Pretty nice there Matt ! What is the recommended fuel? Size? Material? Is that a four inch chimney? BTU output?

It should produce around 50,000 btu based on roughly 10 lbs of fuel that it can hold. I think it holds a bit more than that though.

You can run just about anything in it, smaller sized firewood, foliage, etc. Ive been running cut up skids from out back in it. The opening is 6" tall and about 12" wide. So if it will fit shouve it in there

Here is the latest video, I have it set up in the shop. I boiled some water took about 10 min to full boil. The cook top is the real feature on this, it will be cool to have next year camping just set up outside.

Just wondering how hot the heater runs before air shut down too reduce warping, looks a little small in the vidio for home heating.or is this a cabin unit/ That will help with your heating cost,you could allso heat a smaller area in winter mounth,if posibble,That building looks big enough too set up a portable work shop for winter, Thanks i would like too get some ideas on gasifier wood stoves,my buddys wood stove has fan between fire and duckwork,then the flame hits a big cement like block that turns red before it exits out heat exchanger.feel free too move this too new thread if needed/THANKS/

This is a portable pack stove. Its a stepping stone for us to develop bigger and better things. This is good for tents, small cabins, camping and things of that nature. I just have this setup in the shop for testing and development, and learning lots of things from it. Yeah the shop is 50 X 80 a little much for this little guy to heat, it cost $1600.00 a month in NG to heat this place. Cant do it on my salary, haha!!

It lights up very fast, about 5 mins and its time to shut down the flows. I have warped the top pretty good, we are going to add in 1" square tubing to help reduce this. The concept I was after works, it burns very consistent and through, and the heat transfer is very good. Chimney needs to be kept short, to reduce pull and reduce the gas cooling towards the top. You want your gas hot leaving out the top of the chimney or soots will condense and work their way back down and build up. Considering the what this is intended for this really is not an issue as this unit should be cleaned when taken back down; Again its not intended for daily use, we are working on that now. In fact Im working on it at this very min. November will be here in a month and I need my shop stove!!!

Thanks matt,sorry about my poor reading,i failed reading class more than once.Good luck on your other design for home heating,if you like i will get the name brand of the one i was describing,I should anyway too get a manual if possible for a better description.

No thats not how I work, I must learn everything the hard way!!!. lol

As a bizz I do my best to avoid all outside influences this is very important to us to keep our design work ours

No problem, I suppose it could be a legal effect otherwise,I have best luck learning by finding good working designs,and then perfecting from there, and i dont know any sort of buisness planning, Any way i can build a higher efficency heater i dont care how i get there,long as it saves wood,and keeps warm,saves me time and money, Sound good,makes sence, good luck,Thanks

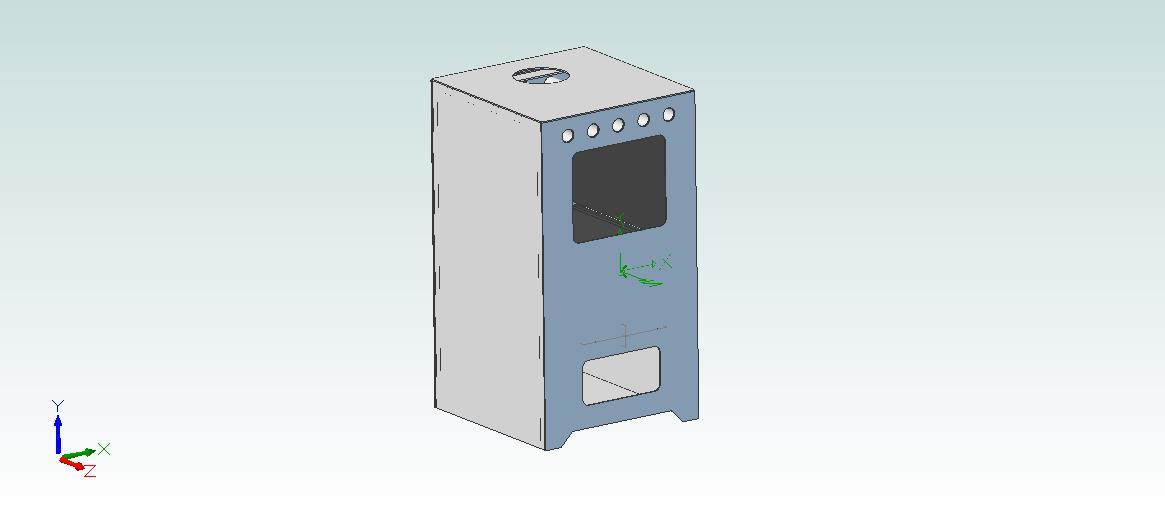

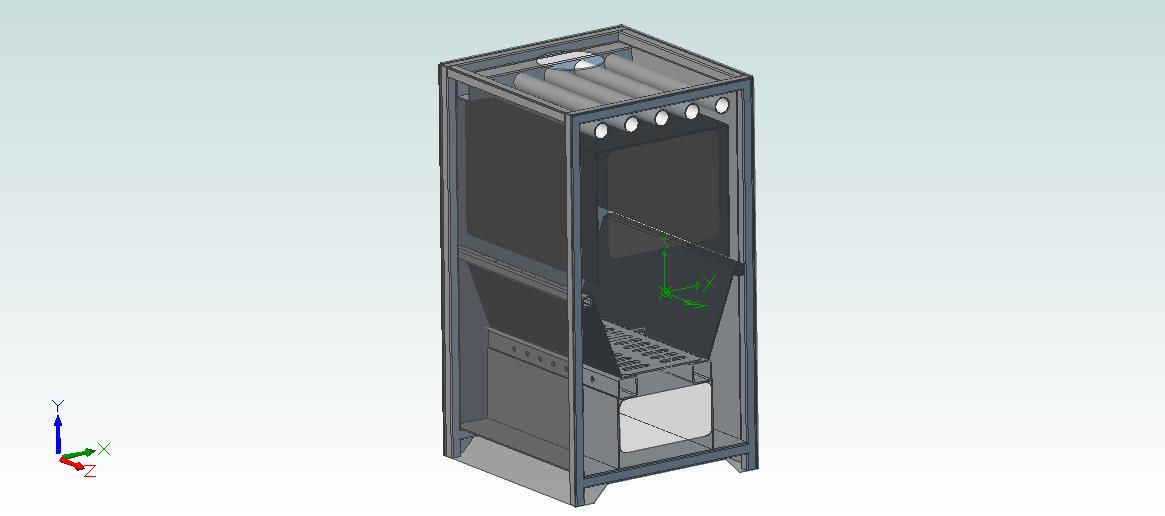

Well this is far from done, but this is where Im at with it. This is a naturally aspirated updraft with secondary air leaving the hearth chamber. There is a 1" wall gap from the exterior panels for heat transfer and to create a natural flow up to the manifold heat exchange at the top. The top panel will be bolted on, not welded for servicing, prolly gonna have lots of bolts there.

This again is a very small unit, only 36" tall x 20 x 20. If it works as hoped we will offer it as is and later with forced air as the later is the goal for the shop heater.

HI matt is this a gasifier, water boiler,or regular air heat exchanger on the top baffle area

This is just an air heat exchanger indoors system. Not sure I want to the go the route of the boilers. Maybe later on.

That looks like a good design,with the magic heater type tubes on top, for heat recovery,before it gets out the chimney,with the longer chimney,you might be better with dry seasoned wood,even without extra recirculate gasifier system.The only good part of the water is the distance from the home can be farther and move the heat easyer,than with hot air.the old style wood boilers burn up more wood and are about outlawed too build in some states,the new style boilers are built too burn dry seasoned wood only.The stove i was checking out runs about 1000 degrees hoter than some of the older water boilers.around 2500 f at the catalytic block on bottom of unit,before moveing out to and past the pipe heat exchanger,I just dont know how the fan gas system travels yet too aid in the gafification.I know the different designs are out there, i havent had time too study them yet, One of each type would be wise if the gas line gets too shuts down. LATTER

Outstanding video Matt! I like the center barrel dropbox/cyclone/cooler setup. How hot does that get? Do you find most of the stuff that settles out is at the outside perimeter of the barrel where the cyclone effect throws it so it doesn’t get sucked up again by the center drop pipe? How large (2 cylinder) engine will that handle?

Hi Don,

I had many doubts about this machine. How much it would run, stability and that cooler / cyclone thing. The cooler was very surprising it works!! Yes we took off the top and sides are coated nice and evenly and you can see the swirl pattern. It does get quite hot and it is more of a precooler before getting over to the fine filter. This is fine I think, the gas is plenty cool by the time it leaves the cooler and the added moisture in the hay filter aids the filtering process. For what it is Im quite happy with it. We did a lot of stupid simply things that work, that the high end machine may inherit.

I think 15 hp is going to be the maximum this will run for practical and stability reasons. The engine in the video is a 9.5 hp Kohler and it runs that very stable, so this is the range Im going to recommend.

Well finally got things caught up and ready for the 2016 model year. I got our shop all cleaned up and reorganized and set up for the new production systems. CNC is mostly done so we are cutting full sheets at a time now on all products. This is so much faster than one piece at a time like we have done before. Thats a lot of work without the software, this is like a giant jig saw puzzle trying to fit all the parts onto a sheet with minimal scrap.

So anyways back to building the Flex R-1 builds, they are coming along so nicely and look cool. The new ash clean out turned out really nice and is just going to be nice feature. No more breathing all that dust during ash clean out

Really nice and clean looking unit Matt!!!

Yup… what Herb said, nice looking machine

Yup little by little.

And to think this is the very first Micro and all developed from here.

Good evening Matt R, Those 5 too 15 horse machines should sell pretty good it seem like, Are the tubes easy too clean out from soot build up, Looking good