And the most valuable.

Oliver Wendell Holmes Jr. is quoted as having said, “I would not give a fig for the simplicity this side of complexity, but I would give my life for the simplicity on the other side of complexity.”

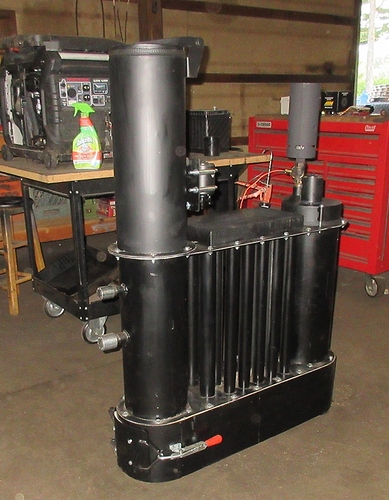

Well the day has finally come, the first 2019 FPS is ready for its journey to its owner in Montana. Only four months over due all due to that hopper agitator. Now to update and get to work on the remaining 2019 FPS builds. There are three more to build two are kits going abroad and the very next one is going to Kentucky.

Many updates to make to the CAD models and then CNC code files updates. The next ones should go fairly smoothly now that everything is ironed out. This machine will set the foundation for many years of production. Up to this point there was only one year where I carried over a design unchanged. Even then I think there will still some minor changes on that one.

The FPS marks the beginning of commercializing the first production gasifier system since WWII. Most current production machines are still labor intensive hand set up custom builds. This machine is designed and ready for mechanized automated production systems. I could be wrong, but I have not seen any commercial available machine to this point. Not even my major competitor. For instance Ive worked on a machine that makes tool chest for Waterloo. This machine can take a very large roll of steel sheet, and fully stamp it, bend it and make all the spot welds to fully create a lower tool chest and do this in 14 seconds. Ive retooled a tire mount for a GM production line that can fully mount a tire on a rim and fully inflate to an exact pressure and do this every 17 seconds!!. This is the type of automated machine tools that could eventually reproduce the Flex Power System. It is designed specifically for this type of processing.

Now to move on to the VersaFire. I should have the foundation for the little DC genny just about complete this week. This is just the engine and generator set up. Once I have the mechanical foundation complete I will then add the filtering system, enclosure, mixer valve, system blower and then start working on its automated controls systems.

Congratulations Matt

That is a good looking system what a relief it must be to finish a prototype

Now to get paid and have no startup teething issues

Congradulations on your latest product gasification generator fuel supply /ect electric./ heat. Liveing the dream building products too sell on line, i agree with mike gibb, neat new looking design, good luck with your products too design and sell.

The Utility Gasifier is Back!!

All new design featuring lots of things learned this year from the Flex Power System. It shares the identical reactor, the new fuel agitator, and a new revised light version of the Thrive OS. Later versions I plan to incorporate a fuller version of the software; making it capable of full automatic modes just as the Flex Power System. It will have a simple single button interface that will change colors displaying what mode it is in.

Should be wrapping this up soon. But I still then have the software to rewrite, should be easy enough, with exception to the new servo valve. The old version had 180* movement. This new version is direct couple so it is 1:1. So I have to figure out in software how to create limits. I think it will be straight forward, as I will tell the code to write a safe value for when its in the range and unsafe value when it goes beyond those limits. Hope that works love beating my head against the wall writing code

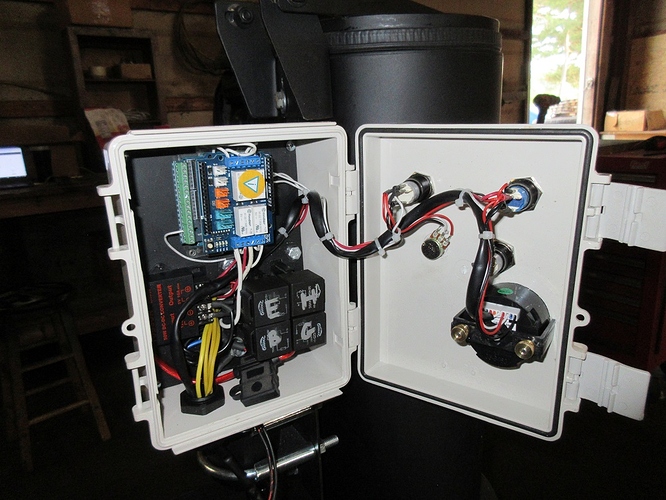

So I built the next gen controls. first one anyways. The next one may get arranged a little differently but for the most part this is how they will be. I managed to cram in the full gasifier management system, the mixer control unit and engine system on/off along with a starter button.

If I add in the wet filter and liquid cooled chiller option Ill have to but this in a larger box or integrate the controls directly onto the machine. That maybe a challenge as there is not a cool place to hide them on the machine. This would be more desirable if I can figure that out as it less cost not needing to buy a box and it looks a lot better.

But everything is here to make this controller as is fully autonomous.

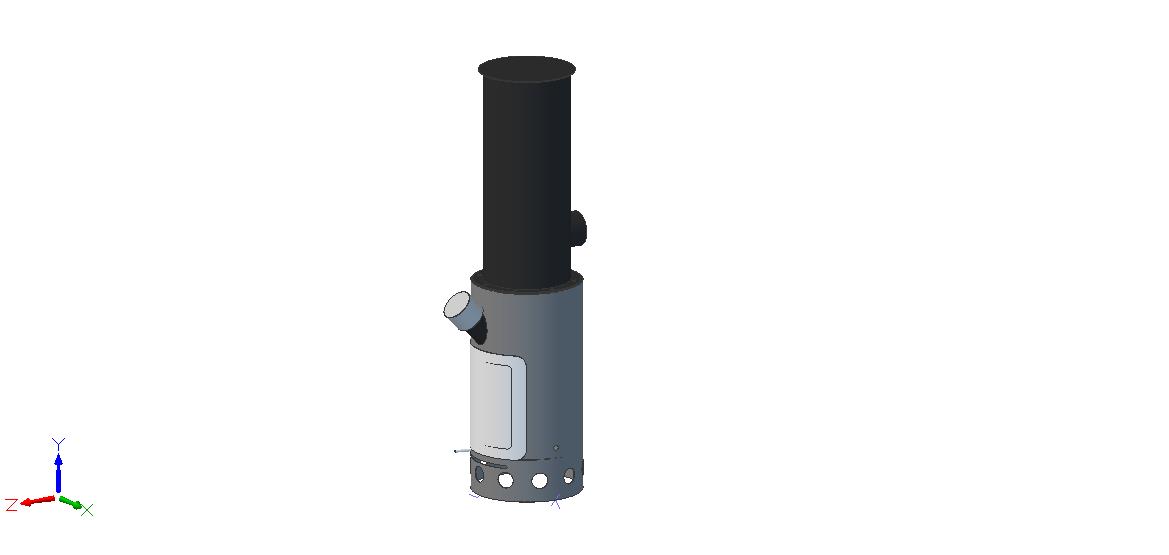

Ok well here is another CAD model. This is the Worx Gasifier!! This is based on the Utility foundation. But has the worx package of every possible thing I could take from the Flex Power System and cram it into batch run machine on wheels. It will have the full version of the Thrive OS along with a slightly revised version of the electrical systems. So this machine will have full automatic capability along with the touch screen interface.

In order to increase run time I added a massive 80 lb hopper to this thing. Should render a minimum 12.8 hour run time @ 2.5 kW full time load. Coupled to a battery bank and only running in charge cycles easy 24 hours of operation. Only thing is there is a cone involved  haha those big ones are not too bad to roll though. Its those small ones that suck.

haha those big ones are not too bad to roll though. Its those small ones that suck.

Well Ive spent all weekend on over hauling the website and added all the new products I have conceived for the 2020 model year This will be the largest product line Ive had since around 2014.

Other than the VersiFire this is pretty much it as far as the physical machine development goes. The designs meet the function and performance levels I had set out to accomplish 8 years ago. Another criteria was making them manufacturable and these machine designs are the first I would say meet that criteria. So Im going to lock those designs down. There maybe slight alterations, If we can find simpler ways to do things than its a no brainier to implement those things. But for the most part the designs are solid.

Im going to offer the updated 2020 Utility Gasifier for just $2500 bucks with 50% due at order. This is for the base gasifier only, no automation, no blower, no wire, no wheels no nothing!!! haha just the gasifier by itself. However I am going to offer everything to upgrade it at all levels; All the way to the Worx Model.

You can check the new products here if interested. The Enduro Stove will be available for $850.00 bucks. This is a gravity fed 40,000 btu extreme efficient stove. 20 lbs will do what 40 lbs does in other stoves. The way they rate stoves kills me, they dont fully calculate all the waste.

https://www.thriveoffgrid.net/store?origin=notification&postId=5d87dc4335544300170be5d2

Well we failed to make sales quota for 3rd quarter, so off to work I go. Going to change the companies direction. I have four builds left many are in progress, so I will finish those builds with a goal for completion by late November. At that point I will be working on reorganization in preparation for mass production and launch a production run second quarter of next year. I will soon address the website with new pricing and take deposit for pre orders for that production run. The good news is my pricing will go down on higher end models the bad is it will most likely go up on the lower end machines. However the pricing gap between models will become narrower. Mass production vs build to order are two very different things and the mass production level is where Ive been trying to get too. So that is where we are headed. I am currently working on projected cost analysis and should have new pricing soon. Right now I have it raised up temperately. This is just a guesstimate but I think the base Utility will be around $3k and the full blown Worx SE will be around $4500.00 and that machine will blow every machine on market away.

So I am tuning a base model Utility tonight, and tweaking the new controls. The new controls is pretty cool. It has an on/off button then a mode switch that shifts to different modes. First press turns on the blower motor so you can light it. Then second press puts into engine run mode with manual mixer adjustment. Then the third shifts it into auto mix mode. There is an engine starter button directly on this controller along with a coil ground. So you can fully operate any off the shelf generator remotely directly from this controller.

Unfortunately I am going to have to tune this machines hearth. I had set it up just like the Flex Power System earlier this year and I had to tune that machine. So it is looking like Ill have to do that same on this one. Ill get it done though, that will be a tomorrow project and then finish setting up the controls to my test genny and get a good video of it. Quick note this is a 2018 machine the design the new one is slightly revamped for enclosure and an boards controls.

I will be building my very own for the first time since this company existed and it will be mine and all mine and no one can have it. !! Ha!! That will be a Worx SE and will be the machine used for manufacturing development and pressure testing process. Once its done then it will be used to power our operations.

I really like the mobility of this unit.

Yeah me too, it makes it so nice to move it around. They are heavy machines dont let the small compact size fool you. I still have to weigh it, but I bet it is close to 250-300 lb range.

Yeah so its getting a bit nippy out there in the shop. If you know me, you’d know I hate the cold!! So all these years Ive ran those torpedo heaters and ever year I say Im done with those heaters and then end up buying one the following year. We did have two stacked barrel stoves in the 50 x 80 cinder block shop and those stoves gobbled up two cord a month!!

So this year I have an endless supply of waste oil. So ive done some research and am working on a new multi fuel stove. This is a cylinder style rocket stove that will be able to burn chuncked up wood, twigs, sticks and able run in a Kerosene mode. So if it can run in Kerosene mode then it should be able to run waste oil, veggy oil etc. I just cant market that way so Kero mode is the marketing. This stove will be convertible as well, so the top heat exchange tower could be removed to convert it to an open top outdoor cook stove.

So this is priority on my agenda so I can get some warmth in that shop and then can work more comfortably.

I am also bringing back the Micro gasifier this year. This will be an experimental unit and will take the place of the TOG kit I offered earlier this year and had as Argos.

`Stove is done, just need to build the 3 to 4 inch adapter and the fuel tank. Then I just have to plumb everything up and mount the fuel tank and its ready to heat!!

Will this be an oil drip method? Will you use hot coals to vaporize the waste oil? Waste oil is dirty, smokey stuff and not easy to burn clean.

Yes this I am learning. It is nasty!! Yes it is a simple oil drip system. I am thinking of how to get to burn cleaner. It does have a second stage air / burn chamber.

I wonder if I could install a catalytic converter in it.

It seems most I have seen have some sort of blower forced draft. I tried the oil drip on hot coals once. It was nasty.

Yup it is a smoke factory on oil. lol. However, running on blocked wood like a Kimberly this stove is quite clean. Im wishing now I would have paid more attention to that part so I could get more fuel in it. I might offer both versions because it nice with the port system for shoving in small pieces plus you can use this to poke it and stir it up.

Matt, cool stove.

I don’t have an oil drip in my stove(wish I did) I just take a metal can or old oil filter and fill it with oil and shove it in the fire every once in a while the oil bubbles out of the can and gets burned along with the wood.