I made a simple charcoal crusher. It’s just a 3 inch ID pipe eight inches long cut in half. I welded a plate on to that so it looks like a big J I took another piece of 2 and a half inch OD pipe and welded a few rows of half inch all thread around on that. I centered a three quarter inch rod in the smaller pipe and made a plywood box to mount the J onto. The rotating pipe is just installed in holes drilled in the side of the plywood box with a hand crank attached. There is a sheet metal diverter plate that keeps the charcoal directed to the grinding area. I put a chute on the bottom that just feeds into a five gallon bucket. It will grind five gallons of char in a couple minutes. Then I sift the stuff in the bucket through different size screens for different applications. Mostly garden char. Simple, cheap and works well.

Tom I would like to see a picture of that. Is that something you could do?

sure. How are pictures posted here? It’s pretty crude. I threw it together in a couple of hours.

If you hit reply, in the top of the reply box there are 12 or so icons. The sixth one from the right looks like a picture. click on that, and it will take you to the upload box. Then you can “choose files” to upload. Get the photo you want into your computer, or directly from your phone. I will have to try it again to make sure I described that correctly.

OK, That was weird. I never uploaded a freshly taken photo from my cell phone before, but it went!! Here is an Argos 2019 still…

Hi Mat

do you mean injection of pressurized water vapor into the gasifier air nozzle?

Off topic comment on Garry’s post #1130 above. If you want to use biochar without a compost pile, don’t forget to inoculate the biochar or it will suck up nutrients the first year in the garden. Urine is full of nitrogen and a great inoculant. A bucket full of charcoal fines is a great odor-free urinal for the shop.

No just steam no pressure, water drip on something that will flash it. Like engine exhaust. You dont even need to flash you can simply drip directly into the nozzle.

i built something similar on my toyota 22re pickup. the “droplets” of water volatilize on the exhaust pipe before being swallowed by the nozzle

I would like to pressurize the steam to produce a venturi effect on the air entering the nozzle (to compensate, a little, for the pressure drop of the gasifier)

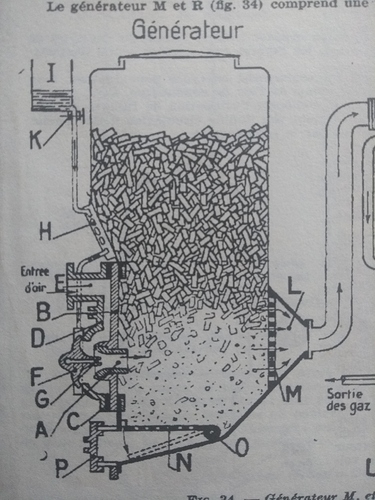

here is my source of inspiration. We can see in this drawing a nozzle for the water vapor in the axis of the air nozzle

if the steam jet enters the nozzle at high speed, the air is sucked in by the venturi effect

this configuration pressurizes, slightly, the air in the generator and reduces the pressure differential between the inlet and the outlet of the gasifier . What do you think ?

Excellent idea. This suggestion caused me to close the circle on the humanure toilet concept. Ground charcoal added to the organic cover material will greatly enhance the whole system. Odour control will be enhanced. Though not much of an issue in the original system, this will offer enhanced odour control. And there could be no simpler or sounder way to pre inoculate/ pre charge biochar and deal with the human waste problem.

Matt,

Do you have a link for the material you use for high temp gas hose? It looks like probably wire reinforced silicone.

Did you find your leak, Steve?

JO, I reported on yesterday’s tests in the DOW Driving Habits thread. Everything so far has checked out OK. Next is a cleanout and nozzle inspection sometime in the next few weeks. Some have questioned how much flex exhaust may leak. I use that between my cyclone and filter, so I thought I would ask Matt about his alternative. I’ll report the rest of the story later. Thanks for asking.

I get the high temp hose from McMaster Carr.

Look up High Temp Duct Hose or see this link https://www.mcmaster.com/duct-hose/high-temperature-flexible-duct-hose-for-fumes/

Matt,

Thanks for the link. Wow! that is expensive stuff. Guess I’ll stick with flex exhaust.

This is why I only use it as coupling. Ive gone away from pipe flange connections. Simply mate the pipes together using this as a high temp connection with hose clamps.

On charcoal units I dont offer any attachment kits. I leave it up the user, if they can do it on the cheap than that is great!! Otherwise its all the things like this that drive up the cost and there is really no way around it if you doing things the right way. I dont skimp on the stuff I build and this cost adds up.

Matt,

I’m not sure whether I discovered this company or someone posted the link to DOW. I’ve had this link in my bookmarks for a while. It looks like the same product to me, but with lower price:

Nice find, I now have it book marked too  Yeah when we get into cost cutting we will look for cheaper sources. One at a time build to order; McMaster is cheaper once you factor shipping from all the independent sources.

Yeah when we get into cost cutting we will look for cheaper sources. One at a time build to order; McMaster is cheaper once you factor shipping from all the independent sources.