How much does the second core gain you? Is it an efficiency boost, or just a performance boost? I didn’t realize they were stacked on top of each other like that. It is interesting in itself.

are you adding air in the second stage or is it just burning up what is left of the O2? Is it significantly less tar? I noticed on your other system, you are just using a cyclone and no media filter.

So, air intake above the reaction chamber with a restriction to maybe help trap the air from back flowing?

I suspect you are getting a semi-water gas shift reaction in the lower chamber which explains the lack of condensate, and the slightly better efficiency and lower temp. It is staying hot enough to crack tars in the upper chamber more like stephen’s victoria or the Drizzler with a fast pyrolysis. Then in the lower chamber you would have more pure carbon for the water shift.

I kind of wonder if both the air inlets are acting as a buffer for the uneven air pull by the engine thus you aren’t seeing heat and smoke up in the hopper,

It is definitely something to ponder and well worth the time exploring. It might actually work with more uneven materials, or you might try to bump up the humidity of the inlet air going into the lower chamber.

It really sounds like you are on to something though.

This 2 reactor thing is / are actual 2 gasifiers in one

The top one is making charcoal and burning all the tar’s down into gasses,

The lower one is a charcoal gasifier that converts/reduces all the gasses into “syngas” cracking all the leftovers from Tar

I think if a Co2 meter is connected, that your gas has a low Co2 content and low moister…

Congrats on your build and welcome the newborn…

now you have a build and need to find the theory behind it ?

now you have a build and need to find the theory behind it ?

Which one you’ll bring to Argos ? i crave to see some of your craftmanship

Im planning on that one for sure. Im going to try and build the automation systems for it. If I can Id like to get a new Evolution Mini SS built to also bring. But might keep it light this year

Yeah, I think we have the theory, we are all on the right track. I think this is major step in design evolution.

Oh, you are right! I though it was reading like 1500 degrees on the top one, but it is reading 150.0. I missed the decimal. I watched the video like 10 times before I noticed that. i couldn’t figure out why what you were saying and what I was seeing were two different things. But that was totally my mistake.

It is basically a closed top drizzler. you have enough space between the inlet and the wood/char to not burn up the nozzle. It keeps the air gap because of the top restriction, and it can’t fill up the bottom completely with pellets because they don’t flow freely and self-level.

Shaking it too much may cause it to level a bit, and you would lose some of the airflow gap. So you may need to extend the top inlet down a little bit, or add a chamber to the top of the bottom piece it attaches to.

I am not sure you -need- two chambers but it might be balancing some of the air pressure, and it is pre-heating/drying prior to entry into the second chamber. Did it help protect the fire from running up into the hopper without intervention?

I would try the cheaper softwood pellets in it, and see if you get similar results. The high ash for clinkers/bridging and I would guess higher tar would be a good challenge for it.

Hello Matt,

I am admiring your seriousness in your work, it includes a documentation on the same process that you test, the small passage between the two reactors, you will get a better result than xylowatt, which they, a passage too important, it is important that you send air in the second part, but it requires electronic management for good result.

Just for -that- it is totally worth having the 2 chambers. I was thinking you might be able have the 2 air inlets but skip the top chamber and reduce material costs. But it isn’t worth even testing if the second one stops the hopper from catching on fire.

seen that one before… remarkable… how similar minded people find similar examples…

Yup that is basically my original concept, I agree 100% on controlling the lower and thought of that to sustain the upper. But what Im seeing now and the way it it is working; with the absence of the hopper gases Im happy with the way it is working this way. Less complicated and the outcome is still the same of what I was trying to achieve with it.

Now I got to come up with smarty pants terminology for this reactor. The upper isnt really a reactor distillation Chamber?

Looking forward to seeing this up and running making wood chips to wood pellets for fuel, it is the main reason I have stayed away from a pellet gasifier, you had to buy the pellets. Might as well buy dino fuel. Well not really but close.

Bob

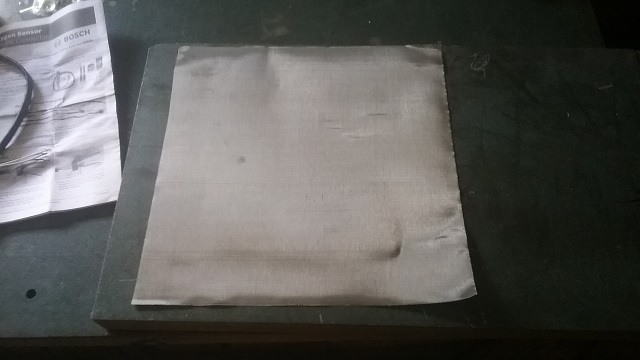

Looky what showed up today!!

This is 45 thou nickle screen for the Sabatier Reactor I will be experimenting with soon.

Are you tapping into your septic tank gasses?

No thats not how this reactor works. It uses engine exhaust gases and mix with the H in the gas to make CH4

You might be getting some shift already if you are using Stainless Steel. Honestly, I would think about wrapping it on the inside of the firetube, like just roll it up and let it spring back tightly against the tube. then put a clip or something to kind of hold it in place.