Stuck some paint on this bad boy today. Going to kick some butt on it this week

Getting closer, a few loose ends mechanically and then Ill be ready to run wires. I played with the controls a bit last night getting the USB CNC card working with a LattePanda PC, wireless mouse / kewboard and a really nice 15" portable flat screen monitor. It has a hand pendant that goes with it too. So far its all bench tested nicely.

a 1000 likes for your work Matt…

Hi Matt,

I’m almost certain you you must have considered using an H-bot drive at some point. Curious as to what made you decide against it? 45° rotation?

Rindert

That would be cool for a 3 Printer but that will most definitely fail with a wood router head,

Yes, it would. Nothing beats rack and pinion.

Thought it was xy core at first sight. Don’t really know why people use that or h bot instead of just xy uncoupled.

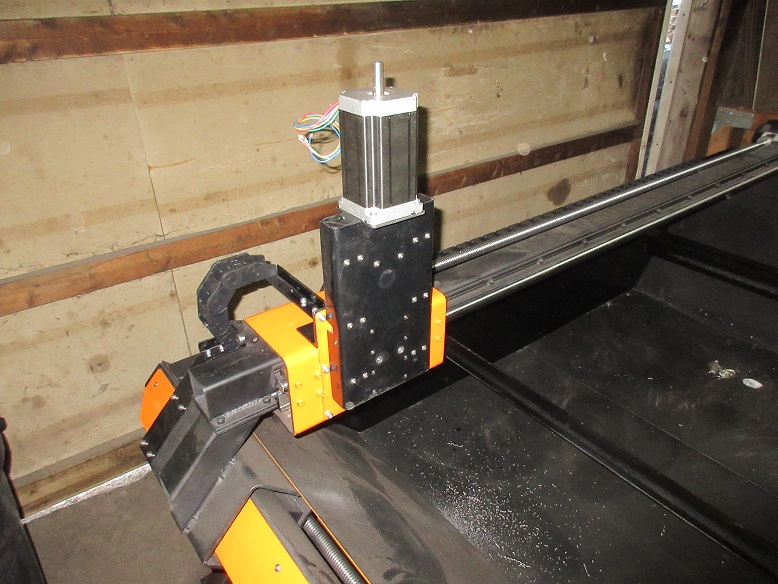

This has precision 25 mm ball screws with zero backlash. The Y is set up with anti back drives as well so the any load apply can not fight the motors. This is what you see on $100K cnc machines not the hobby grade.

Aha. Now I see.  . But I don t need glasses! Or I won’t

. But I don t need glasses! Or I won’t

They are not going to shake at full speed, with the bridge at the end of the table?

Its about as ridged as I can make it with out going to solid base construction. This is why the Y Axis has it ways inverted and at a 45 angle. Plus all rails have dual precision ways.

For wood routing I think it will do fine might be able to machine aluminum. But chatter all depends on the guy setting up the cut paths. Need to learn the table limitations and then stay with in those limitations.

The week link here is the Z Slide on this one. I can build it more robust but I dont have funding or time to do so.

So this here is the James Webb Telescope. I cant say I built the machine as that predated my employment with Campbell. However I was the guy that serviced the machine that ground and profiled those hexagon mirrors. The Z axis on that machine had a stationary ball nut and the ball screw moved with the head. This head with the grinder spindle had a weight in excess of 10,000 lbs. The ball screw kept failing and destroying those mirror plates. $100k a piece and months worth a work as it takes over a month to grind each one. The screw had been replaced a few times before my employment and no one could figure out why it was failing. I eventually uncovered this issue after at least two screw replacements I performed along with re alignment attempts. What I found is; the stationary ball nut, was flexing a 1" thick plate that it was attached too ass the Z slide would move up and down. If the nut is tilting down then this creates a ton of stress on these screws as they are zero tolerance. This causes heat, things expand and now it amplified. Big wigs from JPL came in there and I had to explain to them why their multi million dollar toy was destroying $100K parts. I drew and exaggerated picture of the screw and when the CAD stress analysis was sent you could over mine on top of it and it matched near exact even the scale of the drawing was near perfect. lol .

So what we did was; is we installed a nitrogen gas over hydraulic counter balance onto the Z slide. this kept a zero gravity load no matter where it was positioned and wallah all fixed. I dont know what the material is they made those out of. They are not gold, that comes after this process. I did see the chambers for gold plating though along with pallets of gold. I was never supposed to know what they were grinding on that thing. But I saw the part on the table once as they were not ready for my arrival. So that along with Hubble Pictures plastered everywhere and this being a subsidiary of Northrop Grumman and JPL I put the pieces together. lol. Campbell also built the machine that ground the mirror for the Hubble as well. That was done in Connecticut I think right down the road from where Bridge Port manufacturing once was.

I really enjoy stories like that. You had a hand in building an important piece of history.

My 50 year heavy construction inspection career made many “things” that still give me pleasure to reminisce about.

I remember a magazine artical about casting the Hubble mirror in one piece of glass. They built up the mold and set it on a turntable at a particular rotation speed, and the molten glass formed a near perfect shape. Then Mercury was vaporized to form the reflective surface.

Yeah Campbell Grinder does a lot of government and or government contract stuff. This is only one instance of some of the classified projects Ive worked on. If you have flown on a commercial jet, regardless of where you are in the world. You are flying on parts produced on a Campbell Grinder. This company is over a 80 years old and played a crucial role in the aerospace industry in the 1940’s. This company was originally founded by Frauenthal Grinder Co. as he was approached by the Navy to produce a high precision bearing for gun mounts. This evolved into jet engine parts and refurbishing along with another local business that used this machinery for high precision bearing production. Hugh Campbell would later become the successor and create Campbell Grinder Co as he was the man that engineered and created this machinery.

So as a field service repair engineer Ive traveled all over the US and parts of the world servicing these machines in various industries both civilian and government. Ive been to places that build nuclear reactor technologies. (Curtis Write) military guidance systems, (cant say another work on that one) any place where jet engines are involved Ive been there, (Pratt Whitney, GE, Rolls Royce, Sikorsky Aircraft and then all smaller suppliers. all your bearing manufactures, etc. Any bearings you have or use chances are they were produced on a Campbell Grinder. When at Sikorsky Aircraft they showed me where they maintain and refurbish the jet engine parts for the Presidential Helicopter. Partly so we dont end up over there and get shot I suspect. That area is guarded by a solder with a locked and loaded M16 and they said he will shoot you!! lol. Yeah most these places are huge small cities GE in Boston has its own zip code it is so big.

So yeah Ive seen a lot of stuff during my time at Campbell, but 5 years non stop travel was plenty for me so I started a gasifier company!! lol.

Anyways its getting closer it has wires on it, probably put power to it tomorrow.

Interesting life Matt!

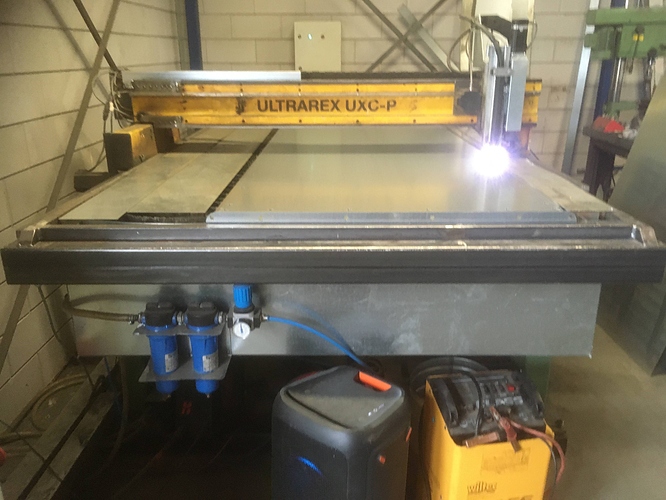

Nice router, or is it a plasma? Small shops are waiting for this. My next build will be with Linuxcnc, consider that. Very stable with ethernet.

The bikes is a good idea too now with the Covid. No bicycle available over here. Specially electric ones.

Its both, it will be use primarily as a plasma cutter but the client wanted to be able to run as a router as well.

Ok, looks good anyway.

It is fun to build machinery. One of these days I start with a gasifier. Couldn’t wait with that simple fire and burned it right away. Was fun. Flare of 6 foot for a few minutes and then everything started to melt. Ventilator was from an old pellettransporter and way to big.

I will post a picture of my plasma, maybe you get some ideas. Old one is an Esab retrofitted, the new one is started from scratch. Shop is to full now. Boom boom Becker and work is over again and time for playing.

My plasma cutter(s)

Esab retrofitted with

Hypertherm only 45A!!! more then enough

UCCNC controller from Hungary

Neuron Lite THC, top quality from Russia, with love.

WEll, pictures is not working today. Better get a coffee and try later

The new plasma gets square backlash free guidenance instead of the rollers Esab.

Steal is forklift proof 8 mm 200-100 mm profile. On top the plasma, not started yet.

Under is 8 tons of steel, that saves me a lot of room. Plates are 3-1.5 m, thin plates 1,25mm and 2 mm, package 2 tons each.

Controller is planned Linuxcnc with thc. That save me 1000 euro/dollar.

Close up

Ok, me and computers??? Bad combo! And every thing is cnc here, or rebuild as cnc. This is the old Esab. Promised my wife back in 2000 not to buy anything that year. In februari this one followed me home. Year of build is/was 1985. Still going strong!

Nice weld, looks like robot laid that down. Very nice machine!!

Thanks, Neuron is the way to go with thin plate. Above 3 mm Proma 150 is a good option. Cut with ghat one gor years.

Shit I am tired. Having some jomebrew applecider

matt you said you got a pellet making machine for making pellets could you tell me what the speed of the rollers for the plate is. I was guessing around 300 rpm maybe but if you have one did you ever check the rpm