Thanks JO, yeah, the video is coming, i just wish there would be some nice weather soon, just cold or wet or windy or snow, and “greyish” no sun…i like all seasons but can’t stand waiting for spring… and yeah, i know there are month’s before spring arrives…

Anyway, good thing i got promise to harvest some wood not far from where i live, thin stuff, around field edges, also something to look forward to. Then i gonna make some videos of my “wood processors”.

And other news: i haven’t let go of my thoughts about a tractor on wood, so i’ve decided to convert my fergie, which includes raise the compression ratio and rebuild a Ford-Bolinders gasifier i happen to have, going to start a new “tractor-thread” when i manage to haul the gasifier in my shop… ![]()

![]()

![]()

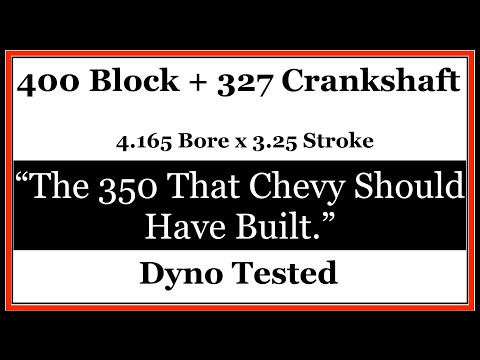

As if you don’t already have enough projects, here’s one to contemplate if you’re ever in the need to replace the crank in your 400sbc!

Thanks for the link Cody, that is interesting, i’ve heard a lot about 400 crank in 350 block, but never this.

I know i have to rebuild my 400 in the future, needs new lifters, and every gasket and seal there is leaks, have to pressure wash the engine day before inspection.

And, ofcourse, i’ve planned to mill down the heads some, these have pretty low cr. Also i need to plug the exhaust channel, heating spot in the intake, better to keep woodgas cool.

So… no more playing with chainsaws or old engines for a while, i really need to get this truck ready.

As the woodgas system is pretty finished, im going to concentrate on some repairs to get it ready for inspection (annual inspection) i prefer to do this on gasoline, easier for me and the inspector. I moved the truck on gasoline last weekend, and it ran like crap, smoking, missing, popping both in carb and exhaust, and ofcourse stopping. It haven’t ran on gasoline for a while so i decided to clean the carb.

Doesn’t look to bad, but there was water in the bowl, lot of it…

Cleaned out, even managed to save the gasket, carb gaskets are pretty tricky to make at home, and a carb gasket for an American truck are atleast one week away in Sweden, if you don’t have to order it from a younger salesperson… eeeh, what d’ you mean that “carbretter” is… eeh?

Checking the float and needle valve, and cleaned the strainer.

Earlier in this thread i wrote about i took the time to fix my fuel shut-off valve, with a push-pull cable, it was between that or mount an electric pump for easy shut-off. I went the cable shut-off route, and ofcourse my standard fuel-pump broke down… ![]()

So, now i have to mount the electric pump anyway.

Time to crawl under the truck, even if it had been nice i couldnt justify firing it up on wood just to move it backwards 90 inches ![]()

Ofcourse i parked the truck exactly on the extensioncord i need…

Well now its time for me to crawl under the truck and curse some… repairs needed from now is: new exhaust pipes, checking headlight “dipping”, drive it some for the brakes to clean up, oilchange, checking wheel alignment (maybe), and so on?

Make sure your ball joints aren’t messed up at the boots! Grease em up.

I think ball joints are one of the most forgotten maintenance parts.

Yes Cody, they are often forgotten, good thing Swedish car inspection (yearly, older cars every other year) are really fussy about all in wheel suspension, nothing escapes their tests.

On my chevy i pump in some grease about twice a year, a real money saver with grease fittings on the ball joints ![]()

U joints, ball joints, tie rod ends, sway bar end links if it dont have a grease zirk i aint buyin. Not worth the work to install it without one in my opinion

???never tried this.NEVER Replace Another BALL JOINT Again!!!!! This is a Seriously AWESOME Prevention HACK! - YouTube

Thanks a bunch Mr. Al ![]()

As speaking of sparkplug wires, these followed me home today, my brother used them, only a year, the angled connectors didn’t work with his headers, one cap burned, so he gave me these, now i can atleast replace the baddest wires on my truck (spliced and taped ![]() )

)

MSD used to be pretty good stuff, anyway it spices up my engine compartment some with colorful wires

Not really any “serious” work on the Chevrolet, but finally got those aluminum sheets in place, there was some side-bar tubes on the chevy when i got it, not really any benefits as i see it, but i let them stay in place.

But they irritated me, looking ugly in some grey, sticky epoxi primer, with rust “flowers” everywhere, hard to repaint them to look better.

Also clumsy as i am, i often managed to get my feet stuck between the bar and the kick-panels, which is a high risk for falling on my face, or hurting my ancle.

A metal working friend suggested this, he bent two pieces of aluminum floor and gave me.

Well, nothing wrong with little “customizing”?

Observe the evening sun picture, i didn’t notice my elongated shadow at first.

Ok, now it’s serious, on Wednesday i got a time for inspection for the Chevy, nice to get it road legal again.

Did some small work today, pressure washed the engine, (better to do before inspection, instead of getting disallow) changing some lightbulbs… but, no headlights? Ok, it has been parked long time, started searching oxidized contacts, and the famous culprit: the foot maneuver high/low beam switch, everything ok, what provides the headlight switch with it’s electrons? A fusible link hidden somwhere it’s impossible to reach it?

I can’t really understand what kind of problem the editor of my shop manual had? Those schematics are horrible, the light switch was hard to find, it was to be found at same page as glow-plugs, seems logic.

Anyways i managed to coax and pry the switch out from it’s hideout, and there it was: burned!

This probably happened when i still had the truck in traffic, i remember a occasion when the smell of electrical fire filled the cabin, after that i think i had more “friends” down the road, people flashing their headlights at me (to remind me: lit headlights are mandatory in Sweden, even daytime).

Found a old, unused switch in my stuff, which probably would work, only problem is it shuts taillights off when headlights come on, but i can solve that with a relay.

That is a NOTORIOUS square body chevy problem! I have replaced MANY of them

I can believe that, in this case the previous owner had played “the little electrician” and wired high beam to all four lights, and also low beam in upper lights at high beam (h4 halogen bulbs in all four), to get better lighting, not good for the switch…

There was also connected 2 light switch saver relay kit’s, but these was powered through the standard switch which made them totally useless… ![]()

![]()

While you are in this deep make sure the lights to the trailer hitch connector work. If I recall correctly, and I may not, those are pigtailed off a connector in the rear, and can get corrosion in them, then causes weird light issues. Similar to the weird things that happen with a corroded ground connection.

Yes, that is often a place for trouble, i had to re-do it when i got the truck, i put in a water-proof junction box under the bed, for splicing out the wires for the trailer connector.

Rainy today, i drove the truck to my workplace to borrow a hoist.

Got some things fixed, the exhaust leak, i did a quick-fix front wheel alignment, checked brakes.

This small leak caused all that noise? Well i could get my finger in on the upper side.

I also replaced the light switch, then testing, …drumroll…pull the knob…Nothing happened…

Well, now i had volts down to the foot-switch, and back, both high, and low beam, and juice at the junction under the hood, why no lights? Checked ground points, connectors at the bulbs, and everything.

Then it hit me: on the right side inner fender i had put four heavy-duty relays, supplied directly from the battery, to relieve the switches, and get the volts up at the lights, on some occasion i managed to pull some connectors at the relays.

Easy fixed, i had totally forgot i had put in those relays ![]() well, the main light switch was toasted also, two electrical faults in the same “system” tests your patience.

well, the main light switch was toasted also, two electrical faults in the same “system” tests your patience.

After work today, Chevy is up in the air again.

Welded some rusty mounting points for the bed, and slab’ed on some new undercoating.

Replaced the front brake pads. Pump’ed some grease in the ball joints.

And a oil change, notice the truck are a little to wide for our four-pillar lift, thrilling to drive it up on the lift with nobody there to help me point.

It didn’t fall off the lift so you are good this time. A little TLC Tender Loving Care on your truck. It will be Driving On Wood soon again. Have you bought any lemons yet to help with the SWEM you will have on your face Goran?

Yes, it went well, now the TLC are done, im the type of guy that saves all reparations to one occasion, not fun at all, better doing stuff along the way.

Today is inspection day, so we will wait and see if i need to buy a bag of lemon’s on the way home ![]()