Ok thanks Matt, i should know you had all the basics covered, keep those model designs inprovments posting, I need too build a hopper shaker on my next design machine too be better able too run smaller lighter wood. nice work.

So took the day off from the shop to work on next generation design work. Now that the Flex Power System is nearing its completion of development I will start new development on a different type of system. The FPS will have its own market and this will fit a different type of market.

This new system will be a hybrid system featuring a built in oven, two cook top surfaces, built in hot water heater, potential evap system for refrigeration, heater mode with forced air fans TEG technology ready and did I mention it can run a power generator too?!!

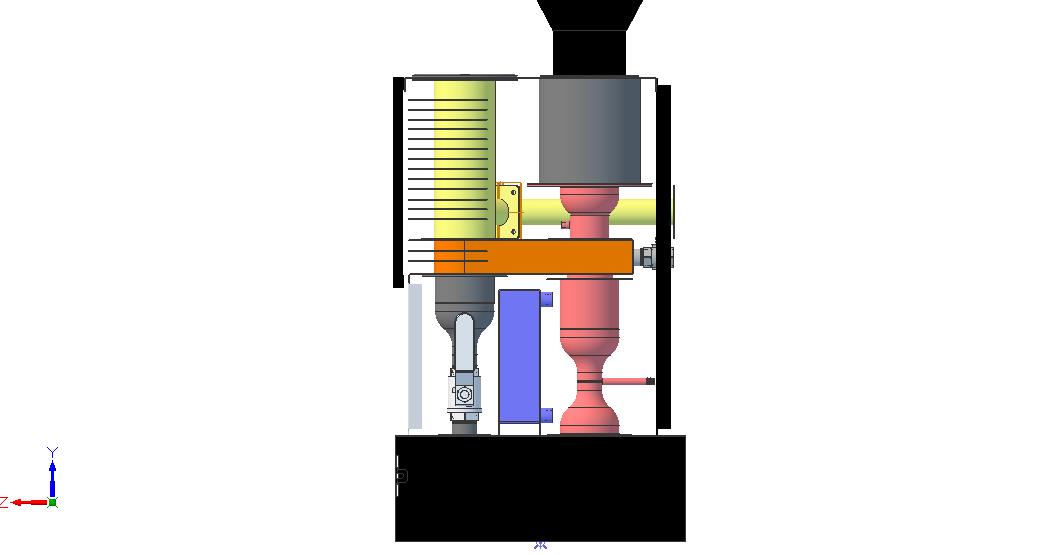

Ok so yeah this thing is going to be the works and will have implemented every idea and concept Ive come up with over the years. Because my reactor does not emit combustion gases into the hopper; this technology is capable of being installed indoors. If fact my stove from last year is a modified version of the Flex Power Systems reactor. However on this version it will have a full reduction core requiring artificial draft support so no chimney on this one. .There will be an outdoor DC generator system that will house this draft blower.

In heating / cook modes this will have an intake on/off secondary air intake to inject air into the gas stream as it leaves the reactor. This will have the charcoal secondary unit as well. So the glowing ambers will light the gas here. As the gas burns it will enter a cyclone that in this mode will double as a swirl burner for a complete burn. From here the gas is directed to the primary burner plate,then too the oven and then over the second lower temp burner plate. Under this burner plate will be a hot water heat exchanger circulate the home installed hot water heater. The draft blower will have a speed to control along with the forced air fans. In cook mode you will not want those forced air fans on and may want to intensify the heat output by cranking up the draft blower.

There will be two steam reformers one at the charcoal unit to control temp and also at the upper section of the top reactors reduction zone. Steam will go through multiple stages of heating before entering into process.

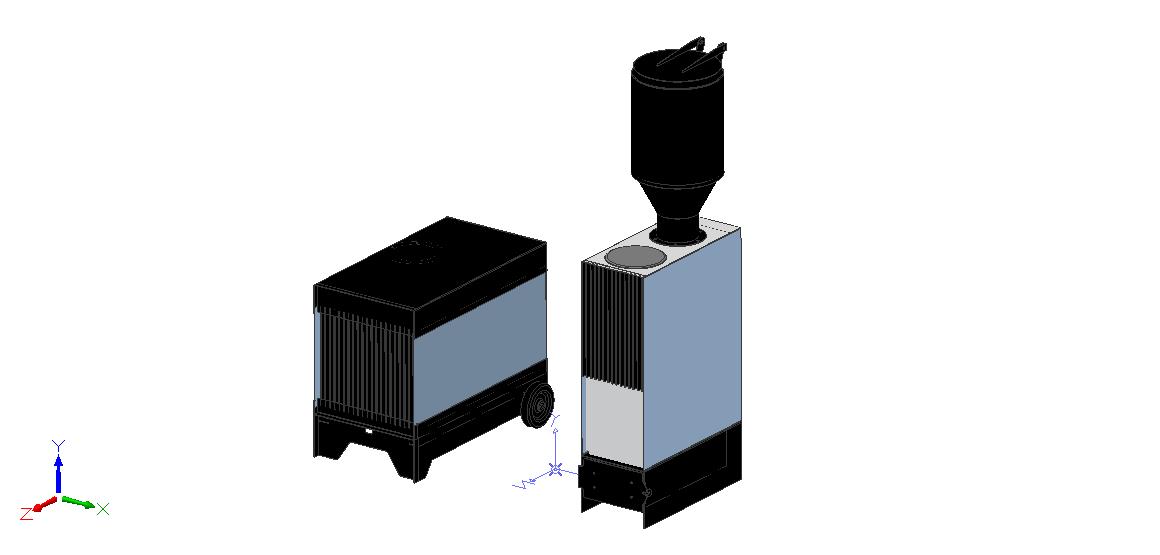

In power generation mode the secondary air intake is simply shut off and the gas will take the same path out to the outdoor unit. Here the gas may go through additional filtration and then directed into the engine just as we do now. However this will be a direct coupled DC 200 or greater amp alternator system to direct charge into the battery bank. There is a reason for this besides being DC direct from generator . This allows to run at lower more reserved rpms or it can be cranked up when needed.

Both units will be fully automated along with a remote thermostat. This thermostat could be used to control

heating mode vs power generation mode. .When the room gets too hot it could switch to power generation mode and run cooler while it is producing power. The it can switch back when the thermostat calls for heat again. Should be a very clever system. All systems will use blue tooth communication so no wires.

This could house quite few teg modules as well, could potentially get another 500 to 800 watts here.

Eliminate the hot water heater and refrigeration power requirement will add into over all efficiency requiring much less power production.

This unit if realized will fit the existing stove market stand alone and then will create market awareness as some learn its full capabilities. It would also be EPA exempt as it is a cook stove and not a heating device. So I could bring this to market fairly quickly. But this will undergoes a development process with only beta units available for the first year or so.

To be honest Matt I am not following on everything you are saying here, but I am sure I will pick up on it as you move along on this new project. I give you 100 plus likes, and thumbs up.

Bob

It might be a cooking device by the EPA, but it may need a chimney according to building/fire codes. It probably needs it to be UL listed appliance for insurance purposes. Wood boilers are popular because they use outbuildings, that typically aren’t insured. Thus you avoid the extra insurance costs for an indoor wood heating which have gone through the roof. I don’t think all of them are attached to the ground either, so property taxes aren’t affected either.

Don’t get me wrong. I think it is a intriguing and useful concept.

Why would it need a chimney, it will be a great deal safer with a draft blower.

Yes it will need UL listing but you dont need it to sell.

It will most likely need/want an exhaust vent. Once you start adding other things like hot water, it produces more of the gases that you don’t want in your house.

You are correct, you don’t need UL listing for it to sell it. However to get your place insured and actually covered, it very well could require UL listing.

I dont think you are grasping the concept, it has an exhaust that is piped thru wall to an out door draft blower. This will be built into the outdoor generator system. A chimney draft will not be strong enough as this is a full blown engine grade gasifier. The hot water heater will be coil in circuit of the house hot water heater.

You are correct. I didn’t understand the venting.

It would probably help if I could write more clear as well.

MattR I think your name “Thrive Off Grid” says most all needed to know.

All of my true electrical wood-for-power is intentionally done Off-grid to my equipment/farm sheds.

Then no insurances, no certifications needed.

MY power. MY risks.

True off-gridders assume their own responsibilities. Want beholding to as few as possible. Limited by as few as possible.

Will not want hand holding; and want the lowest risk-management run-up costs folded-in as possible.

You will succeed as you keep refining down your user base to practical using people.

Regards

Steve unruh

given your recent experimental mood, I wanted to chime in with an idea that I’ve had kicking around for a while:

A diesel particulate filter (catalyst style), mounted relatively close to the gasifier outlet (before or after cyclone, not sure). Perhaps with a bypass path around it for cleanouts. Goal: evaluation for particulate reduction, but also potential for cracking of heavier compounds.

it’s something I’m going to experiment with soon, if no red flags appear.

Hi Matt,

Have you decided what teg modules you are going to use and found a good source for them? I want to invest some time this winter playing with a homebuilt assembly. I want some good ones but don’t want to get hosed on pricing.

Thanks, David

No not really, the best I found was on Alibaba and I still could not get pricing that would make it viable. However, Im leaving the options open to at least employing a couple hundred watts. That may be doable to supplement the genny power or supply its own power for automation.

Im going to focus on the battery technology, just have not had the time to work on it. But I will soon.

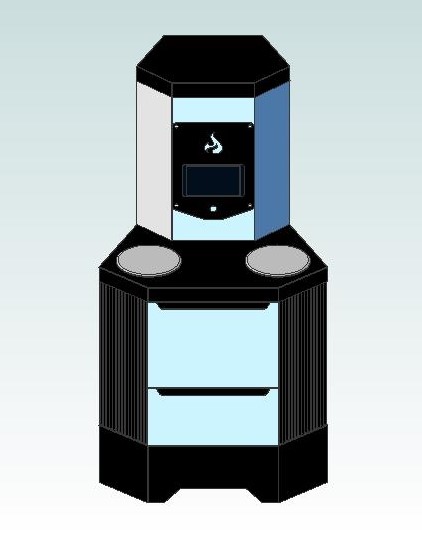

So Ive taken a more reserved approach with the hybrid system and scaled it down a bit. However it still packs a lot of features. I managed to cram the hot water heater, a single burner plate, the hybrid heater mode, dual reactor set up and steam reformer with a 1 gallon capacity. The hopper will hold roughly 1 1/2 cubic feet of fuel. Not quite a full 40 lb bag of pellets.

It has a foot print of 10" wide X 22" deep and the top of the hopper is 60 inches from the floor. It will have 7 inch forced air fan to distribute heat out in both engine or heater modes. The heat exchange fins probably wont make it on the production version unless we can get them laser cut. The first ones will probably have about half what I have shown here in the model.

This will have mild automation standard, (grate / hopper agitators) and then the full auto systems I current have developed but with out touch screen. Input will be single button input. It will change colors and pulse blink for interactive controls. Touch screen may come later if I can figure out where to put it.

Beta kits and full builds will be available after this first build. I hope to start building here in the next few weeks.

If successful, this will take the place of the stand alone systems and will better justify price point as it will double as a heater / cooking system. Much more marketable and stoves are getting more expensive so it will be on par with current market price points of systems of higher caliber.

So the concept has deepened!! Im going create a full product line of the VersaFire Gasifier/Pellet stove. This will be a different approach from previous systems. So instead of building the entire gasifier system complete with filtration, draft blower, etc. This will be done in modules; I will need to revamp the design just slightly so that it can except additional modules to directly bolt to it like Legos.

So for instance the VersaFire gasifier module will be the back bone of the system. It is just the basic gasifier portion with no filtration other than the cyclone / swirl burner. In a heating mode this will not be able to fully shed all its available heat. So I can then add on an additional heat exchange module in the same form factor with a forced air blower. Another version could offer a second or third hot plate or maybe a small griddle. Another option will be an oven with griddle with combined additional heat exchanger. Then there is the option where we could combine multiple stove units together for larger applications. Then you would have both heat and power on demand and also could potentially run larger engines.

Here is the first purpose built generator. I will be building this proto type starting hopefully tomorrow. This will be a more modest 1 kW output running an HF 79cc engine. The VersaFire shares the same exact reactor technology as the FPS system so we will see what range it has and if can run this tiny little engine with some de-tuning. If not I still have that turbo  I plan to expand this to a full line of small generators ranging 1 to 2.5 kW DC output and then the larger versions will shift to AC power heads. Probably wont go much larger than the 400 cc as hopper fuel capacity will be an issue.

I plan to expand this to a full line of small generators ranging 1 to 2.5 kW DC output and then the larger versions will shift to AC power heads. Probably wont go much larger than the 400 cc as hopper fuel capacity will be an issue.

New cam installed and the machine is back up and running. Going run more test tonight and tomorrow and we go live at 2 pm on Sunday.

So the live demo went well!! I was able to point a camera at the machine and I dont think it even noticed!!! lol.

There was a point where something happened, automation either went too long before agitation or it was too much for what ever was going on inside reactor. The automated mixer control was a bit slow to recover but it did the job. The machine ran pretty solid after that. I had a 3 kW load on it the whole time. Two heaters plus the lights in the shop and anything else plugged in. So it was more like a tad bit more than 3 kW.

My cell has seen better days so video quality was not so good. But the live feed was successful in showing this machines stability and ease of use. I wish I would have shown the condesate drop from the dryers, I now know that if the second one drops anything this is a telling sign gas quality was not so good. If nothing drops and only condensate drops from the first one this is telling us we have made very good and powerful gas.

The best part I was able to capture the powerful sound of that Kohler V Twin. Sorry for my crazy dog

Hi Matt,

Cyclones are a pretty effective means of removing particulate

matter from the initial hot flow stream. Step 1. clean up the gas

with the cyclone before it gets to the critical, expensive, hard to find

or get parts for item.

Then your step 2, imho. Pepe

Ive found I dont need them pre cooler anymore. The coolers self clean when the system is working right so no need for them. The scrubber unit gets rid of all solid particulates that make it past this, along with any ready to drop soots and then the cyclone dryers whip out any remaining moisture from the scrubber unit. Those cyclones are very effective at this best Ive found in 8 years of development.

This filter system is for the most part maintenance free other than draining it. The marble bed Ive cleaned it out two times and it didnt really even need it in four months of testing.

Dont forget I do have a CNC and I no longer roll cones. Those filters are just straight rolled cans, so they are fairly easy to make.

Yes if you were to get a close up of this machine, you will see how integrated it is from a manufacturing perspective. The geometry of this machine is shared over and over and over again vs older systems were just about every individual part was very unique. The comer vessels all have their own unique function but they all share the same physical geometry. This allows for one fixture system to build all of them. Same goes for the layered sections. This machine out of any is probably the closest to modern manufacturing level where it could be built with out hands on labor intensive set ups and so forth. The four pillar design eliminates the need to build an enclosure as the gasifier system itself becomes this structure. .Just add the panels. Plus these corners are thick aiding in the sound reduction.

The simple ideas are the hardest ones to come by