Gee Matt I was real excised about that small gasifier for running a small engine on wood chips. You have done a great job with your design. What can I do to help?

haha you could come here and work lol

However as posted above I have caught up our production and that required 100% dedication without other projects to side track. Now we are moving and relocating to a new facility. Current lease is up and we need to move on. So the shop is temporarily shut down for the next four weeks or so. Once things are back online Ill see where things are at and how to proceed.

Cheers

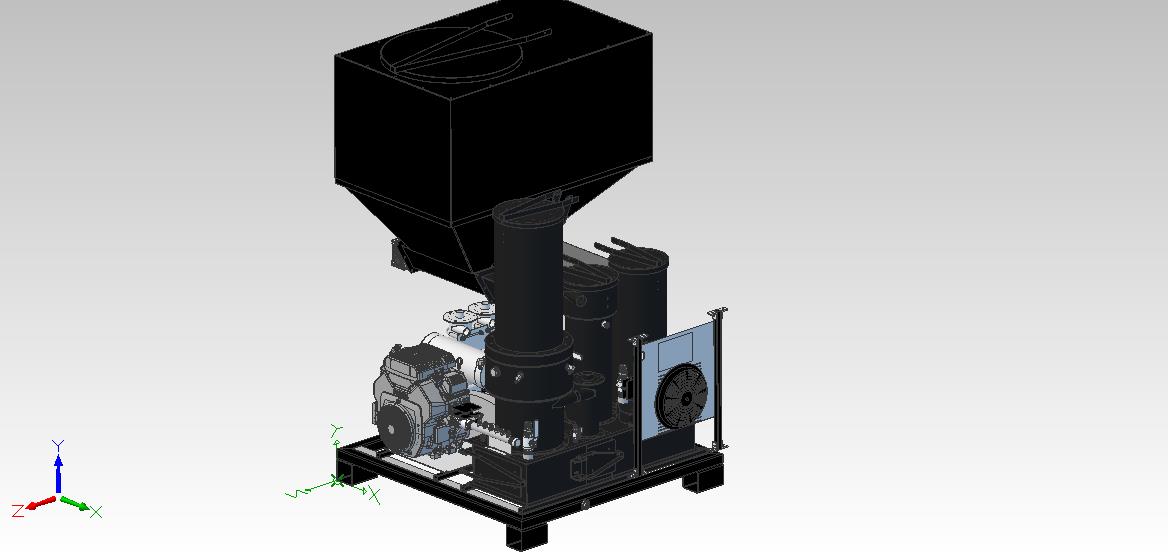

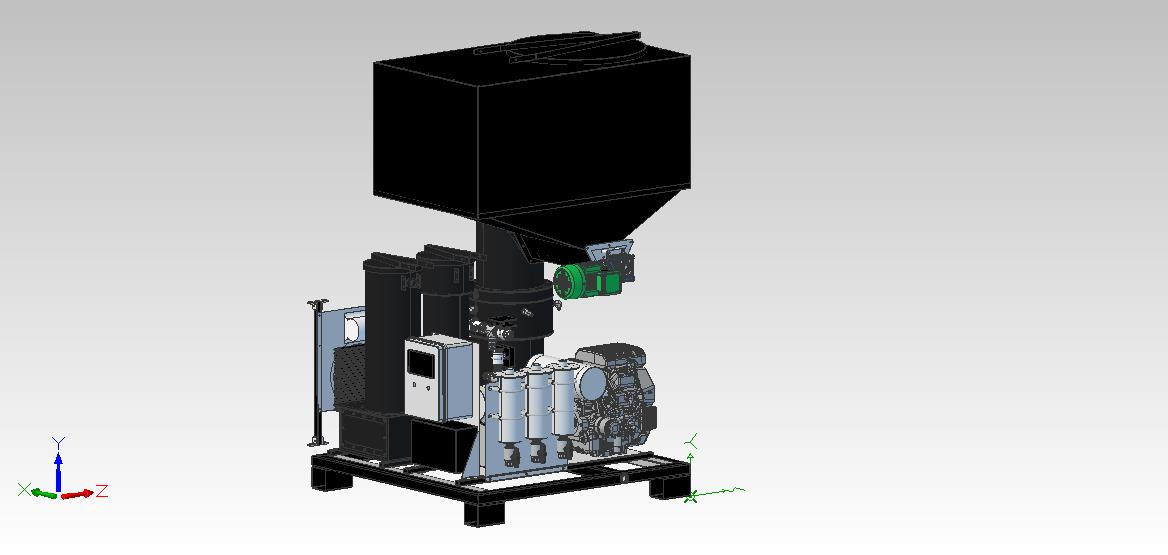

So Ive had some down time in our move process, but no rest for the wicked. So Ive been busy working on design work of the 2018 Evolution machine. This thing has the HGRS with the secondary after burn reactor, full auto system, (this thing will run itself including light up) twin onboard 48 volt batt bank with inverter tech, liquid cooled gas chiller and exhaust CHP heat exchanger. Im sure Im missing more lol. Note there is only three in the cyclone series bank, this is all I can fit so it is what it is. This will produce 8 kW generator power with up to 14 kW battery driven out of inverter in any phase up to 240 volt. I hope to work with Koen on a future project that we will rectify current into a PV type inverter that have much higher voltage outputs for larger applications. This will allow us to very easily team multiple machines together to create very large outputs. Lots of advantages to that, to many to list for my attention span

Hi max does the secondary burn reactor improve the emisions or inprove the power of the fuel,OR? PS. What might be the HGRS my memory is fadeing.

Hi Kevin, well this is very early development phase, so i only can offer theory at this point. I have done proof of concept on a crude set up on a smaller machine. This new reactor is designed to work in unison, with the HGRS system. This system is sort of like a charcoal unit that makes its owns charcoal on demand.The HGRS takes out the hopper gases and is used as a medium to carry engine heat back into the system. In the lower reactor this gas will control its core temperatures while performing steam reform processes. With the second reactor, we can then lower the amount of input air into the upper reactor as the HGRS will perform a good portion of the pyrolysis in the upper stage. This should reduce the amount of co2 in the gas composition while the combined system will hopefully boost H2 density in the gas… Then additionally there will be no waste, so that 15% of char yield will be put back into the system improving overall efficiencies while eliminating daily service of ash removal.

So in conclusion, we hope to see high combustible gas density (more powerful gas) substantial increase in fuel efficiency and ease of use.

Thanks for sharring on your new design plans, Good Luck wih the new changes.

Well Well, Im finally in the new facility!! So today was the first time Ive been able to do actual work since I moved out of the old facility last June. I am off grid and was running on gasoline for a while, since I had the TOG DIY machine half complete and in need of my own gasifier I whipped it up and did the final videos to complete it. I have it up and running now and it is powering the shop on pellets. I need to add some filtration and may need to jet tune it. I get some valve fluttering once in a while, I quick switch back to gas and run for 15 min and then back to woodgas. As long as it stays a RPM it does good, its when it gets loaded and bogged down I start running into that issue. I have this running the 8750 Predator with a single filter system, driving a 12 kW charge inverter. When the batteries get low and add more load is when it starts having some trouble. Other than that it been running pretty well.

So anyways Ill have video and pics of that coming soon. But next on my plate is the updating the Evolution Power System. Should have that ready to debug next week with the new controls.

So Im having some tar with my coffee this morning. This guy starts hard in the morning, and I think its due to shut down. To ease its construction and with making existing things work; I was not able to easily weld the outer shell of the hearth manifolds exterior fully. I think the combustion zone is voiding out due to this slight leaking and when start up there is too much raw fuel in places where it should be char. No biggy when I take it apart for rejetting ill run a solid weld around it to seal it.

This machine so far has ran pretty stable even with out automation it stay running. But power output is never linear, so I will be fully automating this. Keeping the grate clear and flowing is the biggest thing, the Predator pulls good and strong as long as I keep the grate clear. But I have to work to do and cant sit there babysitting it so Ill be automating that here soon.

Here is the video, yeah the move has been rough on me. Everything so dang heavy!!! So glad I dont have to lift any more stuff on and off a truck for a while.

Awesome Matt, thanks for sharing!

Matt, I can not say enough about being off the grid and depending on your products. What better sales tool and learning tool !

I know this will go down like a lead butterfly but here it is: one of the worst tools at work has been something called LEAN. But a few weeks ago someone recommended “2 Second LEAN”. I’m sold on it and have started to use it. Maybe it is hard to appreciate if you never experienced a sick version of it. Anyhow there is a free pdf version of the book with tons of videos. I know you feel that your operation is as lean as it gets but I want you to make a go of this and I’m willing to sound stupid in order to help ya out.

I think this link will work.

Oh absolutally there is a long long way to go here. Only just begun, Ill take a look always looking for ways to improve.

Cheers!!

Ok here is a lesson hard learned!! Ok well I did not think having slight leakage in the hearth intake manifold would be an issue, after all we have a big opening in it that feeds it air right?? Some slight leakage would surely still starve the machine for air at shut down?

Well ok yes it will still starve the gasifier for air and shut it down. The problem is something else, as the gasifier is shutting down it is still producing gas and that escapes through this leakage. In order for the gas to get here it must pass thru the jets first. As the machine cools down the gas becomes more more tar dense. This builds up in the jets and you end up with clogged jets eventually. So solid welded this guy and also opened up the jets a bit running now to see how she does.

So here is the completed TOG DIY gasifier.

If the very original M-1 were to evolve to today using the original construction techniques this is what it would look like

New jets came in the mail yesterday. I ordered two sets one set with 2" length and another set with 2 1/2" length. These are 1/8" NPT cut to length SS pipe… So I started out with 1 1/2" length giving the jet ring around a 5 1/2" diameter. I decided to go with the longer set even though I thought those might a bit extreme. With the 2 1/2" length jets this knocks the jet ring down to around 3 1/2" so looking down at it; it this ring looks very tiny.

So fired it up and ran checking the tar trap every few hours. There must have been a bit of residual in the system or it had to re establish it self or both. The first time I drained it dumped out 1/4 cup of black stuff. The consistency was much more fluid than before so at least there was a change. As I kept checking there was less and less being dropped and now today there is nothing, no tar or condensate.

Performance wise there is a slight decrease in power output and it is a bit more finicky. Air metering valve angle position is about the same as before. Much less smoke at start up and flare is completely transparent in daylight. At night its the typical peach color with blue base. The power decrease is probably closer to where it should be around 30% it was pulling pretty hard before there was probably only about a 20% loss compared to gasoline before the jet change.

So next step is I ordered a set of drums to create a new filter that should do a better job of filtering and cooling. So I should start to see at least some condensate drop at the dryer once that all installed.

Hi Matt, Have you ever had problems with the Predator generator not running? I was demonstrating running my 8,375 Kw genset last week on charcoal. Once there is a good flare, it takes one or two pulls for the engine to fire up. Well, this day it would not fire at all. Even tried ether. The plug was pulled and no spark. Clean as a whistle, but I hit it with a torch flame anyway and then it sparked. Put it back in the engine and still would not fire on chargas and only a few times on ether. The plug was replaced the next day with a Champion. Just for fun, I grounded it and no spark!?!?!? On a whim I put in in the engine anyway, gave it a shot of ether and away it went. From then on, no problem firing on chargas. My lesson learned is don’t trust the spark plug.

Gary in PA

Thats the first thing I change out is the plugs if they have the “torch” brand. I think they are an off brand of NGK but never the less they dont seem to be very good plugs. Had the same issues as you and changed them out with NGK’s. Those woke the generator up as well seemed to pull a bit harder.

However, the generator I just bought has Bosch plugs in it. So maybe they have had other issues and changed to the Bosch?

Clone spark plugs are like rolling the dice, well know issue. I’ve had problems with the low oil shut down circuit and carbs that do not work with gasoline but that is a good thing.

Geez, I just ran into this today running my neighbors wood splitter. Had to run to town and get a new spark plug when I seen it was a Torch plug. The splitter runs good now.

Well the machine started producing more tar again. So tore off the hearth and drilled it out to except 1/4" jets, didnt even think to look at the 1/8" jets until later. So went through all that put it back together and holy tar maker!! Couldnt keep it running so shut her down and went back to gas and after that the intake was so gummed up it dropped the push rod. Thought I blew here up!! Took off the valve cover worked the intake valve a little bit and put back together and all is good.

So I now go and take a look at those 1/8" jets and three of five are completely clogged up, forth one partially and only one clear. The only thing I can think off that Im doing different than on the manufactured machines is Im using an injector and to keep from blowing up my air compressor once I get it lit I switch it a presure mode. I can only speculate that maybe the air is flowing into that first jet that is inline with the inlet and the others are just static? I dont know and now I maybe adding inspection ports to the jets on the production machines so they can be cleaned out, this is probably going to happen and would not be hard to do.

So going back to 1/8" just need reducing bushings and back the original plan.

Thanks Steve, I think thats exactly whats going on.