Thank you for the up date. It is always interesting, the “solutions” that you come up with for problems that land on your table. As you must have noticed by the comments, not many of us would pick the soution that you use---- but, you are a “get’er done” type guy.

I worked for a company laying water mains for the city of Los Angeles. Never had to dig by hand over a couple of feet. Always had back hoes or a big trencher. I can look back a several times when we were working down by the beach and the ditches were all sand. A few exciting times, but I’m still here.

Don’t for get us–we are all interested in your adventure. Thank the wife for the video— tell her “much appreciated”. TomC

Had a great new years eve, hope everybody did too! Lots of good food and drink, with a prolonged sleep in the morning, all surrounded by family and closest friends. Butyfull!

Kinda milestone actionaly, wife and kids spent their first night in our house. Wife reports sleeping like crap becouse a mouse decided to investigate our cubbord with seeds and plastic bags, but l had no such problems. I had enough of the liquid sleeping pills in my head

This morning l took some pics for you guys.

Livestock grows fast and fat

Turkeys laying this time of year??? Shows how messed up our weather is.

Been laying thick lairs of old hay and charcoal in the stable under the animals, hopefully it achives some compostation (warmth) and l get some manure/mulch in summer.

This is the spring we captured.

Neighbour sayd God looked at me trugh his bigest window. Look at that monsterous rock. A day of sledge hamering, powerhammering and chiseling for sure. But there was a hole in the rock, just where it shuld be!

This is the ram pump reseroar.

And the shaft where the pump will be (shaft not yet installed

)

)Trench for the pump suply pipe.

Neighbor informed me he finished planeing the land where the sawmill will stand. I will get to it as soon as l finish the water buisness.

This hut will be replaced with a bigger one, for stacking/drying lumber and firewood.

The outflow from the spring we dug out.

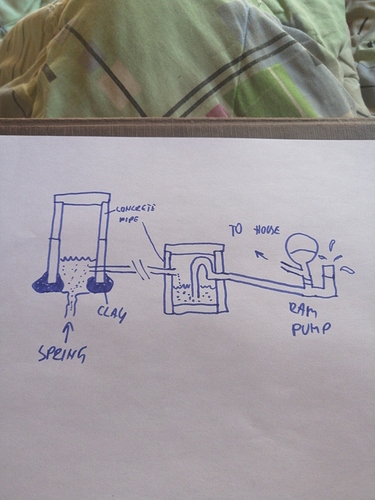

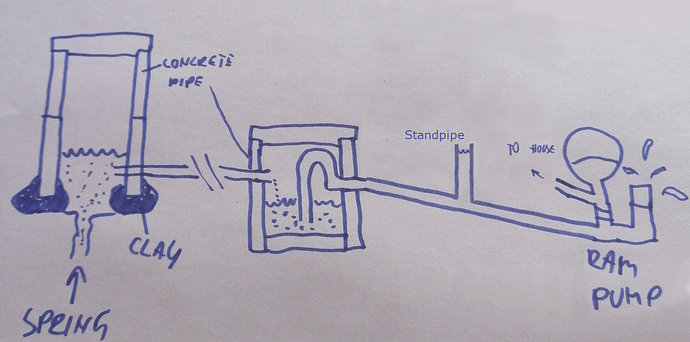

This is the diagram of what l plan to do.

The plan is the pump to have a kind of a syphone in the suply tank, when it runs out of water, it shuts off the pump. When the level rises again, the autosyphone starts the pump back. Hope the syphone doesent interfeer with pump operation.

Here l am laying the ring of clay over the spring, on wich the pipes rest.

Unbelievable and impressive work on the spring.

And one lucky turkey to see the new year.

The ram pump design should work very well. I especially like the self priming part, that will give a slug of air to keep the pulse tank charged

How much head is available to the pump?

When I see all of the trenches through roots and rocks I understand how working in short sleeves even in cold weather would not be a problem.

You are inspirational!

What Joep and Michael said. My arms and back feel sore just looking at your pics.

That spring is producing a couple liters per minute? How much do you figure you will be able to get to the house with a ram pump?

I am also sore just looking at all that work, but I remember being young enough to do projects that way. (Now I would be looking online at DC pumps and a little solar panel).

Glad to see you got “some” mechanical power in, to make a landing for your sawmill. Couldn’t see if that was just a bull dozer type of it was as I suspect an “excavator” with a bucket. That would have made your well/pipe line digging much easier. Looking good though. Keep the reports coming.

Have your wife and kids been sleeping back at your folks farm? How far are you from their place?. TomC

@KristijanL With the ram pumps I’ve built, I’ve mainly had issues with the pump self-starting when the head height is really low. Keeping the pump primed when flow has ceased is probably the most important part. Just make sure that the valve is able to open at a zero flow condition, and tune it (spring, weight, however you build it) so that it cycles more frequently (at the expense of being a bit less efficient and pumping less per cycle). That will help to ensure the best chance for auto-start success.

Separately, didn’t see it in your diagram, but I would strongly recommend using a standpipe to improve efficiency. Not absolutely necessary depending upon the drive pipe length, but can dramatically help with slow pumping.

Thanks for the thumbs up guys!

The spring seem to constantly produce about 3l/min.

Tom, thats a excavator. It might help some with the trenches bit the spring had to be duh out by hand. Its to delicate work for a bug machine, not to mention hydraulics some time rupture and having 5 Gal of oil dumped in your water is not a good thing.

Wife and kids stay at her fathers place, yes. Its about 10 miles away l think.

Steve, thanks for good tips! What is a standpipe?

Happy to help!

A standpipe is an open-to-the-atmosphere pipe rising out of a T fitting, placed between your pump and the water source. Like this (…I may have taken some artistic license with your drawing…):

Essentially, a standpipe provides a location for the water hammer shockwave to dissipate, helping to tune the operation of the pump itself. This can massively improve pump cycle time in some cases (by removing many feet of distance the water hammer wave front needs to travel before flow resumes). Standpipes make pump behavior more predictable across varying conditions. Without one, changes in water flow due to weather and season will often otherwise require the use of weights and springs to govern the behavior of the pump waste valve. The standpipe isn’t always necessary, though. This is a very useful resource that will help you decide, along with other tuning information, guidance about selection of pipe sizes, ratios for supply/delivery pipe lengths, etc.: Homemade Hydraulic Ram Pump for Livestock Water | Land-Grant Press

A note: the as-drawn water level in your supply tank will be where you must measure your head height, unless the supply tank and spring are plumbed in such a way that the levels will be equal. The standpipe level will be equivalent. It may also be possible that your supply tank is used to provide the same role as a standpipe, though the siphon you’ve drawn may prevent you from doing so.

Thank you Steve! Yes the plan was for the concrete reseroir to work as a standpipe, l didnt feel comfortable having shockwawes going back to the spring.

I filled the system with water for the first time yesterday. Auto syphone works but l messed up and missed it. Hope to catch it today. I am curious to see how fast it starts cause it shuld do so as fast as possible for the pump to start on a full pipe.

Even the litle one helped.

This is the future “engine room”. However l am thinking of enlargeing it and prepare space for a electric pump, in case we get severe droughts and the water flow is to low for a rampump.

I am allso thinking to install a second small rampump runing on this ones waste water, to pump water in a pond in the midle of my garden next to the spring, for agrigation.

Edit look at the drivepipe. It is 1/2" galvanised incased in a plastic pipe for corrosion protection. Its 12m (38 feet?) at a drop of 2m so a ratio of 6:1 wich shuld be ideal of what l read. @oregoncarl asked me why l put the asebly so far away from the spring. Here is why, l had to come to this part of the land with that ideal slope.

Looking good ! Your energy level causes envy

Definitely a good idea - would likely kick up some silt.

If there’s enough water flow for an electric pump, then there’s definitely enough flow for a ram pump. It’s really amazing how well they work, even in non-ideal situations: My tiniest pump works on 60cm/2ft of head height, 30m/100ft long drive pipe, and 7L/2gal per minute input flow. I guess the pump efficiency is probably what will matter more for you…if you need the volume/minute output that would otherwise be used as ‘waste’/power for the pump, then maybe electric will be needed during a drought.

The head height you describe and length seem like they should be just fine to me.

Sucsess!!! This is the first couple of strokes on this pump so bare with me.

Pump works good and it seems it runs just fast enough. Self start/stop will need to be adjusted. It runs exactly a hour on a full tank of water (75gal) and it pumps a decent amount of water about 35" higher.

Nights and long evenings are reserved for hayfeald clearing. 20 year old grass is tough to clear with any tool so best way to do it is with fire. The time is ideal; the gras has a coating of ice cristals from frozen dew so it burns wery slow, and the moon is strong so l can see all night long. I am burning a 6-10 feet ring around the faeld to work as a firewall, then l will burn the whole thing bottom down, with a fire truck on wach. Slow work but better safe thain sorry.

Oh, and the fluid displayed in the video is a mandatory equipment. Smoke is hard on your throat and requires rinsing, and the byproduct is used to wet/cool the wooden tool used to stamp/controll the fire

I heard Lasko is specialt made for that purpose. Is that correct?

Indeed  but how do you know of our local brewery? I dubt its so world famous…

but how do you know of our local brewery? I dubt its so world famous…

Congrats on the water pump!

Will you have runing water in the house?

As soon as possible!

Fire is an awesome tool if used properly. I could sit and watch a fire burn for hours and enjoy the entire time. This made me think we might need a flame view gasifier but it might cause wrecks being too distracting. I guess you can’t have all the fun at once.

Excellent! Great work as usual. The fluid displayed in the video was very necessary. I have a feeling it may have been used while commissioning the ram pump too - you know, for priming it and its operator.