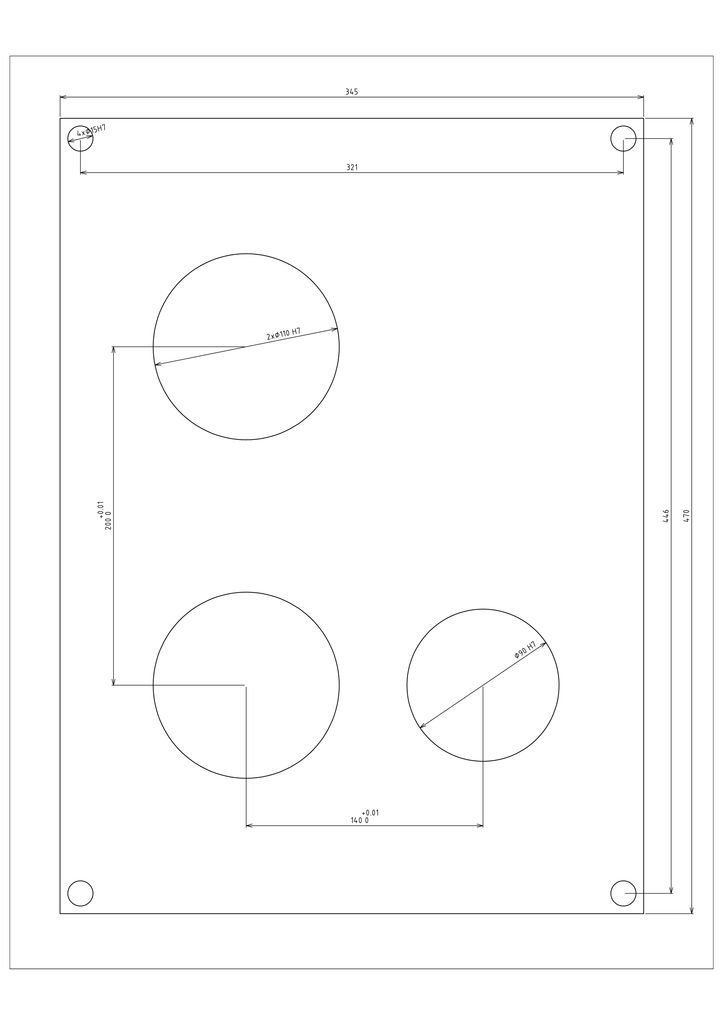

Arvid if you are serious, here are some drawings I have of one. Don’t know how many will post but I have a total of 6

Arvid Click on each drawing and it will expand. Then click on the expansion for that and you can read the dimensions very clear. I think the spacing of the two big gears determine the length of the chunks that come out. That spacing has to be considered in the size drums and knife lengthTomC

Thanks for the drawing Tom.

So as I see it, the distance of the arc between two blades determine the length of the chunks and the distance that the blade extends past the drum (times 2) determines the thickness of the stock that can be run through.

My hesitation lies in the species of wood the Europeans are running through these machines. My guess by the looks of it, it may be reasonably soft wood? I’m wondering if it will stand up to some real hardwoods?

Here’s another version with the drums further apart with longer blades.

Thank you Tom… I’ll do some studying

Good morning Bill and Jan-Ola,

Thanks for posting the videos . I like those wood chunkers !!

Bill thanks for the posting of the chain drive— always thought hobbling out special gears would make this a killer for us “play” boys.

This is a single blade Slecovac (?) Might be easier to build.

Sorry JO Some how I missed you video on the swing blade that you did for me. I saw it now and appreciate the video. Very nice. I see a lot more work went into the swing blade build than I thought when I saw the wooden frame and cross pieces. I have in mind now what might be a much simplified build but I don’t want to cut “lumber”, just small pieces that I can chunk for my gasifier. Thank you TomC

I’ve never seen a sawmill setup like this before. especially the tractor mounted deal. Seems a wee bit dangerous.

Good morning Andrew .

New saw mill to me . Never seen one just like that.

" Seems a wee bit dangerous." I have been taught never to stand in the sling path of the spinning blades , If a small fragment or saw tooth was to turn loose it would be like being shot at with a 22 caliber rifle .

A bit dangerous but those Aussies are problem solvers. I would not want to be behind that blade at the mill.

I wouldn’t say a bit dangers’, I would call that a accident waiting to happen.

I have ben around saw mills and logging all my life, had friends and neighbors killed or injured in timber work. I have a lot of scares and a few broke bones myself.

ps---- search ten most dangers jobs.

BillS: I wouldn’t quite say problem solvers more like very lucky lunatics!

Seeing the guys reaching an inch from a 6 foot diameter milling blade in use was quite cringe-worthy.

I noticed that their Mobile Milling Blade the huge circular saw blade on a backhoe arm thing was spinning backwards compared to almost every other saw blade I’ve seen used. I guess it it technically the “correct way” considering the wood is underneath and the saw is effectively “upside-down”. I still couldn’t help but visualize the blade breaking free to “drive” itself right into the cab of the tractor. I’m guessing a blade that big moving that fast wouldn’t slow down a whole lot hitting a tractor cab.

I labeled them problem solvers because of how they loaded them big logs up on that truck. One has to admit, that was pretty good.

Hello Bill

Loaded logs like that a long time ago, but we used mules. I was in about 8th grade when I started working skidding logs with a mule. On loading logs I would be the one to move the mule back and forward to pull the logs up.

A very warm March so far. Getting into firewood drying season fast. Haven´t had time cutting and splitting yet, but I´ve been milling some boards/stickers.

After Tom Collins saw my mill he doesn´t want one anymore. Here is one more short clip anyway. My crap mill filmed wih my crap phone

JO

Hey JO; I am still interested in your swing blade saw mill. I have been on holiday so have been out of touch. I found a place that will build me a blade any size or shape that I want. I have a motor out in my silo that was used to unload the silo. Haven’t ever tried to run it and don’t know what HP is is but think it must be about 5 hp. I have so many irons in the fire that the lord only knows if I would ever get time to build one. In the mean time, I am able to get “stickers” from a local saw mill for my wood gas truck. I appreciate the videos.TomC

Tom, I know the “irons in the fire” feeling to well. I haven´t had time to play with my gasifier build in several weeks. Next is 25 m3 firewood laying in my backyard waiting to be cut and split. Work is stealing most of ones time. I mean that place where you spend your time when you should be home getting something done.

I always thought there would be more time left when kids moved out. Didn´t happen either. Now they want help with their homes as well.

Did you just say you´ve been on holiday?

JO

PS I was just joking about your opinion of my mill