed for a 5.5 liter engine but with a low compression ratio (6: 1). And one more thing, I would make a grill. The tables show the dimensions for engines 3.25 and 5.5 liters.

What is that business where the pipe to the nozzle ring feeds through the shell. I wish I could expand this view.

It is an assembly joint TomH. You are seeing a threaded ring-collar.

S.U.

Thank you Joni, for helping me. Okay the picture diagram is great I will try to keep it light weight and follow the instructions in the picture.

Bob

What about useing the first barrel next too hopper as a cooler, And that looks like your plan is a hopper cooler? and then the hopper condensat tubes like WK THROUGH the hopper cooler barrel, It would add heat too incomeing air, then run the air through the other heat exchangers, before entering the hearth, NOT THAT ITS THE ONLY WAY ROUGHT THE GAS,just a posible path . I like the idea of cooling the hopper if it helps rid the condensate, as it would make for a cooler hopper serounding area.?

Hey BobMac,

Here is a link for dimensional possibilities. Don’t go having a heart attack over their prices.

Diligence can fine these used out of the dairying, pickled foods, and wine industries.

Danny Cox; BenP, and J.O. getting their SS stuff out of the paper making industries.

Click open each one on “View Details” → “Product Specifications” for the dimensional specs.

S.U.

Now not going back to your original B in B in B concept looking up the dimensions 85 gallon down to 20 gallon in four steps you will see that these will all nest stack.

In one inch size gapped increments.

And that’s a bit tight for a gas flowing area. Doable IF you do not let soots build up. Another reason to narrow slim down the inner below the nozzles areas. Give gas and ash collection space.

Then the stacked weights for the four would be 82 + 50 + 35 + 20 pounds for roughly 187 pounds. Then plus shelving, passage connectors, air nozzles, external mounting brackets, and such; be 2X that for at least a 350 pounds of hearth/hopper, BEFORE cooling and filtering.

Too heavy for your rear Subaru.

Would have been too big, and expensive for my small electrical generator systems.

Anyhow now back to your current.

Pick say two of the 30 gallons for your outer jacketing housing base starts.

And two of the 20 gallons as your innards shell base starts.

And two of the 20 gallon ones as your filter/condenser can.

Then with your outer dimensions fixed; do your Joni-in-a-can emulation.

S.U.

Opps. I forgot.

35+35 + 4x20 = 15O pounds base starting weight, now including the filter.

Hey BobMac,

Maybe I’d best clarify my early-on interests in doing a four layer; barrel in barrel.

This was back in 2008/09. I’d been as much as possible studying the most modern Finn all SS systems.

They use four “shell” (walls) systems.

Their internal air and gas flows is in a modified “W” pathways.

Super, super air preheating. Very hard to fabricate and keep air and gas separated tight. And remain tight with system use heating’s and contractions.

Resulting in systems that have results that can be gotten in other ways.

Joni’s GJ 7.0, 8.0 and 9.0 as the simplest, lightest shown useable so far.

VesaM’s system plan for a vehicle your Subaru size would be his proclaimed gasifer “Small”.

" . . .for European and Japanese passenger cars having engine cylinder displacement from 2 - 3 liters displacement and with engine power output on petrol from 90-130 kW"

His small system is 166.5 kg (375 pounds).

Why he trailer mounts. Adding more weight to drag around.

S.U.

I agree with Steeve on the weight, since it is nearly imposible too get a best system build for non stationary. maybe the WK COOLER TUBES use aluminum and hose clamp on, wood need one less barrel, and work well,easy too clean, and easy too repair any cracking on first two barrels.?? first two barrels as hopper cooler and start of heat exchangeing rought.?Thats what i may build next when i make time. Enjoy your welding practice fabrication. I need some caps or diodes for my mig before i like welding.

Yes on the WK cooler tube system Kevin.

All other systems either use a upper only condensate collection gutter.

Or only a lower hopper gutter system condensate.

ONLY the WK I’ve seen to use both! Connected by the cooler tubes.

Bob you now know this system well now.

S.U.

Yes Steve and Kevin, my hopper unit collects lots of water and tar in the condensation tank. I have 6 cooling tubes on the out side of the hopper with fins on all 6 of the tubes.

I am curious if I hook up the Vacuum exhaust tube system to my exhaust pipe how it would change at the condensation tank in water or tar.

Bob

You are right Steve, Joni’s gasifer has everyone beat, simple and light weight and can run a vehicle 100% on wood with no gasoline. I will be making my own modifications like the hopper will come off of the lower gutter and the low gutter and the rest of the gasifer firetube, and grate will be able to come out of the ash barrel clean out.

Why so I can make modifications to it.

You know me I like to keep working on my Gasifer even when it is finished and running.

I can actually see four barrels still in my design. 1. The hopper barrel, 2. from gutter to the grate another barrel. 3. And from the gutter to the outside bottom of the gasifer the barrel. 4. If you count the heat shield in the bottom part of the barrel that makes four.

Bob