actually we build a new gasifier with 14cm/nearly 6 inch ss pipe…

here some pictures of the inner design…instead of a grate we have built a kind of archimedes screw for ash cleanout from the reaction and reduction area.

the advantage is that i can also bring out slags, what would not go through a normal grate…this avoids complete emptying of the hopper to leave the slags…five turns and all ash , dust and slags is removed.

the new gasifier , design like koen van loken, is a hard nut to crack…

i tried now one nozzle, like koens, in updraft and downdraft…

also tried with 4 nozzles, also updraft and downdraft…

also with an excenter disc in the blower for light vibrations because of fuel flow…

bigger pieces and smaller pieces as charcoal fuel…

but i cannot get a good gas flare , for some moments is burning, than goes of, lightned again, burns for a short while and goes off again…

first i thought on hollow burns or fuel hang ups…so i made it with 4 nozzles how stefan abadessa made it…

but all the same…

now i think, maybe the reduction area becomes not hot enough because of the small diameter, for making good gas with a constant flare…

maybee a insulation around the reduction area could help?

who has experiences?

ciao giorgio

Hi George, small diameter has high heat loss so hot zone insulation would probably help a lot, and an even better effect would be achieved with a center nozzle, so the heat would be concentrated in the middle, I imagine installing from top to bottom so it would be possible correction of the distance from the nozzle to the grate, I have already made something similar and it produced good gas, but it cannot be compared to a gasifier on wood.

thanks tone , on the foto the first try with one nozzle, so i guess the fire glow ball would be in the center… left side is gas outlet (downdraft).

tried also without the perforated basket…

tried also in updraft…

i think also it is too much heat loss…will try with glasswool insulation around…

in what sense your gasifier in the video cannot be compared to a gasifier on wood?

by construction or gas efficiency?

the gasifier on the video runs with charcoal or woodchips?

you make a lot of really nice things!!!

always make pleasure to see it…and discover somewhere in the forum…as your tractor on woodgas!!! compliments… i am only a newbie …

ciao giorgio

Georgio did you also try a central nozzle in updraft? I believe that is how Koen does his small diameter gasifiers.

I think a central nozzle in downdraft will work well. Make sure to narrow the very tip of the nozzle slightly to add velocity to the incoming air. You can achieve this using a pipe plug with a hole drilled in the end that is slightly smaller than the pipe inner diameter. Or find a short piece of pipe that fits inside the nozzle pipe tightly.

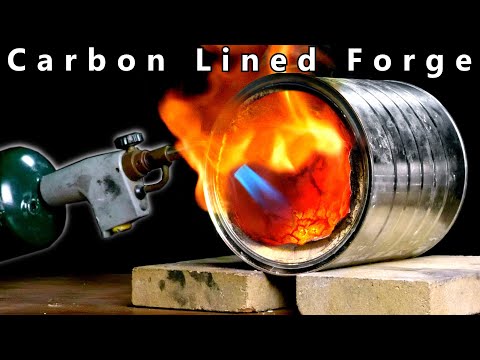

Giorgio. Check these videos. I intend to do some experimentation with this stuff in the near future, thinking about making a fire tube with it packed between an inner and outer metal form so that went the inner metal eventually burns away it can be replaced with another sacrificial liner. Cheap and easy to make from readily available components. All the heat will stay inside the reactor.

Hi Giorgio, you have probably already seen the published sketch of my charcoal gasifier with the nozzle down, I also added the addition of water vapor, which further improved the gas, but when I tested the gas from the wood chip gasifier, it is inappropriately more caloric. I do not understand the full operation of your gasifier, but I think the center nozzle placed above the perforated basket (approx. 10 cm higher directed downwards) would work and the gas outlet would be through the basket down. The basket itself would retain and reflect a lot of heat. The capture would be done through the upper side opening and a small opening added inside to capture steam from the top. I would add an extra wrap around the hot cone from a larger diameter pipe so the gas would create a layer of insulation and keep the heat.

Friend, otherwise I did not deserve such praise, my work is not worth it, I’m just trying to understand the process of gasification, … thank you for the kind words.

now the problem seems resolved…today we made a insulation with ash in italy outback style around the gasifier, and now it works well in updraft… 2 hours on 4 nozzles without interruption, always good gas , will say good shure fuel flow, without excenter disc (for vibrations) on the blower!

for downdraft not works because, obviously , how tone said, the reduction is too short…

koens small diameter gasifier though has no insulation…but he has a tropic climate, here in italy in the mountains is yet cold…

maybee when i have tried in summer , all would have worked well, and then in winter - a big mistery- it would not have worked more…

Hi Giorgio, I’m glad you succeeded, you work hard and make good progress, unlike me, who just stumbles on the spot and doesn’t move, my job steals all my best time, … and all my best years, … .I probably sound a little like Tom … but there must be some competition between the neighbors or not.

Giorgio, Keon V. is also using a bamboo charcoal very small in size. After every run it seems he dumps out what is left and puts in a new batch for the next cold start up.

Bob

Too bad we caint have some GOOD wood gas drag races some time at argos, they would probbly have too raise the addmissions for that weekend event too cover insurence. :smiling_face_with_three_hearts

hello bob, time ago i have contacted with koen…he told me about shure fuel flow : it depends a lot of the fuel size to have undisturbed fuel flow…vibrations , from a engine for example, can be helpful…

therefore i decided to try with 4 nozzles like stephen abadessa made his gasifiers…

to avoid a dusty clean out after every use, and to avoid “overheated” coal i try to go on downdraft system and cleaning out the ash and dust with the archimede-screw, shown in a upper foto…

ciao giorgio

gasflare in the night…

we tried a longer reduction zone for downdraft use…but it needs a lot more time for getting good gas…instead with updraft we got good gas in 5-6 minutes…this is a valid argument for using updraft system for cooking gas production.

when it becomes a every day task, it should not need too much time.

in our experiment we have seen that the insulation over the nozzles must be minimum 20 cm high…with 15cm height the gas sometimes was not good and goes off…we think because of not sufficient reduction heat

Giorgio, I’m trying to explain why the difference between the down process and the up process in gasification of charcoal. Upward process - air is blown into the charcoal which starts with oxidation, which gives heat to gasify the coal above this zone, the heat naturally radiates upwards and combustible gas is quickly formed, but the disadvantage of this process is that all the charcoal dries and the resulting gas is hydrogen free, CO only, and another drawback is the removal of ash from the firebox. The downward process takes longer to start, because the heat forces upwards, so a glowing zone is created more slowly under the nozzles, and Kristjan also complains about the initial start-up. The cross section of the nozzles is also an important factor, the smaller they are, the faster the glowing layer is formed but higher air pressure is required. Moisture rises under the cover and eventually descends into the reduction zone, forming hydrogen.

thanks tone for the explanation…my son also thought it depends on the heat that goes always upwards…for cooking use the starting time but must be short, so i will try now in the updraft, and see how the gas works on the cooker.

eventually, for avoid upheating in the hopper part , one could make the gas exit , let us say, 30 cm over the nozzles?

what do you think about?

what diameter has your green gasifier?

how much start up time to receive good gas?

ciao giorgio

The diameter is 20 cm, below is a narrowing to 10 cm, the nozzle has a diameter of 10 mm and is placed 10 cm above the narrowing, which is a little more than 10 cm long, so the distance from the nozzle to the grille is 20 cm. Starting takes about 5 minutes to make the gas combustible, it can drive a 450 cc 12 hp engine. Another thought, the nozzle pointing downwards pretty much prevents the hot gases from rising.

thanks tone for the fotos…the box beside is a dropbox for ash and dust?

for what you use the small metall pipes?

it is always a lot to learn from pictures of other constructions, a foto gallery would be nice on DOW…

i think your quick startup time in downdraft comes from the bigger diameter, so the heat has more charcoal around, and the metall cannot steal so much heat , as in my construction with 14cm diameter…

further i think your blower from the vacuum cleaner is more strong and heats up quicker…ours run with a little solar photovoltaik paneel, for me a advantage because off grid

ciao giorgio

Giorgio, below is a round ash pan, the gas rises through an angular tube welded to the wall of the gasifier through an angular water container that cools the gas. The copper pipe is installed inside the ash chamber, where there are two wrappers, here the hot gas gases heat and evaporate the water rising into an angular vessel, and the resulting steam is fed to the air supply for a stronger gas. I agree with you that starting with a vacuum cleaner is faster, I am now using a battery blower.

thanks tone, you are a artist!

you should make more threads of your builds…

ciao giorgio