I think my jet needs to be a few inches longer. Its not burning down evenly or is this what we want?

Hi Matt , when restarting up on old charcoal its always best to give it a stir around and try and get some newer coals in front of the nozzle so to make it more reactive , another reason that its best to try and get the size of your charcoal between 1/4 and 3/4 inch also keeps rat holes down to a minimum .

I use a small wood mulcher with hammers and a 1 inch screen in it driven with a 12 volt dc motor with a gearbox from a wheel chair plenty of torque and nice and slow so little flying dust works great for me .

Dave

Just found this item for sale on market place its a ice crusher so tempted to buy it for the $50 he wants just to see if it would crush charcoal

What size ? dominoes ? dice ? corn flakes ?

Im smashing the fuel down to about the size of a quarter.

Nice thank you, Yeah Im a noob here all over again. haha Thank you guys for the advice

Hi Matt,

Size does matter, a lot, the upside is the ease and reliability of the system with good fuel prep.

I get my best results with a spread between 3 and 12 mm (1/8 to 1/2")

Sieving that is a piece of cake.

The gas temperature stay’s low, the gasifier relative cool , gas stay’s dry.

When you overdue the waterdrip, then your charcoal becomes moist and a pain to restart next day.

I adjust waterdrip according to my load needed, with a baseline 1 drop per sec, (20 drops equals 1 ml ) = 0.18 liter/Hr for each Kg of charcoal consuming.

The max i went up to this date = 1 liter /Hr per Kg charcoal, but then i am running the engine at max and use the exhaust wall surface to turn the water into steam before injecting that into the gasifier

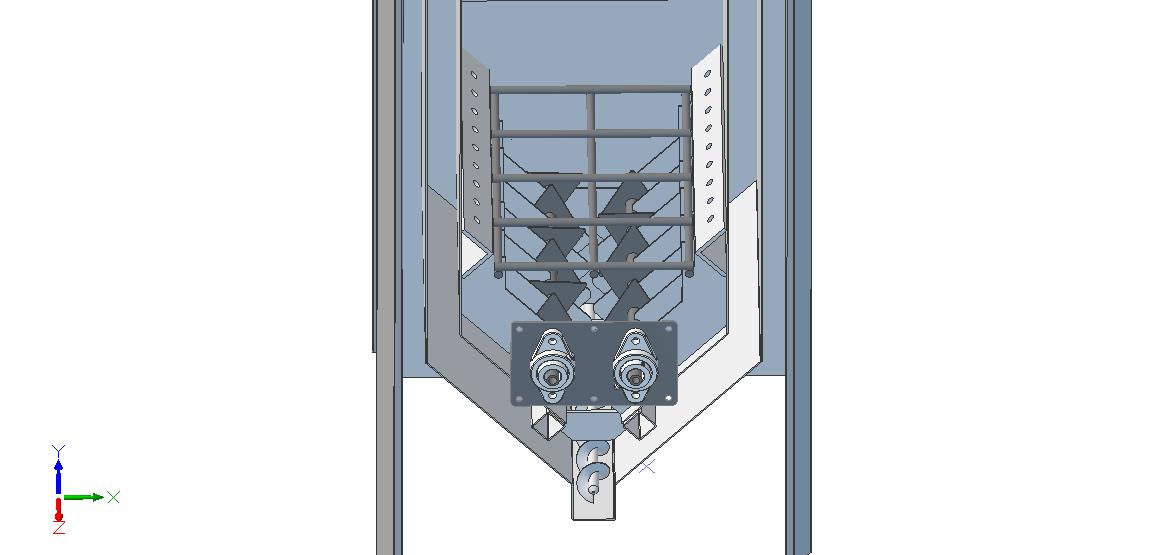

I tend to run the level of the charcoal bed not lower then 24" above nozzle, that certainly helps ,in my case, to have good power output.

Ok yeah I can only get about 2/3 of the hopper that will run stable. So that make sense.

Yeah the water drip is impressive, when I get it good and hot I can dump quite a bit of water into that thing. I think a more refined with steam flashing and automation controls could really improve this.

Cheers, thank you for your input

Hi Matt , is this still a cross draft ? or have you converted it into a updraft ? can you do a sketch or explain how you have the inlet and outlet positioned and the distance between the 2 if it is still a cross draft .

Thanks Dave

Thanks for the numbers Koen. How big is your motor/generator with that 24’’?

And what happens if you throw the charcoal dust in? There is effort in that too. A waste to throw in the garden.

I look at the dust or “waste” as a plus for the environment, biochar. Add it to the compost pile, and you have taken excess CO2 out of the atmosphere for thousands of years, and made a permanent improvement for the soil.

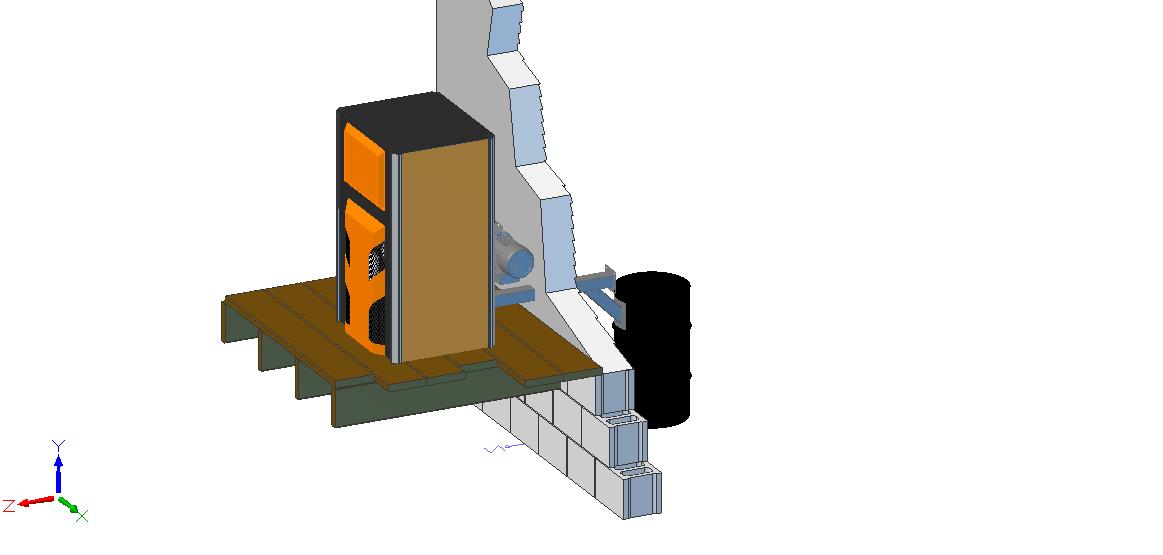

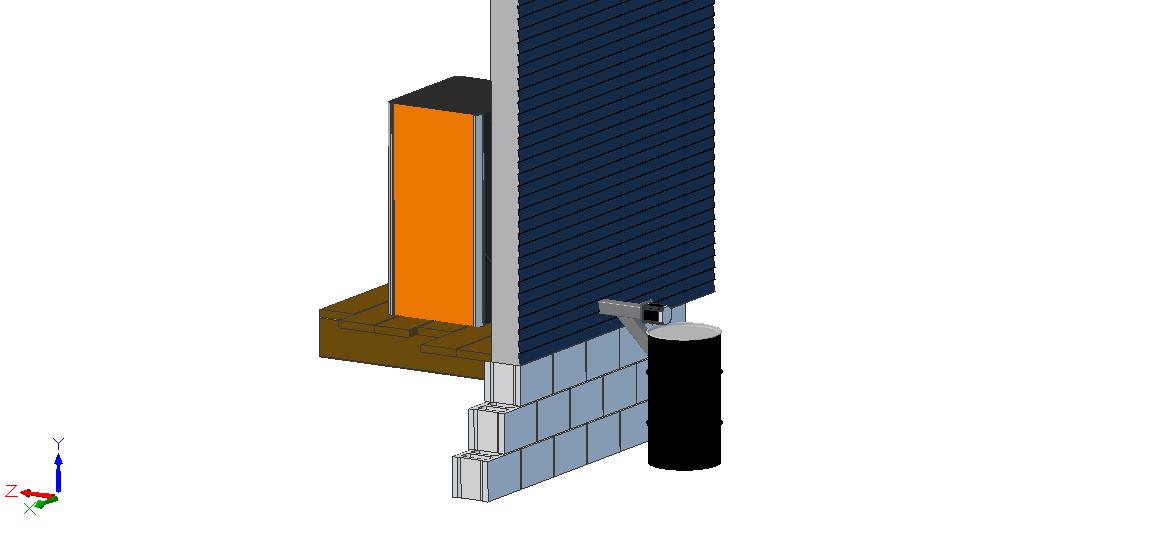

The hopper at the nozzle level extends 11" back. There is a gas pick up tube welded to the back. However this does not extend all the way to the jet level. Originally it was 6 inches higher. It is now about 10" higher giving the gas a larger area to penetrate through.

The gas pick up tube extends up to the top and transfer the gas to back bag filter chamber.

If you allow dust in the gasifier it will end up in your filter clogging it up prematurely. One of the first lessons I learned it filled my bag filter up in two runs. I screened it out after learning this and the filter stays clean.

A good processor can keep this to a minimum. But like Gary has explained it is very good for the environment. You can save this as well and sell for lots of money. 1 ton of biochare sells for $2500 USD here in the states.

This is why I like pellet fuels as this is no waste. When you chip fuel this is even more of an issue. Char pellets will also have less dust waste with much higher energy density by both weight and volume.

Hi Joep,

the 24" or 60 cm, comes from experience, it is also the diameter of the reactor playing role.

Finding balance between the descending fresh fuel (cold) with the ascending gas (hot) is the key.

I strive to get an easy breathing charcoal bed, so i don’t want the dust or small particles <3 mm in the charcoal.

It will clog up the gasflow and that is what you want to avoid.

Cold gas and minimum restriction of flow = best quality and best power output

Smaller than 3 mm, is excellent as filter adsorption material or for agriculture purposes.

Thx Koen, still calculating over-here. We use 1600 m3, 6400 gallons natural gas, that means 3200 kg/7000 lbs, and that equals 64 barrels of wood to burn or 256 barrels if it runs through a gasifier!!! That is way to much. Just ordered a heat pump to divide this in a factor between 2 or 4. Crazy, if you calculate what your needs are. But a charcoal gasifier is the best choice between buildings. I didn’t even calculate the difference between charcoal and wood…

SO, good work Matt! You are completely off grid! Wow!

Joep,

Natural gas is not used up here, but back in the days an avarage house consumed about 3-4 m3 fuel oil (diesel) a year for heating. How does that compare?

What about your Atmos boiler and storage tank? Should be able to satisfy your needs on wood without too much effort.

JO, I don t want to disturb Matt’s topic to much, but 1 m3 oil is about 1000 m3 gas. So 1 liter diesel equals 1 m3 gas.

Atmos is doing great, only a little to small. I found a way to lite the little thing without smoke. Fill it once more and the buffer (2,5 m3/600 gal) is full again. That is doable, we would need about 4000 kg/8800 lbs wood. Even less if I fix an extra heat exchanger in the exhaust. Parts are bought, only need time to fix it. Gasses leave 250 C/480 F, that must be below dew point for the latent heat. Funny, a condensing woodboiler.

Here in NL, solar power is very nice organized but suffering from it’s own succes. All the electricity that is generated in summer, we can use for free in wintertime. The grid is our battery. Now, all good things come to an end, and that is going to disappear.

Another thing is that the government is subsidizing electric vehicles. A deal we couldnot resist and bought one last year.

These two things together makes me think I need a CHP for the wintertime. Calculation about produced heat and electricity come together very nicely. There is one minor detail. Modern society is very very energy-hungry…

So that is my quest and how I ended up here.

I didn’t see this post. I am a bit behind.

Welcome to the darkside. I kind of wish I had the rotary chunker for branches like the I think rebak. Or this is the same principle. Just to get more density then trying to throw branches in. I’m too cheap to get one though… lol It would greatly improve the automation part.

Too much cost its not marketable. Need to find away to make a typical pellet or wood stove produce fuel grade charcoal for free. Then we have a viable product. processor cost is eliminated, and your power is now looked at as a free byproduct of the system for just heating your home. That you are going to anyways.

If I buy a chipper that is what I am getting but I have to get the pto on the tractor working first. swears But I agree it is a niche product and hard to market especially at that price.

that isn’t the hard part. throw a coffee can with holes in it. The hard part is getting a continuous flow of fuel -and- not creating a mess or getting char dust all over the place.

Ya got to keep up man!

There will be a pellet fueled version based on current reactor technology. The grate will be active and designed to control the output of the char pellet production. If you want more heat for what you putting in, you can turn it down. If you want more charpellets you simply turn it up.