The lack of smoke coming from the wood when you look through the flames means that wood has a very low moisture content. Secondary air is added at the bottom of the blue shroud and meets the hot gasses coming off the wood allowing it to burn. There must be some combustion air that enters the area where the charcoal is augured out, travels down the pipe and up through the deep bed of charcoal to where the wood is burning. I am not sure why the charcoal does not burn down to the bottom??? fire moves toward the oxygen source. It looks like a system that needs constant attention. Like every 15 minutes. I like the auger removal. Not sure what the shut down procedure is. Is the shroud removed and a cap placed on the inner container?

Gary in PA

In the written description under the video, ( when watched on youtube) as i understand it, there is a set of holes somewhere a foot or so down in the inner drum, for primary air supply. So since air take path of least resistance…So, not unlike our gasifiers, the most heat is at the nozzles and the char falls down to fill the bottom and cools once below the air inlets. He hoses it down with water to shut down.

The descriptive text stolen from under the video:

.Design details: It is made out of a roughly 40 gallon propane turned vertical with the top cut off and a 60 gallon pressure tank with top and bottom cut off. The pressure tank is placed over the propane tank to act as a heat shroud. Air is drawn by convection from the bottom between the two tanks and travels toward the top. 9-10 inches from the top of the inner tank there is a series of 1" holes allowing some of the air into the inner tank under the wood, thus burning the wood. The rest of the air is allowed to escape out the top between the two tanks, thus supplying the secondary air to burn off the smoke. The coals that form fill the center tank and are gradually lowered down as the charcoal on the bottom is augered out. As the coals are lowered they drop below the holes where the air is introduced. Thus, deprived of O2, they too cool off by the time they are augered out of the bottom of the center tank.

It looks like you have to fill it first with charcoal to start it up, then put wood on top of the charcoal. Just like starting up a Gasifier for the first time.

Bob

Thanks Andy, I did not look below the video for a description. Glad you noticed it and posted. That system will surely work. But as noted, you have to fill it with charcoal to get it started. Not a bad design, just needs constant feeding.

Gary

Hello,

I really like the idea to use the heat from the charcoal making process for something useful, e.g. space or water heating. A good example is Gary Gilmore’s Keystone stove.

A very good combination would be be a combination of the retort shown in post #147 and something like the keystone stove.

Btw, here are more pictures of the continuous charcoal retort: Making charcoal continuously - #7 by freedombiomass

Regards,

Tilman

I did another test on my horizontal retort the other day - after adding a section of ducting to try and capture the steam/smoke produced at startup. Here is a video of it as it is starting to produce smoke.

I still had a difficult time getting it up to speed in a reasonable amount of time: It was venting smoke within half an hour, but it took over 2 hours from lighting it to get flammable gas coming out of the vent and lower jet.

I got new batteries for my luggage scale and got pretty exact values for how much wood I used. 120.5# went into the drum, and 22.25# were needed to stoke the fire. I got 28.5# of really dense and nice charcoal, which accounting for moisture, gives me a conversion of about 24%.

My conclusion at this point is that this style of retort is not well suited to using only a passive draft. The small cross section of the firebox means that once the wood burns down into coals, you block the airflow so much that the heat transfer into the drum slows to a crawl. I am going to have to try it again with some sort of blower fan and see if I can get the start-up burn time down under an hour. The smoke catcher works fairly well, and it is possible to adjust the pressure inside the drum a little bit by covering only part of the steam valve. Some smoke still leaks around the lid.

I am going to work on the fan, but also try out a much simpler design such as the TLUD with a passive draft and afterburner. I will record some weight data for that method and see what I come up with.

Hi Carl,

watching your video it came to my mind that if you would attach your rectangular flue directly and sealed to you chimney, you should get a much better draft. Maybe you don’t need a fan in this case.

I think it is worth a try.

I have experienced things like this with a test run of an old oven. Different burning behaviour with and without a airtight connected chimney.

Hope this is helpful.

Regards, Til

Hi oregoncarl,

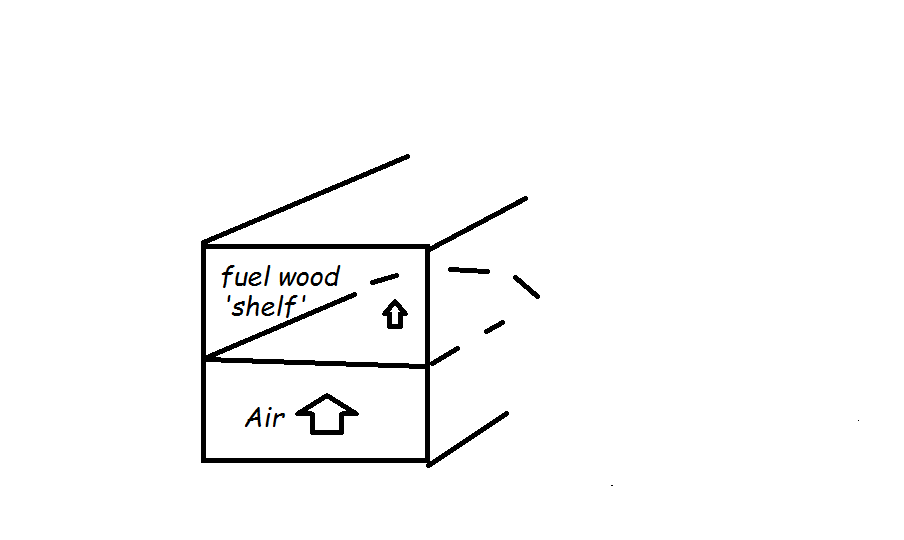

I’ll just throw in my 2 cents worth from my ‘gasifier wannabe armchair’. Try a ‘coals hold’ type thing, that will keep a good amount of your ash, coals, and fuel out of the burn tunnel. I believe this little box could be made of the same square tubing your already using, you could even throw in a grate at some point when it suits ya.

Maybe my picture will make it somewhat clear what a ‘coals hold’ might look like.Oliver

Hey Oliver, This was another idea I had kicked around as a possible solution, and I think it could work. The biggest complication is how it mounts to the existing burn tunnel without getting in the way of removing the barrel lid. It almost has to just slip on and off, or else it could be bolted onto the lid itself somehow. I do like that in theory this should allow me to stick with a passive airflow, which is a big plus for me, as there is no electrical outlet within about 400 feet. Also, I suspect it might allow me to burn slightly bigger wood, and not have to babysit the retort as much.

I am inspired, I think I will add this to my list of things to work on. Once I am done with this retort it is going to look like an oil refinery with all the chimneys and pipes and what-have-yous, but … in for a penny… Not sure when exactly i will get too it, as we are having a week of gorgeous weather, and I feel like I need to get so many little projects taken care of! I am hoping to test my upgraded micro-hydro setup tomorrow, which will be nice to cross off the to-do list.

Carl, I’m sure enjoying this topic and your good work. Since the electric is 400 feet away, maybe you can find a cheap cordless leaf blower to rev things up a bit in your blast tube. If you decide to go with a TLUD, you will find that a little fan assist on the air inlet will do wonders for performance.

A modest chimney should address the draft and performance of a TLUD.

Chimney draft effect can’t be discounted on any system, potential major free boost, arguably transforming waste heat into direct mechanical draft, improving system efficiency.

Hi oregoncarl, both Southerland and Tait make valid points, getting the heat value UP, quickly & sustained, I think you need to see your fuel wood white hot, not yellow, then back the blower down if your apparatus is melting or something. OK 400 ft. …no problem!!! … DON’T DO THIS: can you find one of those ‘cyclone attic vents’ they are going to suck like crazy on top of your chimney…rofl OMG. Ya it would be nice if you can find a steel one, on account of alum. is going to fail…but you could 5X the draw with a cyclone. And yes, it is AGAINST THE LAW TO FIX A CYCLONE UPON A CHIMNEY—JUST SAYING! you will need a brake of some kind to lock it down as things get thrilling, a much longer chimney, [not necessarily vertical] might get some of the intense heat off of the cyclone, because the heat rolling thru it is going drive it hard!, probably moreso than your average prevailing winds…or just get an extension cord, ummmm most refineries has an extension cord stretched out…hahaha! Maybe on the ‘coals hold’ thing, make it where it will slip fit the tunnel and just be a free standing thing separate from the lid, give it some legs and a heavy chunk of firewood to hold it against the lid. Heck I don’t know, did I mention I’m just an armchair wannabe, I know not if any of this stuff will work for sure for sure.Untitled2|690x412

One other approach to the burn tunnel clogging…try a piece of sturdy steel mesh or plate in your burn tunnel, it becomes a ‘shelf’, load your sticks upon that thing, allowing ash to fall down thru it, and easily scraped out with a crooked stick. Maybe my pix will make it clear what I’m trying to say.[

This our giant kiln, we named it THE BEAST, it´s big. The drawing is this this:

I hope it can be understandable-

It looks pretty good to me. It just needs a moisture vent out through the back or up through the top. Once the moisture is driven off and the gas will light, close the vent with a valve or cap to force flammable gas down to the burner. A little insulation on the door/lid would also help.

The diagram shows adobe bricks for the walls, but I couldn’t make out what it says the floor consists of.

Good design.

From videos that I have seen, once retort gas is produced, there will be more than enough to maintain the reaction. If all of it is burnt below it will probably lead to destructive temperatures. It might be good to think of diverting some for drying or other purposes, possibly heating water? But how much hot water is useful?

Hello Abner,

Your diagram shows brick kiln surrounding the steel charcoal vessel, will you consider the brick roof, perhaps as an arched roof? A flat brick roof is very heavy, difficult to support as the unit becomes very hot, a flat brick roof is subject to cave in easily & difficult to build.

I am unclear about something, will you intend to fill the area between the steel charcoal vessel & the brick kiln as a combustion chamber? Filling between the walls of the brick and the steel vessel, with biomass to bake the contents within the steel vessel, to make charcoal is that what you intend?

I like your steel manifold.

Oliver

I know i have spoken about how i am doing my charcoal at the moment and i will update on that in a moment , but one thing i do remember from early playing of the rocket stove type fires was a few years ago i tried to make a pizza oven rocket stove ,it was a rocket tube going up to a barrel within a barrel and sealed with insulation and so thought it would be fantastic and quick , well nearly 40 or 50 min after lighting i got a nearly cooked pizza , after much head scratching and playing it came down to just one thing , the size of the burn tube was too small , it was 4 inch square tube and for some reason just had a limit and that was it no way would it get hotter unless you used forced air .

So this year i had 2 very large mountain ash gum tree’s taken down in my garden part of the deal was they could leave all the branches and i would do those as long as they cut the trunks into manageable round for me to split , so i needed a way to use these branches up before the fire season hits us . Eucalyptus leaf’s are the most frighting thing i have seen once burning its like holding a cup of petrol on each twig as it burns , so decided to go ahead and make a Hookway design type of retort using a 55 gallon drum with a 4 inch round flue pipe through the middle and out of the side at the top of the drum, , again my mistake it should have been 6 inch flue pipe , but i used what i had to hand and this drum just sits on steel plate with a hole in the middle that matches up with the hole in the drum and under the plate i dug away the earth and light my fire there , if the pipe was larger then even more of the fire from below would get drawn up and through the barrel , as it is if the flames get too high they just allow as much as they can to pass through barrel and the rest go up the outside this is how i make a drum of charcoal with pretty good results and very little loss in volume , and ALL of the branches that are cut up to around 6 inches long and range from half inch to 4 inches in diameter , i see a small amount of steam coming from below where the slits are in the 4 inch flue pipe , and when it does start to smoke as long as there is plenty of air flowing through it tends to set alight and then once fully gassing it makes a lovely flare stack on the top of the chimney ., when i get through all this green stuff i want to see how much better it does dry wood , btw because i am trying to burn the leaf’s and the smaller branches ,under half inch its a long process as the gum leafs themself make some black smoke so i only bur 1 branch at a time and so my drum of charcoal can take 2 or 3 hours in hand

feed burn time before it will self burn .and then thats about 1 hour .

Dave

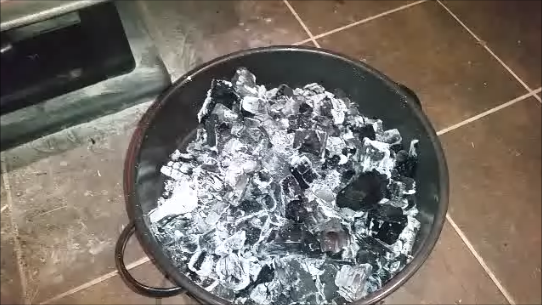

It was -27 C this morning and a balmy -20C right now so its a perfect evening for making char. I’ll have to stop soon as the house is at 23 C and getting too hot! I do want to build an outdoor boiler like my friend Wyatt and make barrels worth of char but here is a nice easy way to generate 5 to 10 gallons of engine grade char a day with no special build while maintaining good heat harvesting.

Cheers, David

Here is a link to the video

And some pics for the dial up crowd

Ha, l skrach every bit of char l can get too now. Includeing my outside boiler. Its not exactly good at char production as it gets all its air trugh the grid on the bottom, burning the char, but l found leaving some ash in to plug the grid will boost char production.

![YU3g4BJBfb56JJ2X0fa1g8U6[1]](/uploads/default/optimized/3X/1/6/164bf72f1c7703d71c91f9f9ff4ba171223aa395_2_596x500.jpg)