We can build one for you

I uploaded it to my Google Drive (111kb) and should be downloadable from here: https://goo.gl/MDsdGf Of course any words are in Polish and any measurements are Metric, but it should get you on your way at least.

Looks like a lot of whittling on those shafts. I think it could be done simpler, those shafts would be very expensive to create.

That was my thoughts and I’m not even a machinist.

Yup, Im thinking…

I think we could replicate the shaft in a weldment. We can purchase the shaft already keyed and weld a webbing to it with mounting plates. Ill have to tinker on the CAD and see if I could come up with a design. What I have in mind I think we could build the entire thing with engine for around $1500.00 or may be able to offer parts to create the mechanical rotating mechanism and guarding for a couple hundred or so.

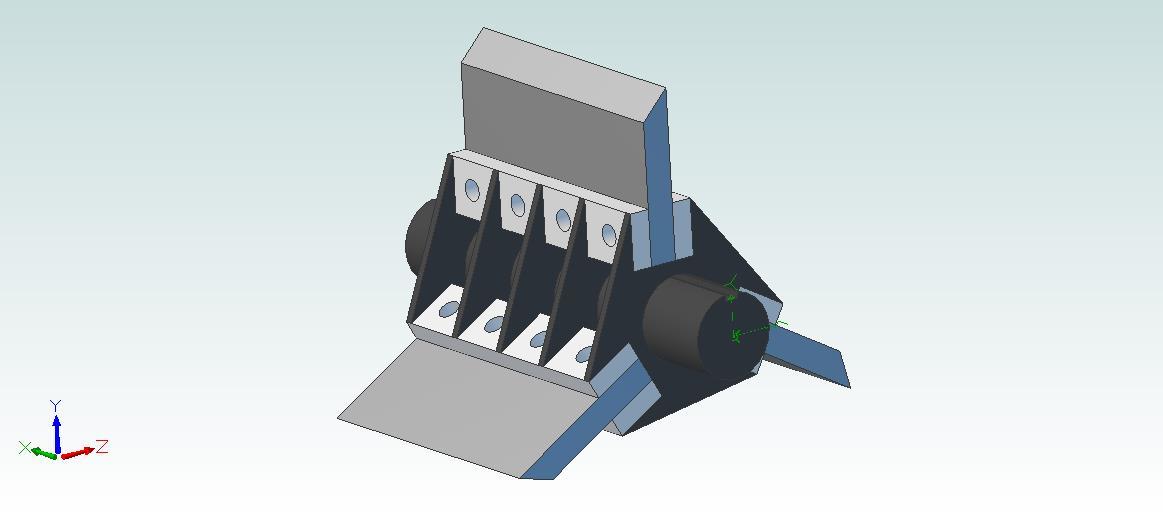

So here is what the rotor assembly would look like with a webbing and mounting plates for the blade. You would preassemble this before welding. I dont think it would really need any balancing as this will be a rather slow rpm machine. The rest of it I think would be pretty easy to build.

What type of material will you be using for the blades?

I would use tool steel and heat treat it

Hey Matt, I would think that the blades would have to be adjustable, to keep them with in specs. after sharpening. Al

Hi Al

In Europe this machine is normally sold with a set of shims to shim the blade after sharpening to get as close as possible to a zero clearance between the blades.

Hi Mat

A square rotor chops shorter chunks than a triangular setup

Regards

Werner

There is a lot of force when those two blades are pushing that log through!

Hello to Everyone

I bought these plans from Zygmunt in Poland. My unit is almost complete.

http://olx.pl/oferta/rebak-rembak-walcowy-CID757-ID8Bw0x.html

Regards

Werner

I think that is importatant for gasifier chunks.

When scaling up, chunk length will also increase rapidly. I think it´s best to stay with no more than 5" dia gears. That will make it handle 2"- 2,5" dia wood.

I went redneck route and bolted cutting blades to square pipe rotors. I´ve chunked a couple of cords so far and no issues except for my, not to recomend, chain drive.

I was think going that route as well.

New project coming on the market. We are calling it the BioWind Systems.

LOL Chris, I knew this was going to happen. hahahaha!

I’ve been wondering who makes a good inverter, I see your using an Aim’s. They must be one of the better choices.

Nice system ya got there…!

AIM’s is middle of the road, they make high and low end inverters. Their high end products seem to be pretty good, we have had good luck so far. However there are better inverters available, you get what you pay for sometimes. We are going to try this inverter as it has some very good features and is one of their more prideful products. Im excited about this system I can not wait to build the first one. Missouri Wind and Solar have been a great help in putting this all together.