Hi Nathaniel

please excuse me to use your topic . But I really like your search

I built this autoclave, it is not a “riche” but has some points in common with a riche

Thierry

Hi Nathaniel

please excuse me to use your topic . But I really like your search

I built this autoclave, it is not a “riche” but has some points in common with a riche

Thierry

It distills the wood, like the Riche’, but I think what makes the Riche’ unique to other distillation retorts is the tar cracking red hot charcoal zone. I think it is that ability that makes it so potentially useful. But that’s just me.

Someone that wants bio oil, or pine tar, or anything else, might want a different setup. Like yours seems to save the liquids, and use the gasses to keep it running. What are your plans for the liquids? Have you considered starting a thread in the science category, or maybe the charcoal category, about distillation products? Maybe asking what others have done?

I would like to use the wood vinegar (pyrolytic liquid separated from the tar by decantation) in drop in the nozzle of my carbon gasifier (to control the temperature of the reaction and enrich the gas)

plant tar has a lot of property (antiseptic, wood protection …)

My comment on this link explains why I try to colect Wood Vinegar. It´s something to tke in account. I think

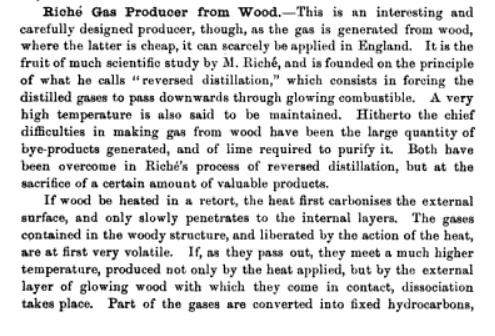

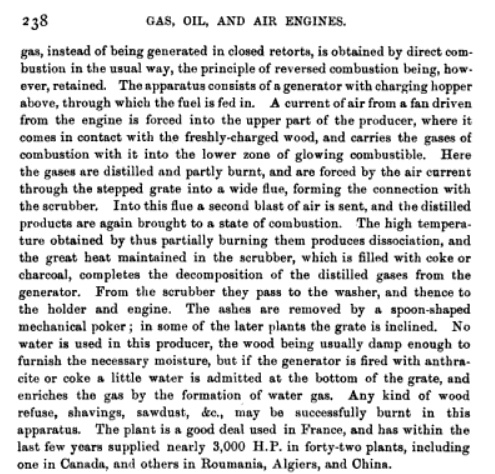

From: A Treatise on Producer-gas and Gas-producers by Samuel S. Wyer.

Hi Nathaniel,

i enjoy that people do read the “old” books and learn from that

I have a older thread with a link to my library on google drive. Feel free to look around in them.

btw, your book is in it to

Do not forget the Guénot gasifier, which is much smaller than the rich but also powerful in distillation in a retort.

Just realized, I cut off a good chunk of the bottom of two pages from A Textbook on Gas, Oil, and Air Engines. Sorry about that. Here’s the whole thing again.

And thank you Francois and Koen for sharing what you have!

Here is a (overly) simplified sketch to help illustrate what I think is the main principal of this design.

Disclaimer: It looks like Riche’ was a tinkerer, like many of us. There seems to be multiple iterations of his gasifier. This sketch is just to highlight some of the more interesting principals.

I first learned about the Riche’ from a book How to Convert Wood into Charcoal & Electricity by Richard H. Buxton (I miss Lindsay Publications). But he fails to mention the cherry red reduction zone in his book. Seems he missed that idea because he mentions having a lot of issues with tar gumming up his engine. I missed it myself the first time I read through one of the old books. It is the heart of Riche’s designs.

Not every retort has to be a reducing (red hot char) retort. Multiple standard retorts could feed the reducer. The ten inch diameter suggested in the books probably only applies to the reduction retort just to ensure that the reduction zone is turning cherry red all the way to the center. The distilling retorts could theoretically be any size or shape you want, as long as the reducing retort could handle the gas flow.

Fresh fuel (wood, switch grass, etc.) could be put directly in the reducing retort, which would probably increase gas production. Or charcoal could be put in from the distilling retort, and the reducing retort would just be used to crack the tars. Used in that configuration, I don’t think the charcoal would be emptied from the reducer. A small amount would be consumed in the reduction process, and the retort would just need topped off from time to time.

The description states that the cast iron didn’t last long, which makes sense. That was pre stainless steel time, the right grade of stainless will probably work much better in that application. Either that, or make a flanged disposable section subject to the extreme heat…

One book mentions a retort life of 8 months. I don’t think the wall thickness is mentioned, and neither is the amount of run time during those months. So there’s no frame of reference for what you could hope for from a home made unit for personal use. The metal is highly prone to rusting because it’s kept red hot and has acidic fumes flowing through it.

I agree about the stainless, or the replaceable part. After I build a proof of concept model, and a couple more test models, I want to build a nice big one with one of those two, or both features. Hopefully I’ll get the proof of concept started this weekend.

It may only be wishful thinking, but in the end I want something about the size of the gasifier in Francois’ thread about cogeneration. You know, the multi story thing with a conveyor system to feed it. There’s a ton of small lumber mills around me.

In case you are interested in what one looks like here is a photo

Neal

Wow Neal , that’s some fine looking machine , hope your in a position to tell us more about it or maybe even a video of it running .

Dave

Oh and i almost for got to say it so … welcome aboard from Downunder

Hello Neal,

Very interesting your system, and what I like most is simplicity.

Looking forward to discover your work,

And it is transportable:

Thats fantastic now jump in the truck and bring it round to mine so i can have a closer look

Cheers Dave

Nice build Neal!

Could you describe it for us? What is the big tank on the left? What does the control box looking thing do? Is the smaller tank to the right the Riche’ style retort? Are you running the generator off of it?

I have questions for anyone who might know, about the nature of the gas produced. I know it’s richer than gasses from partial combustion gasifiers. Is it rich enough that engine power isn’t sacrificed? The gas also has a higher hydrogen content. How will this effect engine operation? Would it require adjusting the timing?