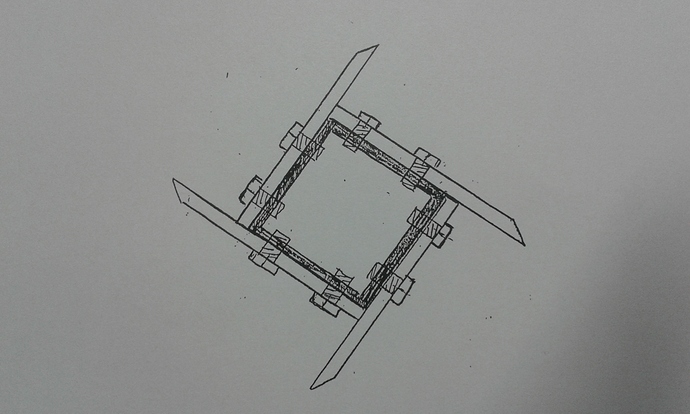

Found this , thought it may help to build one. I noticed some only have one set cutters. Is there an advantage one way or another? http://www.ujcy.com/tpkova-samodomo-ZTQxYjV4LUQxUEU.html

Hi Al,

I belive double cutter machines may be able to cut slightly sturdier limbs still using a small cutter diameter (short chunks). On the other hand the single axel machine would be a lot easier to fabricate. Needs no machined gears.

This is a pretty naked machine that allows you to see what’s going on.

I did some work on rotary dye cutting machine for labels a few years back they use a rotary cutter wheel with different knife spacing to get the correct label length running against a mandrel roller on the bottom side. The circumference distance between the knives determined the cut length assuming the media travels at the same surface speed with no slippage. I assumed the reason for to knife wheels on these clunkers is to insure one knife is alway engaged in the wood pulling it through the machine until it is cut off. With only one knife wheel and a smooth surface on the other side I think there would be alot of slippage and prices of wood just not pulling through the machine. Only speculation on my part but you can see a similar problem with a wood chipper working against a sheer bar.

Hi Jan, Can you give some average dimensions on cutter size, shaft, and gear diameter, and how cutters are attached to shafts? thanks

I agree. I think some single cutter youtubers use a roll as an envil instead of a fixed bar.

My gear diameters are 120 mm and I know Kristijan is using 90 mm. Gives 2-3 inch chunks with four cuts per rev.

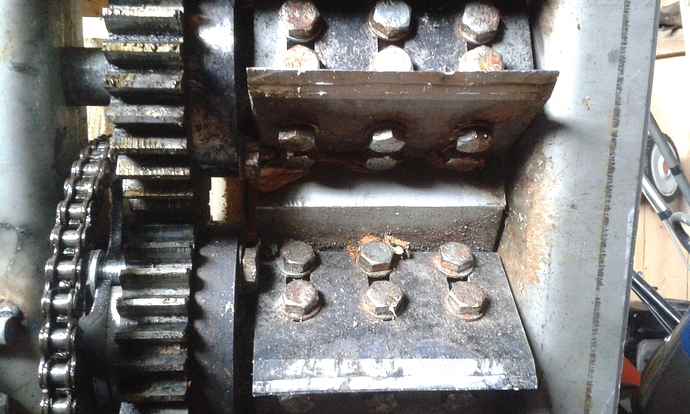

I did mine the farmers way with 50 mm square tubing as shafts and 6 mm ss plates as knifes. I attached them this way:

Chunking last fall.

Thanks, did you weld round shafts inside square tubes? What size shaft bearings? How wide, and long are the knives? Sorry for all the questions, thought it may help us get a better idea of it.

Hi Al,

The gears that fell in my lap happened to have bearings pressed into them. I pressed my own into the square tubing and bolted it to the gears. My 20 mm bolt shafts go through all them bearings. Bolts are at a standstill and attached to the frame. The bearings outer size I don’t remember but whatever fits into a 50 mm square tube. The knifes are 120/2+50/2 = 85 mm long and as wide as the bolts allowed, which in my case was about 5 inches. The narrower machine the sturdier. Less flex. If the gears had not come with bearings in them I would have made the gears go outside the frame and bearings onto it (the frame).

Well Iam way behind on this on.

Runnning out of daily computor time to detail read back up. Apologies.

Yes coorect their is no ablity to small lot sell sofwood market logs or lumber here eother.

The Washington State requirement that ALL lumber must be certifed, and Inspector stamped graded has killed this.

WHY my mill has sat unused since 2008/9.

Small lot saw grade logs do get firewood up. Premium market here for into Urban delivered fireplace wood. MUST be totally, all-white, super clean, never any bark or pitch.

Just like those premium white meat only wonderful chicken strips. What happens to the rest of the bird?

Actual funiture grade, machuinable, turnable, art-work hardwoods there ARE single tree marketable. Ship UPS, FED-Ex blocks and such. With Guarantees.

IF you can do all of the tree removal, the rough milling, somethimes 2’5 years settin out of the weather to cure-age, cash money can be made.

WHY the dark-meat needs to home/farm/shop woodheat. Gasifi for engine shatf power. Wood “wastes” eaters uppers.

J-I-C Steve Unruh

In Western Oregon, the State is mandating thinning. It makes sense. BUT, the price of chips is down to $25 a ton. There is a surplus of logs. You can get a log truck load of logs just by paying for the hauling. I’m thinking of getting a couple of loads. I got a big Husky with a 36 in. bar and a carbide chain. Only problem is; I’m down in California trying to make a few bucks. Also, the price of firewood is way down.

NOBODY has any money. The scrap metal yard closed down, no money. Or. raised can deposit to 10 cents. There are people walking for miles up and down the highway looking for cans. Even people living back in the woods are getting a lot of visitors looking for whatever they can cart off. I’ve already lost several $ thousands of stuff to the tweakers. I bet they would haul off the firewood stich by stick if I cut up the logs. The crash is really going to kick off in February. Then, the thievery will get really bad.

Interesting facts you have out west there. We don’t have high paying markets for pine pulp. But we can still sell logs here and there. And the market for low grade saw logs and high grade poplar logs has increased steadily over the past 7 or 8 months. (pallet shops mostly & cabinet manufactureres) It’s interesting you say there’s no money, because things are booming here. Everyone who is any good at doing something is covered up with work. Our construction company is scheduled out into next march now with no end in sight. My friend with the tree surgeon business is buried for 6 months at least. my brother got a high-paying job offer yesterday to build and set up another quarry in our county. This time mining geodes. It’s hard to find a sheetrock man, or a plumber, or an electrician to do sub-contract work because they’re all busy. Decent low-end labor is getting hard to find and getting more expensive because there are so many new jobs here. the current unemployment rate is down to 4.6% in June in AL.Pretty steadily dropping month by month since last fall. Factories are being built, manufacturing jobs are opening up. Wellborne Cabinet shop is expanding. Car manufacturers are hiring at Honda, Toyota, Kia, Hyundai, Mercedes-Benz, NABI (North American Bus Industries).

Shredable scrap (tin) is still bringing $5.00/100lb. Scrap thievery has been curtailed significantly with the new(ish) photo law to record all scrap sales.

Gas is only $1.85. Eggs are $.59/dozen and milk is $.99 a gallon. The general sense here is that things are a lot better than they were last year and are consistently getting better. There’s hope in the air again in these parts…

I wonder why things seem so bad on that end of the country and not here…Any ideas…?

And I am curious…This may be a question for another post or even a PM…but what is this “crash” in February I keep seeing mentioned?

WHOA ! Billy, you must be in a time warp. There are so many homeless in L.A. that the mayor asked the governor to declare a state of emergency. This isn’t the thread for it but, I’ll make it short. Ca. got rich from the Pacific Rim Trade. As the fortunes of China go down, so do the fortunes of Ca, and Australia.

Gas is about $ 2.70, eggs are about $ 2.20,

I’ve been writing about the economy for 10 years. Here is a link to the most recent page on the blog.

http://www.energeticforum.com/general-discussion/13014-economic-pressures-76.html

The most immediate thing that you should watch is the battle over the debt ceiling and budget. I can probably answer any questions that you might have.

BTW, with chips at $ 25 a ton, you have to think twice about gathering logs, cutting, drying,building a chipper and doing all the work.

Chris just made a catch all for rabbit holes and arguments…

Got the rest of those post oaks quartered. Knotless for the most part. And still no metal.

Holy wow you two have some big trees there. I sure wish I could find stuff that big on my property.

We use to drill and pack with black powder to split logs that wouldn’t fit on the mill.

No you don’t ! ! Dad keeps finding these big sockers, as he would call them, to drag out of the woods. Some how the Burg breaks them down to lumber. Been thinking about making some of those table tops for sale. I like small logs.

Billy, I never seen a two post Woodmiser before. Is that a new style mill for them ?

Us too. I thought about it but don’t have the powder. The saw was readily available and cheaper.

Jeff, I don’t know how old that mill is but it’s not anything close to new. The other (right) leg rides on the rail on a roller bearing just for vertical support.

William, If it’s a time warp it’s one I like…I’ll reference a Lynyrd Skynyrd song again . ![]()

Bill, We do have a good many large trees around. Not groves of them any more. Mostly yard trees and town trees. Usually dangerous because of metal. Wire, fencing, lag bolts, bullets, landscape stakes etc. I have a friend that milled a really old willow oak several years ago and found a civil war musket totally encapsulated. I think he made some money on that at some museum some where. We shipped a perfect, knot-less 7’ wide x 18’ long x 6’ 3" white oak log to North Carolina 3 years ago. It paid really well.

Kinda a sad story though. The lady that had us remove it did so because she wanted to put a pvc fence around her yard and was afraid it would get hurt by the tree. My conscience still bothers me some about that one. haha ![]() Trees like that shouldn’t get cut. Had a 5’ willow oak a couple years ago because the people were tired of raking leaves. Perfect tree. I thought they should have moved and sold their place to someone who would appreciate the resource that the tree was…Anyway…to each his own I guess…

Trees like that shouldn’t get cut. Had a 5’ willow oak a couple years ago because the people were tired of raking leaves. Perfect tree. I thought they should have moved and sold their place to someone who would appreciate the resource that the tree was…Anyway…to each his own I guess…

This one we are milling is 138 yr-old. It blew over in a storm a while ago.