Framiture overide for a barnswaggle

I am going to have to guess, it’s-a-I-don’t-know rusty valve.

a vacuum valve operated mixing valve, maybe for like a carburated diesel the size of a tank, or some industrial process. ![]()

PS. I am guessing fast and wrong, because I don’t want to spend a half hour trying to figure out what it actually is. ![]()

I,m lazy and it hurts when I think so I’ll wait till you tell us. ![]()

I think Sean is close, I think thermostat liquid cooled engine?

The cover with the broken off screw-bolts is a diaphragm chamber. Pressure signal passage visible on the “PATENTS” cover.

It plunges downward to the vertical round section just visible behind.

Is this connected to the lever arm on the TYP A24 housing? Unknown. I think not.

That lever rotating the insert inside of the the not-iron bell piece.

A flow/load demand control valve.

Steve unruh

With what looks like a diaphragm and possibly a cup and magnet speedometer mechanism, it might be a cruise control/speed control unit bigger than any I’ve ever seen. Either that, or it’s something else altogether ![]()

Edit: If it looks like a cruise control, I guess it could be a governor also.

water pump??or a pressure minimizer for water?

interesting your archeologic area …

And we have a Winnerrr: mr Cody ![]()

First, and the correct answer! Congratulations!

Others had good (and funny) suggestions too, Sean suggested a mixer valve, and SteveU described his conclusion in a “analytical” (?) way.

Well, this is a 1940 woodgas auto-mixer, patented by Baltzar von Platen, one of the inventors of the absorption refrigerator without mowing parts.

The lever is for coarse tuning of the mixer, for varying gas quality, it turns a brass cylinder inside the mixer, which changes the passageways for gas/air. The casted text, “gas”=gas, “luft”=air.

It is pretty rusted and cracked, but im going to restore it, when time is right.

I dug it out the ground under a collapsed wood-shed, after a tip it could be found there.

The other day i dug it out, Again, from my stuff, when looking for some vacuum gauges.

This is the air valve butterfly, it’s controlled by a 5" diaphragm, piped to the woodgas line.

This is the brass control cylinder, the rusted away flaps to the right is a “inverted propeller” which was added afterwards to help mixing gas and air better, by creating a swirl.

Ooops… a history lesson again? Sorry guy’s

So it is found afgain, in the Balthazar museum. Congrets Cody. ![]()

Oh geez, Don’t worry about the patent! Just draw it up in autocad, so we can 3d print it and cast one ourselves.

Goran you fox, you knew wich pictures to show that are not too revealing ![]() those last pictures are much more revealing. Wery interesting!

those last pictures are much more revealing. Wery interesting!

I’ve come to find out that resin 3D prints are fairly high temp rated. Some hot enough to cast lead into. Only issue is the extra HT versions are also brittle. Maybe a mixture of the “tough” aka flexible resins and the HT resins would work out.

If I was good(or even basically knowledgeable) at CAD I’d love to try out a 3d printed throttle body. Resin also is fluid tight which not all Filament prints can do easily.

They make a lost wax filament now but it is kind of expensive, or you can use PLA in a ‘lost wax casting’. I haven’t seen anyone try it with iron though.

FreeCAD is free. It take a few minutes or much longer to get your head wrapped around it. There various instructional videos on youtube and udemy has classes. You have to spend some time with it. But it is fairly full featured, and don’t expect to learn all the workbenches.

But even after you know it, you still have to sit and measure all the parts and pieces if you are going to copy something. But then it is at least documented.

Honestly, it would be worth your time to spend to learn FreeCAD. It is full featured, completely free, and it has a lot of high end features that are like ‘addons’ even in like autocad. It is good for both additive and subtractive, and you don’t have to own the equipment, there are people with services that you can outsource production to. And you are of the generation that will find a uses for it for a long long time.

Here is an article on the ten best ways to 3d print metal.

Well, I woke up after the nightshift and saw this

The pipes for the greenhouse arches are 2 3/4” od and all the bracing pipes are 1 1/2”, there must have been quite some weight on there.

Well, I guess I know what I have to do in spring, have a few ideas on how to solve it. I have four more complete arches lying in the barn unused and am thinking of using the barn wall as one side and have a half-circle down from there instead because I don’t think this is all salvageable to put up as it is now, and who’s to say this won’t happen again in a year or two.

Well, it is as it is and I am happy noone was in there.

Oh, nooo! ![]() I hope this doesn’t interfere with your gasifier construction schedule.

I hope this doesn’t interfere with your gasifier construction schedule.

No way, this won’t get work on it until the snow is gone. So there is time for gasification still ![]()

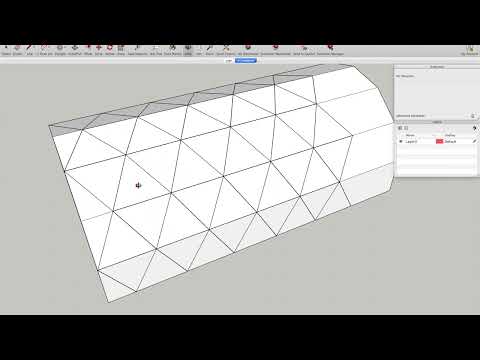

That’s a hard pill to swallow Johan. We have quite a few grow house set-ups in my area and this is a snow belt as well. A lot of them use a center beam the full length of the structure and posts about every third frame. Then a pipe to a purlin mid-way in the half arch like a peace sign. I built some geodesic domes in my hippie days and I am still a fan. If I were to build a tunnel I would do it like these designs from Paul Robinson’s site. I’m a fan of his as well.

Some videos about a similar situation. This guy had a whole aquaponic trout set-up in his. A couple of videos about him tearing is system down. pretty interesting. Snow is no joke. Building codes in our area require a 70 PSF snow load. I keep my house roof shoveled anytime is gets over 18 inches on it.