Hello George, you are using a motor from a 12V fan for the blower and you have limited the speed with a resistor made of 45 Ohm wire, which acts as a voltage divider or pre-resistor. I intend to say that if you usually drive your blower muffled, you can replace your pre-resistor with another more powerful 12V motor and an eccentric weight on the shaft, ie two motors in series. The blower will run at almost full power and the vibration motor with very limited power, but the total consumption will be less than the blower itself at 12V.

Or put weight on the ventilator or take it away and there is unbalance and your shaker?

I am very impressed by your lifestyle!

Giorgio, are you blowing into the nozzle or sucking through the grate with your blower?

hello don, the blower blows into the nozzle, not sucking, and the gas stream goes upward, not through the grate, because it is an updraft system…today i have seen the pages from koen van looken in thailand, he uses a 5 inch diameter pipe as hopper and oxidation. i think in this design the fuel slides down because the fireball in the oxidation has nearly the same diameter than the 5 inch diameter pipe…bridging is like a vault of bricks, for example , and this can only stand when it has a basis besides, so i think when the pipe is narrow like koen`s design, the fuel finds no basis besides and cannot build a vault-bridge, because the wide as the pipe burning area not allows this. my theory.

my other gasifiers are downdraft and sucked by the motor, and also when the gasifier stands beside and is only connected with a longer hose to the motor - also no motor vibration on the gasifer- the gasifier works for a longer time without disturb, i think because the sucking effect of the engine helps to bring down the fuel and dust and ash and so avoids bridging.

koens design seems -see fotos- to been not vibrated, they stand besides when cooking.

have you another idea?

to joep and tone, the gasifier is heavy, and i dont think additional uncentric motor or weights would make a lot of sufficient vibration, actually the gasifier -hopper has double height because i made him higher of the lenght of a complete propane tank for the try with the inner pipe…i think the design of koen is at least the solution, my theory on the response to don mannes …

first i will try to modyfie in downdraft, that is not so difficult, than i see if something changes. one thing was nice with the actually higher hopper - the gas come out very cold, one can let the hand on the lid, it was no difference of temperature burning or not burning-of course with fullfilled hopper, with half full more heat comes up…

i have just a nice 5 1/2 inch pipe besides for a koen design, both usable updraft and downdraft…

here some pictures of koen`s small pipe gasifiers…

hello tone, i think you mean like a ringfire? like in woodgasifiers, more nozzles, i thought also about this, a ring pipe with 5 or 6 nozzles, but the glow than would be very weak, because of 5 holes instead one, and for the kitchen cooker a soft airstream that comes from the blower seems more than enough for cooking.

the full power of the blower i use only for lighting the gasifier…

Kristjan used a flute, a tube with holes, for his rectangular carburetors, to blow in air, where it worked well. A round unit of larger diameter, when yours is, needs a ring-shaped air intake, so the fuel collapses evenly, at least that’s what I think. Even 5 to 10W of electric power to drive the engine with an eccentric boldly shrinks your gasifier even though it is massive, if you have the engine on hand try it.

thanks tone, this rectangular gasifier from christian i have seen on a foto here…

i think also a ring shaped air intake could be the solution…my gasifier has about 30 cm diameter…

Otherwise I wouldn’t like to be too wise because I’m just a beginner in building carburetors but I can say from my experiments on charcoal that adding water vapor greatly improves gas. My brother Primož, who is a doctor of mechanical engineering, even suggested adding water vapor in the gasification of wood, although here we try to eliminate excess water. He said, overheated dry air blown into the center of events forms only CO in the first impact with burning charcoal, superheated steam mixed with air can also form H2 or even CH4 in this area, I will definitely try this. I also recommend insulating the gasifier, as this way the energy is used for gasification and not for heating the surroundings and the gas will be stronger. Greetings! Tone

an old bigger sized tire as base under the gasifier makes a very elastic unit, what can be easy combined with a excenter-electro -motor to create vibrations- only a idea from yesterday…but in the moment i will try the design with a small pipe first…

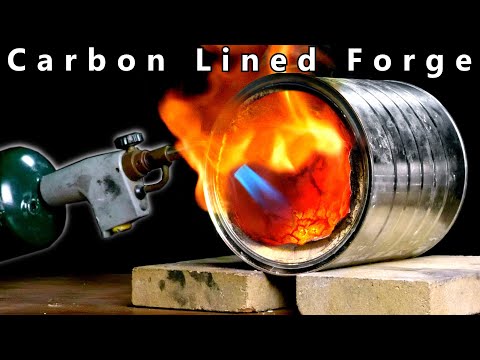

the blower though works really well, see flame on the foto, and this is not yet full speed, in every way seems more than enough for two cooker burners.

here on the downdraft connexion…

actually we build a new gasifier with 14cm/nearly 6 inch ss pipe…

here some pictures of the inner design…instead of a grate we have built a kind of archimedes screw for ash cleanout from the reaction and reduction area.

the advantage is that i can also bring out slags, what would not go through a normal grate…this avoids complete emptying of the hopper to leave the slags…five turns and all ash , dust and slags is removed.

the new gasifier , design like koen van loken, is a hard nut to crack…

i tried now one nozzle, like koens, in updraft and downdraft…

also tried with 4 nozzles, also updraft and downdraft…

also with an excenter disc in the blower for light vibrations because of fuel flow…

bigger pieces and smaller pieces as charcoal fuel…

but i cannot get a good gas flare , for some moments is burning, than goes of, lightned again, burns for a short while and goes off again…

first i thought on hollow burns or fuel hang ups…so i made it with 4 nozzles how stefan abadessa made it…

but all the same…

now i think, maybe the reduction area becomes not hot enough because of the small diameter, for making good gas with a constant flare…

maybee a insulation around the reduction area could help?

who has experiences?

ciao giorgio

Hi George, small diameter has high heat loss so hot zone insulation would probably help a lot, and an even better effect would be achieved with a center nozzle, so the heat would be concentrated in the middle, I imagine installing from top to bottom so it would be possible correction of the distance from the nozzle to the grate, I have already made something similar and it produced good gas, but it cannot be compared to a gasifier on wood.

thanks tone , on the foto the first try with one nozzle, so i guess the fire glow ball would be in the center… left side is gas outlet (downdraft).

tried also without the perforated basket…

tried also in updraft…

i think also it is too much heat loss…will try with glasswool insulation around…

in what sense your gasifier in the video cannot be compared to a gasifier on wood?

by construction or gas efficiency?

the gasifier on the video runs with charcoal or woodchips?

you make a lot of really nice things!!!

always make pleasure to see it…and discover somewhere in the forum…as your tractor on woodgas!!! compliments… i am only a newbie …

ciao giorgio

Georgio did you also try a central nozzle in updraft? I believe that is how Koen does his small diameter gasifiers.

I think a central nozzle in downdraft will work well. Make sure to narrow the very tip of the nozzle slightly to add velocity to the incoming air. You can achieve this using a pipe plug with a hole drilled in the end that is slightly smaller than the pipe inner diameter. Or find a short piece of pipe that fits inside the nozzle pipe tightly.

Giorgio. Check these videos. I intend to do some experimentation with this stuff in the near future, thinking about making a fire tube with it packed between an inner and outer metal form so that went the inner metal eventually burns away it can be replaced with another sacrificial liner. Cheap and easy to make from readily available components. All the heat will stay inside the reactor.