The flame just died.

I guys the flame is back. I found out that the meterial is Bridging and when i vibrate the augur the smoke color is changing and its again back to normal

Guys the flame died after 6 hr of operation and i checked everything and even cleaned the ash out of the filters but still unable to make a clean burn.

What measurements do you have on system performance?

Some common measurements:

Temperature just above the grate

Temperature just below the grate

Pressure (suction) above the grate

Pressure (suction) below the grate

Temperature of gas exiting the filter system

Pressure (suction) of gas exiting the filter system

Can you graph these measures and coordinate them with time and observations that you make?

Pete Stanaitis

I would try putting some some air holes just before the end of your flare pipe or try sliding over a skirt with a larger dia around the end of the flare pipe that works well for me helps mix the air and gas , as i can never get a flare straight out of a pipe .

Dave

Max seems to be a respectable authority, and he states clearly that the test for good gas is a flare that can be lit with a spark, no open flame.

But given that you may have the most hours of running time of almost any group member, I respect your experience.

In this case though, it sounds like there’s too much humidity in the flare gas, likely too moist fuel, and too low temperatures in the reaction zone? Sounds like perhaps too small fuel particle size for the reactor also?

Faazil,

there is a French expression that says,

As we make our bed, we sleep.

and good for the gasifier, it’s the same thing, respect the procedure to follow to have a good result.

Dear all with your valuabe inputs i have come a long way (about 80 Pecent sucess). Can you kindly advice how i can run the gassifer ok smaller chips becuse the wood we get these days and just twigs. So after chipping most of them are just powder or very small pcs.

Further morw can you advice on how we can make a very good bed. When i switch the augur the whole layer is colapsing and going very low. For a moment we lose gas and again

it begins to produce.

Can you let me know how a good bed can be made

Dear pete,

There is no instrumentation on this machine i just added a temperature guage near the gas exit it reaches about 300C when i add raw meterial. And a temperate near to the flare its about 60C when the gassifer is running. Further two vaccum guage at the entry of the vaccum pump and at the exit of the gassifer

Guys i just mixed 50/50 of wood and rice husk we are maintain a flame successfully but its full if tar

Hi Faazil,

I think best would be to start over the “learning” process for you and your gasifier to get to know each other.

1: sieve out any fines and dust , smaller then 10 mm

2: sieve out anything bigger then 50 mm

3: only use anything between 10 and 50 mm for the time being.

4: Fill the empty gasifier with clean charcoal, even sized pieces, use the same size as above for guidance

5: only when all the charcoal is glowing and is glowing up to the top level, then ad slowly and evenly uncharred material but never completely cover the glowing bed.

6: learn to balance that consumption of glowing carbon with the feed in of new material.

7: start at low gas flow, just to get the good feeling in balance

8: stirr the lower part of the char bed regular to avoid bridging

FYI: rice husk does form very sticky ashes, slag due to the very high silica content. Don’t use that untill you succesfull know how to balance your gasifier at any given condition.

After as many hours as possible and only if you manage your gasifier well, then gradually change your fuel bit by bit untill you reach the limits of what is possible with your fuel and gasifier.

Question; what is your current location ? I am in Thailand, guess not to far away from you to hop over.

Hi i am in Sri Lanka. Its close to Thailand. You get plenty of flights

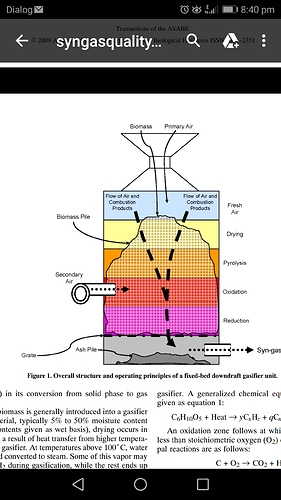

Small particle sizes and larger system sizes favour fluidized bed reactors. But they are a fair bit more complicated.

I was going to say use an updraft system which might fluff up the particles, and they are usually slightly more efficient, however, they don’t produce as clean of gas.

However this might give you an idea since it is downdraft.

In my opinion, it is very important to know the pressure drop across the grate. This can warn you of bridging and/or plugging. You “run and record” for a while as you take observations. Then you can begin to PREDICT changes before it is too late.

Also, I think you need to know the gas temperatures above and exiting the grate. This can tell a lot about whether or not the system is breaking down the volatile matter into CO and H2. Otherwise, you may get the tar that you are worried about.

I know that many of the people who “drive on wood” have a good sense of knowing how the process is going by sight, sound and “feel”, but sooner or later you are going to have to rely on operators who lack such sensitivities. They will either have to make adjustments “by the numbers” or have a controller to do it for them.

Pete Stanaitis

Also, I would think that you would want to limit the gas temperature to some maximum value, such as about 40 degrees C where it enters the engine. For now, while you are apparently testing with only a flare, I’d still try to get it down to that range, in preparation for the day when you do connect to the engine.

Guy with the rice husk i have a new problem the bed becomes thin and thinner and its sucked way from the root blower vaccum. The oxidising layer is just very bottom of the gassifer.

Shall i insert some nozzles on the halfway of the gassifer and bring up the oxidation layer. I have attached Pic of the plan