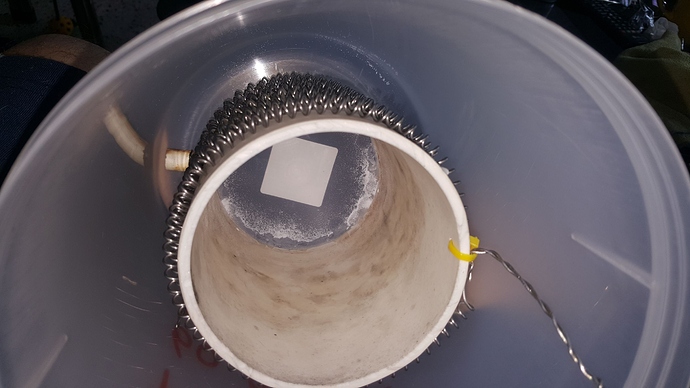

Any updates or new developments with this project Koen? I had a similar idea for cracking tar, just using an induction heater instead of a resistance heater. Like this one http://inductionheatertutorial.com/. A resistance heater like yours probably makes more sense though, simpler power supply. Plus resistance heaters are more efficient for a long run time.

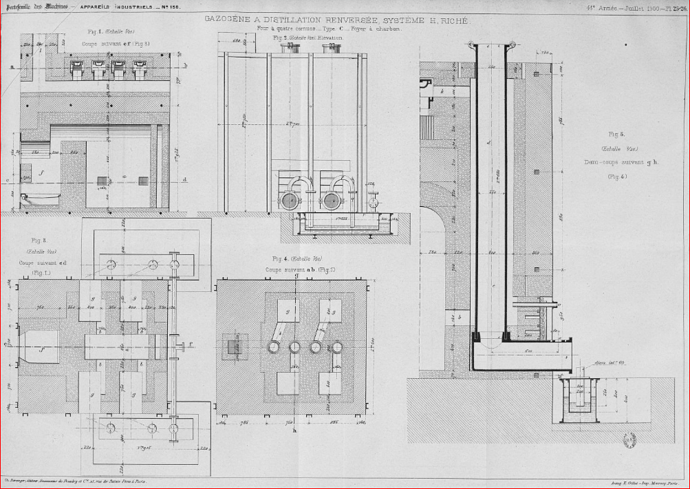

You should look up the Riche’ retort gasifier. It’s a french gasifier from the late 1800’s, early 1900’s. As I understand it, it’s the same general concept that you’re going for with a zone of glowing hot char heated by an external energy source to crack tar. I’m hoping to build one in the near future. I might do a thread just on the original, just as an informative thing, and do a separate thread of my actual build, if and when I get to it.

Kristijan, I’ve done the same thing with my welder using gouging electrodes. Honestly a welder isn’t quite up to the task. While most will provide the 35 volts needed for a stable arc (not the little 125 VAC ones though), no welder I’m aware of will be able to create an arc at 100 volts or more. That would produce a nice long arc giving more energy to the electrons, and effectively increasing the surface area being heated by radiant energy. I’ll have to see if I can dig up an old patent I saw, I think it explains it better. Something from the 50’s or 60’s dealing with coal gasification.

As far as the life of the electrodes, if you know how to do any kind of electronics, an auto feed system wouldn’t be to hard to make. A comparator would read the voltage between the electrode and ground. As the rod burns back the arc gets longer and the voltage climbs (we’re using a constant current power supply), when the voltage hits a specified point a feed motor turns on pushing the electrode forward. Once the arc is shortened and the voltage drops the motor shuts off. if the voltage is too low, the motor kicks in reverse. Add an electrode magazine and every time an electrode runs out, another is ready to go. Or you can try to do what the big boys do and have an electrode extruder. Makes the electrode as it’s using it. If you make charcoal, you have the ingredients, raw powdered carbon (charcoal) and heavy tar. You’ll need to pyrolyse your wood and collect the off gasses, then distill that until you have the really thick, gummy tar. The kind Norwegian’s like to eat (no joke). Mix it up, put it in a hopper, heat it to make it soft, feed it through an ectruding device, heat it even more to cook off the tar and that’s it, as I understand it. The heat to cook off the tar can even be the heat from the arc as you’re using the electrode.

Not to get off topic, but an idea for either one of you since you like to experiment, large industrial facilities use “cold” plasma to crack pollutants, including creosote, in their smoke stacks. Cold is a relative term, it’s still screaming hot. Basically all it’s just an array of Jacob’s Ladders (the arc machine in mad scientists labs) that the gasses pass through. All you need is a transformer for a neon light, and a healthy respect for very high voltages. Then figure a way to put it in the outlet of your gasifier. Should be more efficient than trying to crack the tars by brute force like the two methods above, where you’re supplying enough external energy for gasification plus cracking. The “cold” plasma just supplies enough external energy to finish cracking what the gasifier missed.

be carefull for diabetes having such sweet life

be carefull for diabetes having such sweet life