Hi there y’all! I am new here but not new to the idea of wood chunkers and chippers.

If you think this post is too long, feel free to scroll to just above the first picture where it says Tl;dr ![]() If not I found it really helpful to write down my thoughts, so thanks in advance!

If not I found it really helpful to write down my thoughts, so thanks in advance!

I have had the dream to build my own woodchipper and chunker since about 2017. The reason being that this is about the time we started thinking of moving to the countryside in Greece from the Netherlands. The concept has gone through several iterations in my head and sketchbook, refining it as I found parts and new ideas. I am actually grateful for this project getting postponed for so long because it has allowed me to mature as a maker and get it right the first time. Also I speak decent Greek now. Enough to communicate with a machinist. I would have made some big mistakes if I had executed on version 1.0 ![]()

We made the move in late 2018 and have about 30 olive trees on our 3000m2 / 0.7 acres and I am now at a point where I am landing jobs to prune and harvest other peoples’ trees as well as maintaining our own. I am a permaculture designer and don’t really agree with the current ‘standard operating procedure’ around pruning and harvesting the olives. Which is mostly to just cut them hard, save the bigger branches for firewood and burn the rest in giant piles. Or dump it on the side of the road somewhere for the council to clean up.

- I see a LOT of unused resources there.

- I see piles and piles of woodchips for feeding the soil of our growing food forest and a swale of 90 meters / yards. We can capture up to 160.000 liters of water in these earthworks (42.000 gallons?). And it fully fills up about once a year it seems. It partly fills up a few other times. The water then infiltrates over the next few days.

- I see firewood for our Rocket Mass Heater, because unlike fireplaces, our heater runs fine on branches of an inch or even smaller.

- I see coathangers, lampshades, table lamps, doorhandles and other things in all the curvy, weird branches that come off of the olive tree. Its an amazing wood for artistic stuff like that.

- I see employment in doing this work RIGHT because a lot of people (not everyone) just chop the trees very roughly without proper pruning methods and yields can drop for years.

Anyways, enough about my reasons for wanting something like that, let’s move onto what components I have already gathered.

- I own a Bertolini 310S two wheel tractor (I have a playlist for it on my youtube channel). It is powered by a 12hp 500cc (30cu?) single cylinder diesel engine by Lombardini (BLD510n - 1985). It is a BEAST. I have handled a few small implements like that, mostly gas ones. All of them feel like toys after working with this machine. And like you can imagine, very simple and reliable. A simple rotation until you reach the compression stroke, wrap it with a 1.3m cord, set it for manual start and pull the cord. I very rarely have to pull twice; though it doesn’t get cold enough here to freeze outdoor copper pipes. No electrics or battery to go bad. If you wanna see something cool, check out this video.

- I own an industrial strength reducer, all steel and cast iron. Needs three people to lift it. The ratio is 8 to 1.

- Over the years I have gathered a couple of different pulleys, axles, bearings and stuff to make everything come together.

- I bought two cutting heads out of a ‘silent garden chipper’. These will work to chip the smallest stuff into woodchips using torque rather than momentum.

Ο Κάστορας / O Kástoras (The Beaver in Greek ;))

I hope to make a device that is mounted behind the tractor, but instead of it being a rotortiller, it is a wood processing machine. It will have a woodchipper and a spiral chunker. I intend for it to be much smaller than most chunkers, the thickest branch I imagine cutting would be like two inches of fresh olive wood.

The massive reducer would reduce the PTO speed from about 500RPM to 60rpm, so one full rotation of the axle per second. I believe the outer edge of the chunker would rotate slower due to it being further away from the central axis (??). Further reduction is possible using different sized pulleys if need be. I have designed everything so the pulleys and chunker blade are replaceable. The torque coming out of that reducer should be insane. Plenty of power to run everything I have in mind.

I intend to drive everything through V-belts because it protects the wormgear in the reducer. I only have one, it was quite expensive and I want it to outlast me. The belt drive system will effectively act like a sheer-pin. Instead of the irreplaceable wormgears being torn to shreds in case of failure, I might have to replace some rubber belts. Also it allows me to place the ‘working axle’ at a comfortable work height whilst the massive weight of the base and reducer are as close to the ground as possible. Lastly I will leave the belts kind of loose and add a ‘clutch’ to engage the ‘work axle’. I didn’t draw that.

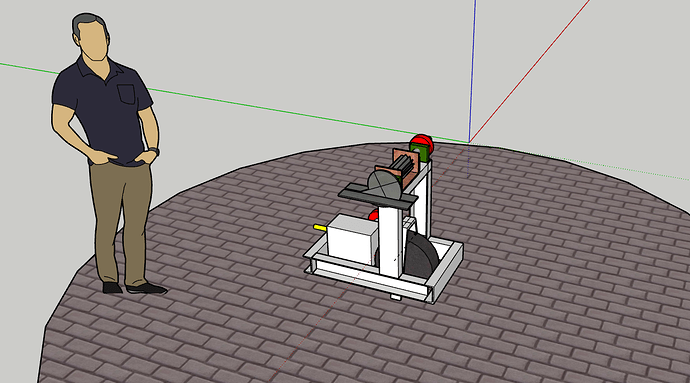

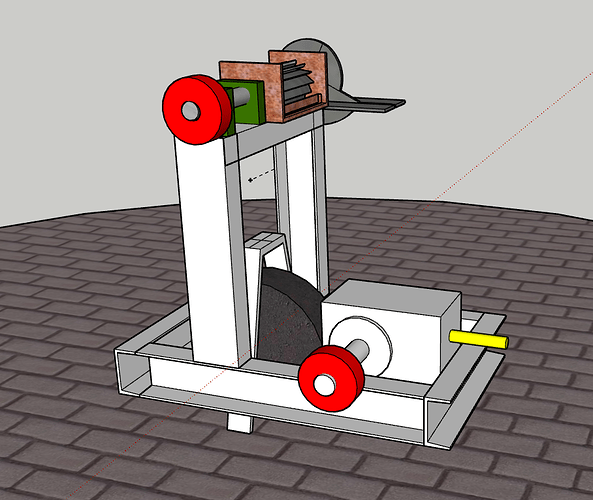

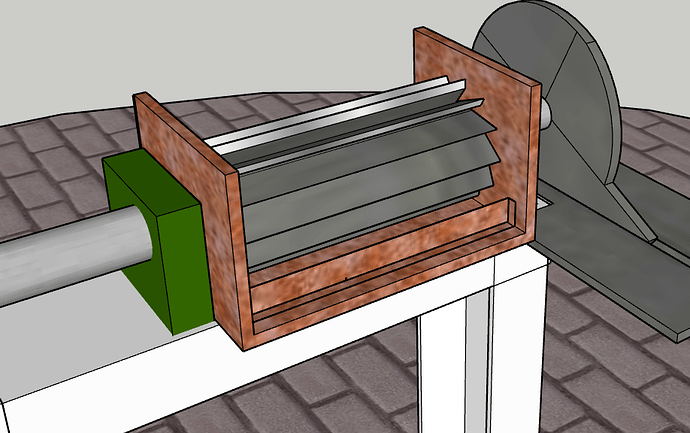

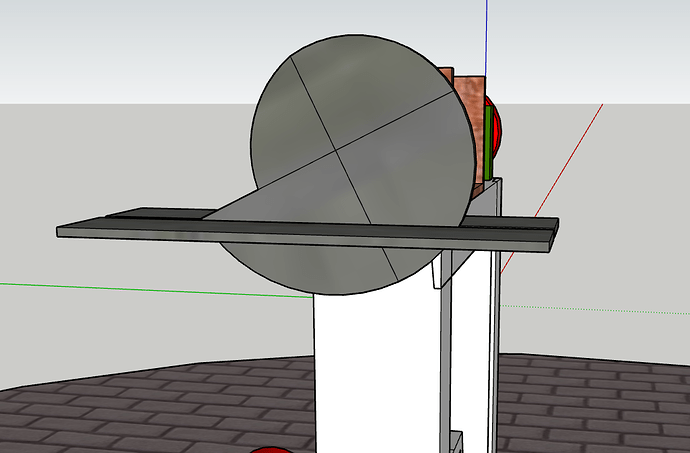

Below are some pictures of a model I made in sketchup. I am not great at sketchup but I hope it will help communicate what I have in mind.

Tl;dr? I want this kind of chipper and this kind of chunker, mounted on the same axle.

The yellow axle will attach directly to the PTO of the tractor using the standard PTO coupling. The white box sitting at the bottom is the Reducer, which transfers the motion to a 50mm shaft; this shaft sits at 90 degrees to the original rotation of the PTO. That black wheel in the middle is an airless wheelbarrow wheel and will allow me to steer (it’s a two wheel tractor, the back wheel will swivel from left to right). The two red circles are the pulleys which will use three V-belts to transfer the energy from the Reducer to the Axle. The green boxes represent bearings, the chipper is in a brown metal box, the chunker on a grey metal platform.

Other side of the device, showing the pulleys.

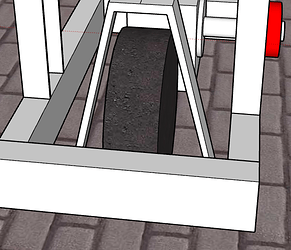

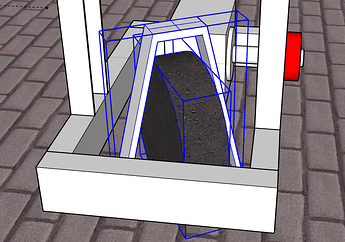

Below are two pictures of the steering wheel, it will be attached with an axle going straight up and through two bearings. I will add a steering wheel to that, which I haven’t drawn here.

The chipper. Branches will be pulled into this and come out as very fine mulch on the other end. One of my biggest frustrations with woodchippers is when you have to push the material into it. Obviously this box would be enclosed and have some kind of chute on it.

The chunker. This will be used to cut the firewood out of the branches and in the same motion throw the ‘leftovers’ into the chipper.

That’s it! Now I would like to open it up to feedback.

Specifically about that axle. Right now the chipper blades have an internal diameter of 32mm (see the pictures below). I am planning to buy a 35mm axle and ask the machinist to turn it down to 30mm, allowing me to fit the bearings I want.

Is 30mm / 1.18 inch thick enough for what I want to do?

What do you think about mounting the chunker at the end of the axle like that?

Anything I am overlooking?

Thanks for your attention and I look forward to your feedback!