Koen ECU and OBD2 modify the feedrate to fit the load?

Yes Thierry, and adjust ignition, reduce injection and so on…

why then, on the wood gasifier, install a cable to turn the ignition distributor (as on the pickup of Chris or Wayne?)

most probably they are not obd2

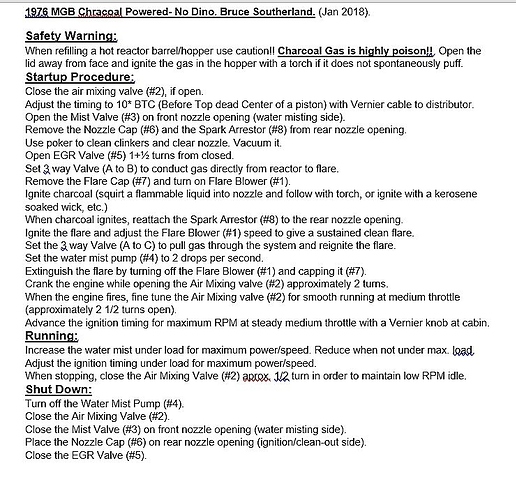

Hi Bruce:

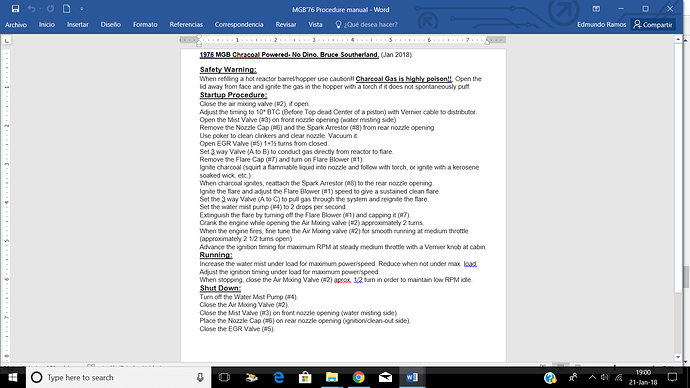

Thank’s for the sugested procedures!!

I have some issues:

- It is Ok the two ammo boxes drain I added?

- I assumed that when you say “Air mixing valve” is what I use to say “Adjustable from cabin valve” so I rename it accordingly.

- Can you sketch or take a picture or a video of the Nozzle air inlet Spark arrestor fitting and the cap.

- It will be just great if you can suggest some trouble shooting advices.

- Please find attach and check the next three files.

Thank’s a lot.

Truly Yours.

Eddy Ramos (Argentina).

Hi Koen Van Looken:

Are open to share your truck gasifier desing?

I will be more than happy to draw a sketch of it!

Eddy Ramos

Truly Yours.

Hi Ramos

It is a colossal work and a great generosity for all our wood - gas community, thank you very much.

Thierry

Eddy,

- Yes, I actually do have those drains on my ammo boxes.

- Yes, agreed.

- I can’t think of anything, except use a check list to make sure you haven’t forgotten something.

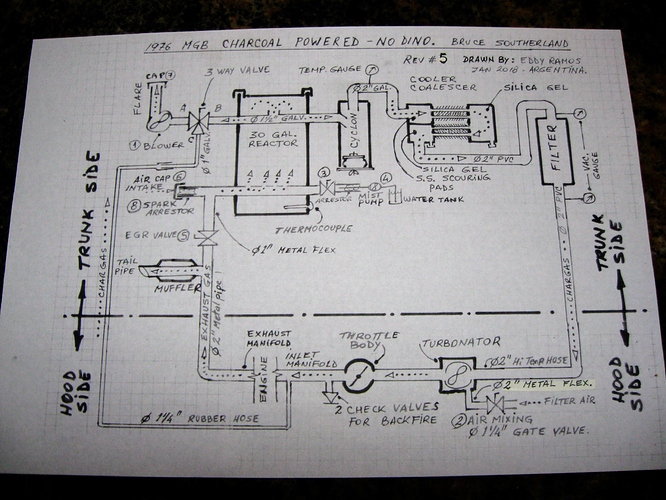

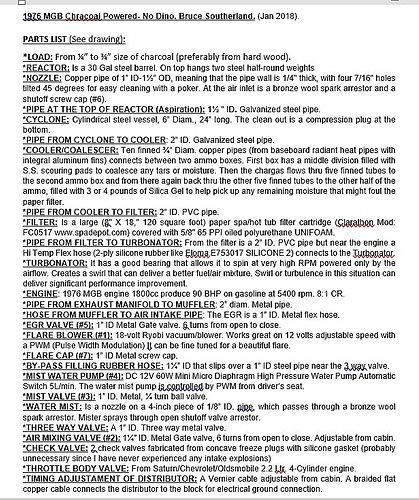

5.Looks good, except hose between Air mixing valve and Turbonator is 2" flexible (not 1 1/4 and not high temp).

Thank you for helping us capture this info for future reference.

Hi Bruce.

Thank’s again for your sharing with all the world your promising design.

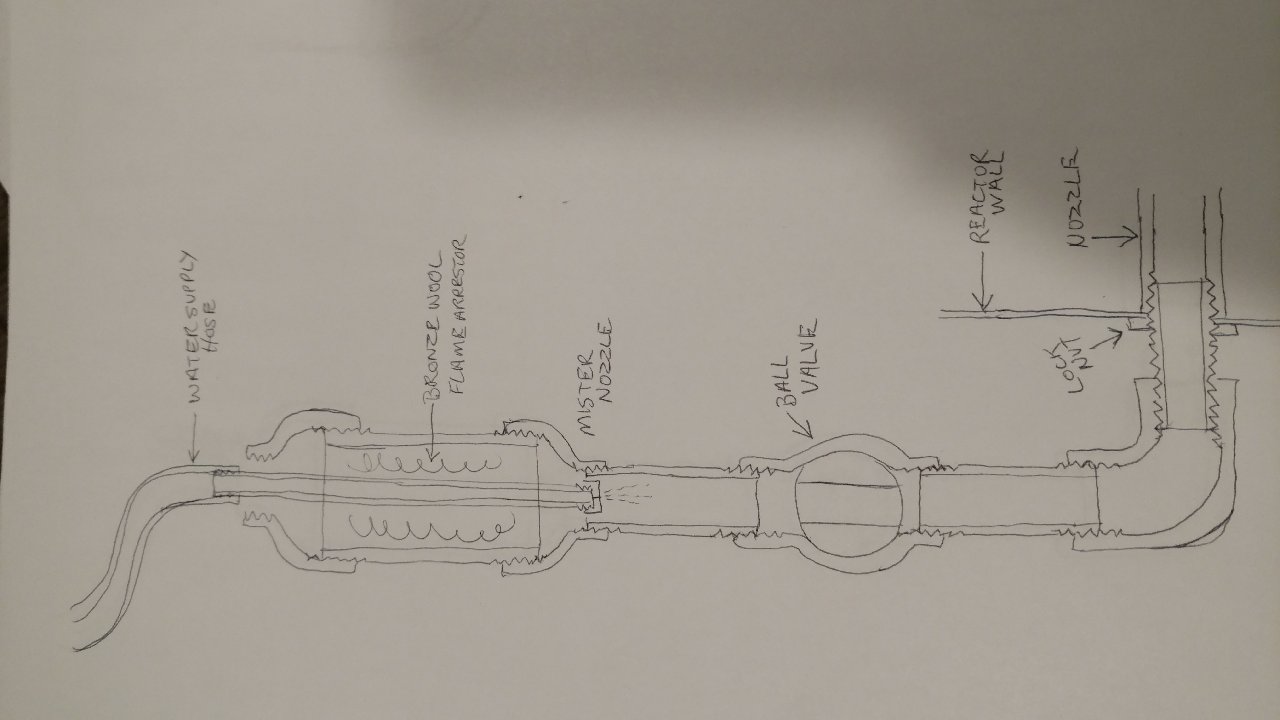

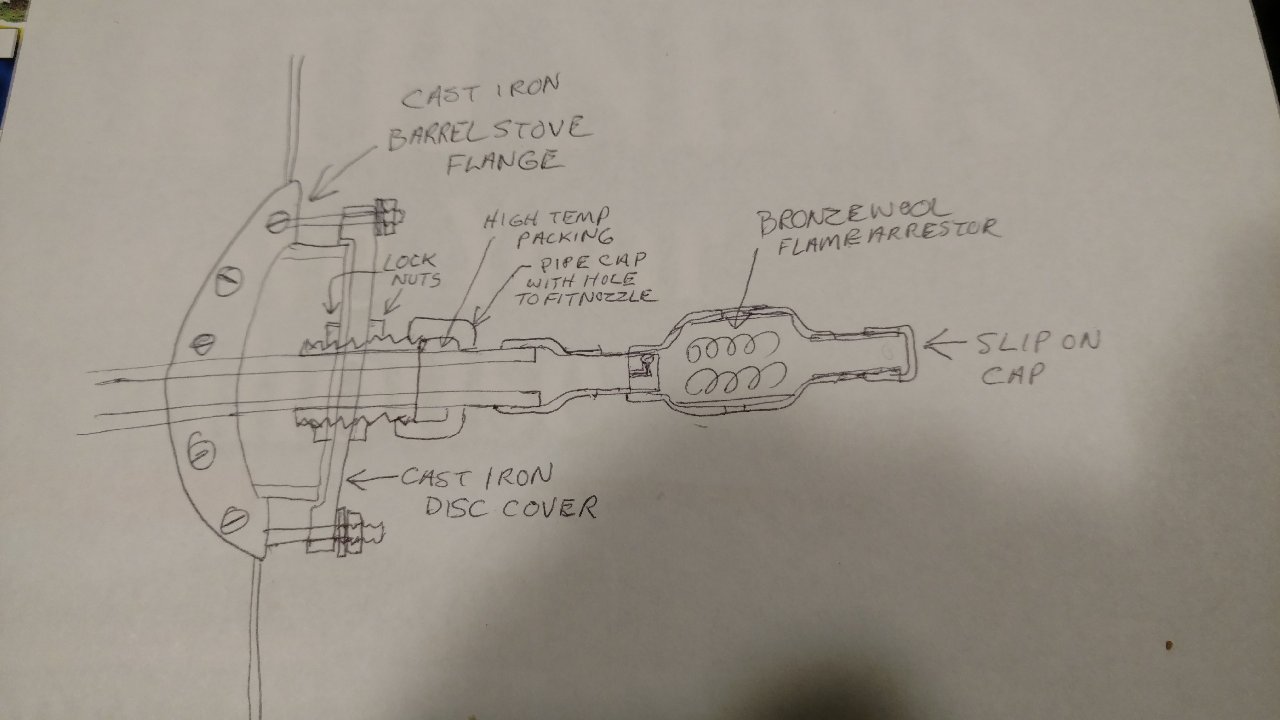

Thank’s for the picture but I can hardly understand how everthing holds in place and you avoid losing the arrestor and the cap during the riding. These two fittings (Cap and Arrestor) are all screwed one over the other and over the inlet air pipe??

Please check the Rev#5 drawing.

Hi Thierry.

Thank’s for understanding the extension of this work.

B.R.

Eddy Ramos (Argentina)

The cap slips on and is only used when the car is shut down. The spark arrestor has an L-shaped slot that slips past a screw that serves as a locking pin. The arrestor twists to lock in place, yet is easily removed for cleaning and lighting.

Hi Bruce:

Thank’s again.

I am probably too ambitious…sorry for that. I was hopping to make a detalied sketch of how the nozzle holds in place in the reactor and how it connects with the front pipe (air side) and the back pipe (water mist side). Do you mind making a very basic sketch of it? Then I can go from there.

Truly yours.

Eddy Ramos.

I will try to get to this drawing assignment soon. BTW, the filtered air mixture flex hose is plastic duct hose.

Hi Bruce;

NICE JOB!!!

I do not need to redraw you drawing. It is very clear to understand.

Thank you very much.

Truly Yours.

Eddy Ramos ( Argentina).

Hi Bruce

do you think a fuel pump ( engine injection) could it pump water?

I recovered one of these pumps and I think to use it to inject water in my gasifier (with an injector)

Its worth a try. It would be easier to regulate than drip method.

I don’t know about the injector fuel pump. The amount of fluid being pumped seems about right. See post #54 above in this topic. I use that kind of pump with a misting nozzle and a PWM for controlling the water flow.

I don’t know if this is directly applicable, but it rang a bell…