So, anyone who has made charcoal knows, there is a lot of wasted potential in the process. Especially if you’re making it by destructive distillation in a sealed retort, you’re probably thinking “there’s just gotta be a way to harness those gasses.”

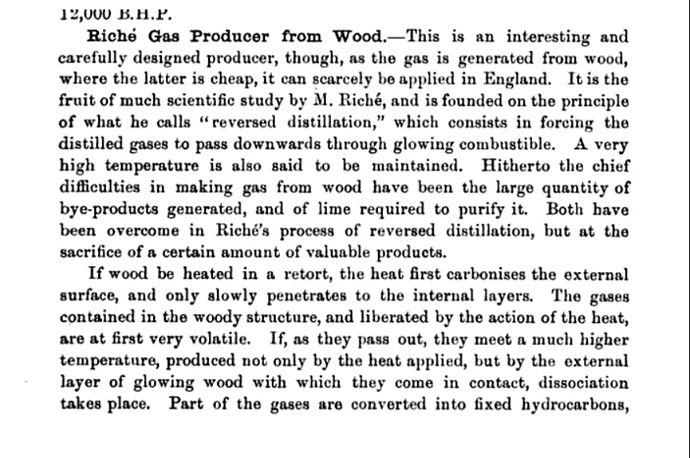

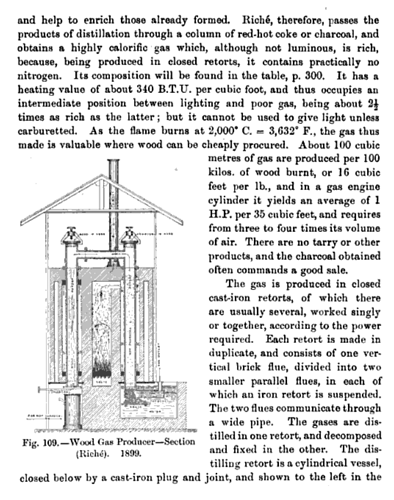

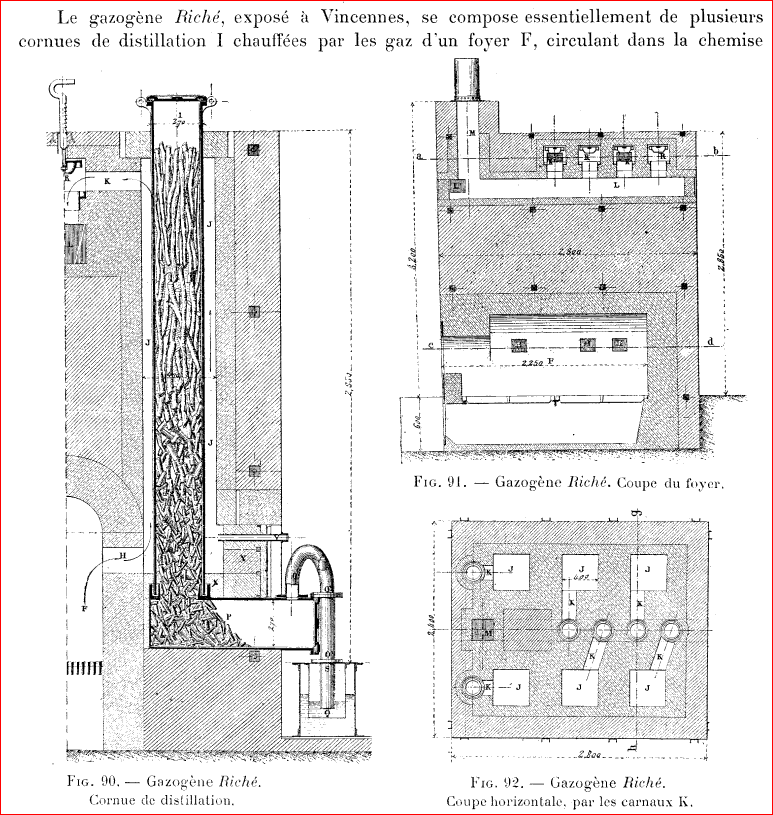

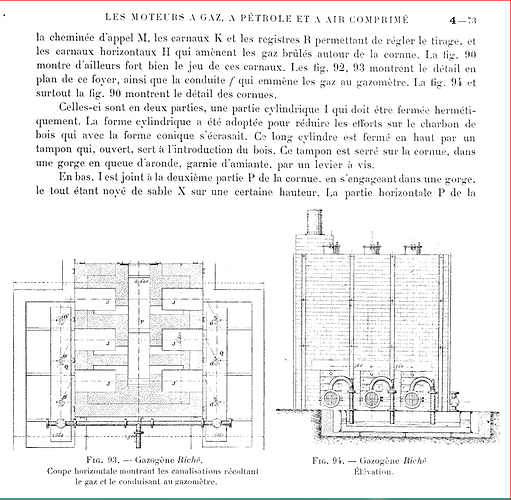

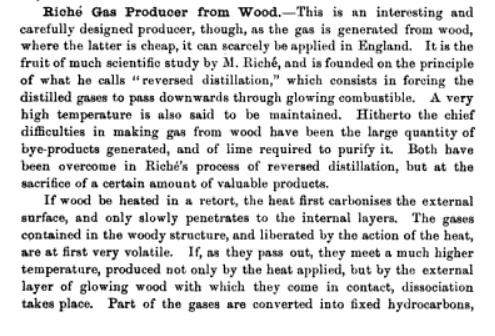

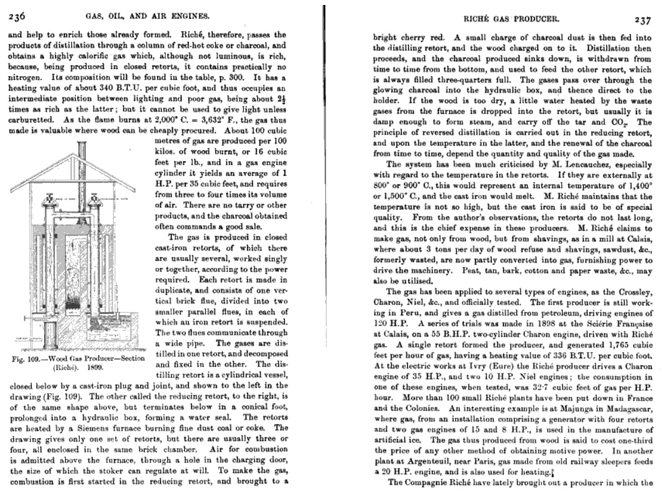

There may be a way. The Riche’ Retort gasifier was developed about 120 years ago, and according to books about gasifiers from that time, seems to have been able to clean up the gasses from the destructive distillation process.

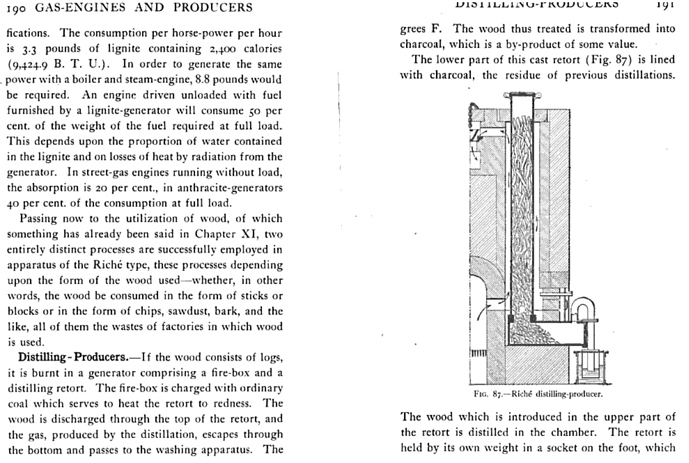

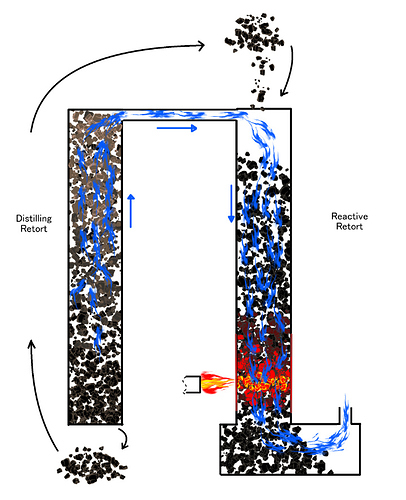

In a very small nutshell, it is a tall, relatively slender (10 inches or less) tube, with a portion near the bottom heated to cherry red. The charcoal in this portion would have been glowing hot. As gasses formed in the retort, they would have to pass through this zone of hot char on their way out, which should crack the tars and various other hydrocarbons into basic components, CO, CO2, H2, and some other light odds and ends.

I’m primarily starting this thread to share this “lost” bit of gasifier history. But also because I felt like I hijacked Koen’s thread about a tar cracking device.

I’m putting it in the charcoal section because even though the charcoal is technically a byproduct, I’m sure a lot of charcoal users will be interested in the information.

This thread is more about the original Riche’ Retort gasifiers, and any related science or theory behind it’s operation. I’m in no way shape or form an expert on the subject. I just stumbled on this design a couple of months ago. I plan on posting the pages from the books I found references to it in. Then I’ll try to put it in modern English as best as I can. Anybody with gasifying experience, or knows chemistry, or thermal dynamics can correct me if I get anything wrong.

I’ll have another thread in projects covering the building of a Riche’ style retort. I will probably be making some slight modifications, and possibly testing some theories on that thread. And sharing my general interest in gasification.

I’m away from my computer for a couple of days, so I can’t upload any of the images or notes I have about it right now. So stay tuned for more in a couple days.