Good choice. A very sturdy blower that moves a lot of air for its size and price. I use it every day pulling sooty gas straight from the cooler pipes on my wood gasifier.

Hi Tom, Glad you finally got a flare. As you note, those small air leaks are a real bugger when it comes to charcoal gasification. Regarding your “survival gasifier”, I will say you are making it much more complicated than necessary. Who is going to find a pressure cooker in a survival situation?

First thing, get the ash issue out of your mind. For survival purposes, you run the gasifier for several hours and the ash will just lay next to the nozzle. When you go to refill the gasifier, dump out the contents, remove what ash you find and put the charcoal back in. Easy! So try this. Take your 5 gallon bucket, cut a 3/4" hole in the bottom and line the bottom of the can with 1" thick layer of clay you dug from the ground. Leave the 3/4" hole open but surrounded by clay. Fill with engine grade charcoal and set the can on three bricks so it is elevated off the ground. Take the lid and cut a 3/4" hole in it. Apply some silicone chaulking to the bottom of a 1" flange fitting and bolt it to the lid. Insert a 1" pipe nipple into the flange and place a 1 1/4" sump pump hose over the nipple. This hose runs to your engine where you have it adapted to the carb. Start the engine on gasoline and while it is running (and sucking air through the gasifier) light the charcoal from the hole in the bottom of the can. As the engine draws air through this hole, you are making chargas which will start to cut out your engine. Here is a little dance of running too rich on chargas and gasoline so you will have to slowly cut back on gasoline while adjusting the air. Anyway, it is easily done once you know what you are doing. No fan needed. An easier way is to use a hand crank fan and thereby eliminate the need for gasoline.

As far as cooking food, use a TLUD stove, not the gasifier that is designed for running engines.

Got to fire up my Gravely and mow some grass now. Can I call that MOC? (Mow On Charcoal)?

Gary in PA

As always. Excellent GaryG.

TomH a we-all-fell-down gasifer air pump can be made from the white or black plastic piping.

Use 4 inch for the body. About 24 inches long. Mke it double action pumping pushing and pulling.

one end cap hole drilled for an all-thread rod. Piston two wooden discs sandwiching hat wool felting in between. Nutted to the all thread. All thred rod trough the end cap shethed with smooth any-source metal tubing. End caps air inlet valves made of rubber tire inner tubing. End caps outlets those those pipe treaded plastic ends. Plain hole inserted. J-B or other two part epoxy welded.

Need outlet one way flapper valves too. Or simple snorkel floating balls valves.

Can starting up suck (leave the rod end cap UNglued for disassembly removal tars cleaning) or blow as you wish hand plunger pumped for engine fueling systems.

As GaryG said once running your engine is your air pump.

Cooking is better done natural draft dedicated cooker system. Many out there.

Ha! So. We-All-Fall-Down, Preparing it is to pre -stock hole saws, hack saws, files and drill bits and long storage actual brand J.B. weld or other actual metal tube and metal can dispensed products.

AND then using these to know how too.

Make plastics lawn furniture. Kids play tool-toys. They will love balls and inflatables pumping up. Just DO something. Real. Today.

And I am not meaning you TomH. saying this. You are DOer. The folks you are trying to bring along. Too late later. When everyone else is out “sourcing” at the same time.

Stay at home to stay safe. Protect what you got.

Wandering around you can only be viewed as a refugee; or a raider. Being accepted as a Trader evolves later.

S.U.

![]()

![]()

![]()

My attitude too. At least in the beginning. But then, somewhere, I heard the term ‘analysis paralysis’, and realized that at some point you just have to build something.

Rindert

I mentioned mattress pump yesterday to Tom , but forgot to tell him that the batterys have a limited life , unless of course the newer ones are now using li ion cells , mine had a lead acid and wore out pretty fast so rewired the plug to accept power from a spare battery while running .

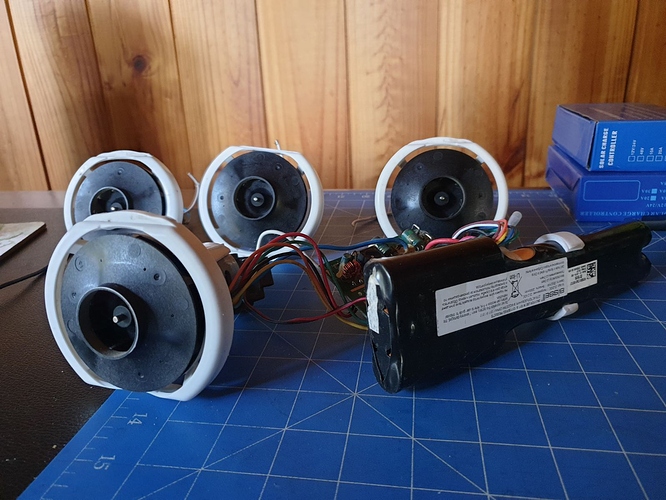

after a while , not sure how many months i noticed that it was squealing a lot i guess the soot and the moisture had got to the bearings in it , and was just about to go buy a new one when a friend asked me if i needed any li ion 18650 cells if u do i have a few packs from a job i am doing stripping down faulty brand new hand held vacs .

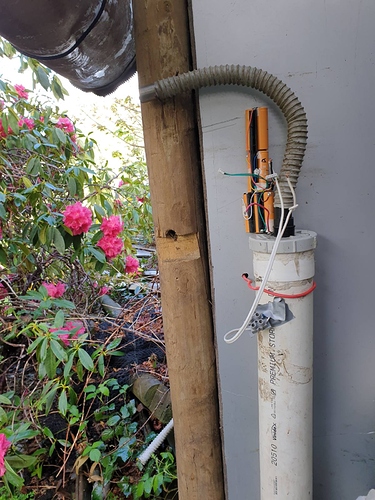

I was round his place like a shot and he was surprised that i showed as much interest in the pile of motors rather than the large large pile of 7s battery packs , anyway not being greedy i grabbed half a dozen of each , now i have a life times worth of blower /suckers the fan housing were 90mm that slid into some old 90mm pvc pipe nice and tight glued into place with a end cap with a 25mm pipe barb to allow suction in and then on the bottom another end cap and on the bottom a bend withanother 25mm pipe barb and then i tied it to the wall of the shelter where my engines are , now when i start the charcoal up i just break the fuel line from the air mixer and and plug into the top pipe barb for a variable suction speed thanks to the balancing leads on the 7 cell battery as each pin is a different voltage .

So dont throw away them old hand held vacuum cleaners there’s a whole new life waiting for them . few pics just to show u what i mean, i should have used new pipe and clear silicon and connectors for the battery to make it look nice and posh but i was in too much of a hurry to try it out , will do that at a later date .

You guys are my kind of people. You have no idea of how sick I am of hearing people blah, blah with all kinds of future plans but never actually do anything.

Steve. I mentioned before that at one time I had a lot of expensive tools accumulated over a life time and watched them all become a large pile of junk in about an hour. I couldn’t think of replacing most of it now but don’t really need to. Everything I have shared here was made with a Harbor Freight angle grinder and cutting disks. A set of 12 V Milwaukee tools one of my sons gave me and a Stick welder I got off Amazon for about two hundred bucks. My Lincoln Mig welder quit working last winter and I decided that I wasn’t going to buy Argon anymore because I couldn’t supply it myself or the other consumables , but I can stock many pounds of welding rod. Also this welder is an Inverter and weighs about ten pounds and will run 1/8 7018 on 120 off my inverter generator that weighs about twenty five pounds. I can just carry one in each hand and I’m good to go do anything. Of course all these projects would be much easier using Mig or TIG, but they are do-able with much more basic tools. No reason for anyone to think they can’t build something because the tools are too expensive. I’ve welded with car batteries before just because I saw it in a book and wanted to see it it would work. It worked barely. If you had a way to better control the current it would work better.

And your on Gary. I’m going to slap together just what you described. I liked how Koen used a burner to flare his gasifier in one of his videos. That’s what made me think about using it for cooking. Also I’d like to make an outside kitchen and do my canning out of the house. I was doing it with 80-90 per cent humidity this year.

Hey Tom, If you are interested in a TLUD stove that can work for an outdoor kitchen, check out this video https://www.youtube.com/watch?v=EuQvycVP7CA I’ve made some improvements to it over the years, but the principal is still the same. It is a batch system but you can add some wood toward the end to prolong the cooking. And in the end, you have engine grade charcoal.

Gary in PA

Is this the same stove you showed making hot water at post 132? I’d like to see more about how that worked. I mentioned that I made hot water to heat my floors with coils in my wood stove and it was along the same lines as yours, into the hot water storage and distribution. I didn’t understand how you got the coals out from under the angle iron frame in the photos. It appears to slide forward and back but not enough to clear the top barrel.

Aside from a harvest kitchen, I need to find a way to get a lot more heat into my greenhouse in the winter. In post 137 I showed a picture to the poured concrete tank I built in there for an aquaponic set-up. The far end of that picture and tank has a solid concrete roof. I’m thinking of a way to build something in that three foot by three foot space to heat the water in that tank and also give off radiant heat. I’m guessing the the outer barrel in your heater gets hot. I could partition off that area and remove the front section of wall to access air control valves. Getting up through the roof would not be a problem. How much radiant heat does this stove give off. The third picture in that post is the opposite side of that tank. There is the feed and barrel for a six inch Rocket Mass Heater there. When I build it I was concerned that the heat from the barrel would be a problem for the heavy clear tarp I have on the roof so I build that grow wall partition to solve that. It was not necessary. Even though the barrel will hit over 600 F it doesn’t really radiate that much heat. The concrete walls within a foot of the barrel don’t get much over 90F. In front of that wall is the heated bed. Three foot wide and about 15 inches high. It has thirty feet of 6 inch duct running through it that runs its length and back and then exists through a flue next to the barrel. Even with the barrel at say 600 F by the time the hot gas gets back to the flue bed has absorbed all the heat and exit time on the surface of the flue is in the 80-90 degree range. The surface of the bed will get around 80F but doesn’t really keep the greenhouse much above 50F in the dead of winter. We don’'t get much winter sun in this area. Maybe one day a week if we are lucky. Anyway the point of this long winded tale is I need a lot more heat and am looking for ways to get it.

I would be hard pressed to run a canner on your stove. I use an All-American canner. It’s thick, aluminum and takes a long while to get water up to a boil. A lot of stuff I can needs to be at 10-15 PSI for up to 45 minutes. Takes about an hour to get to pressure just on a propane burner, but I would like to bat around some ideas about heating that tank of water. There is another 150 gallon tank built into the floor I’d like to heat as well, but I’d have to use a pump for that whereas the tank could be totally thermosyphon.

Just a thought Tom , i understand how rocket mass heaters work and and are very efficient , but if you also need some radiant heat then have you thought of a standard wood burning heater with a back boiler in it ? my second fire upstairs has a 30 kw back boiler that feeds 8 radiators around the house , and the large open space room where the fire sits is so toasty warm ,

Dave

Could you describe your system a little Dave. What does the back boiler look like and how do you feed the water through the radiators.

My system is a standard slow combustion stove ,with a hydronic boiler fitted around 3 sides inside of the fire box , the water will start moving up towards the tank in my loft space as soon as there is a few degree’s difference in water temp ,thermo syphoning into the tank and back down into the fire , as soon as water reaches 40.c a pump then starts circulating the hot water around the house to the rads and back to the tank .

Dave

I would like to understand your system better Dave. You are heating how many gallons in the sides of your firebox? And that is creating enough expansion to feed the tank. Does the pump push the return water back to the boiler and then does that push unheated water up to the storage tank? In the system in my house the coils in the fire box draw from the bottom of the storage tank, which is open to air, heat the water and feed it back to top of the storage tank. The pump draws whatever is in the tank. The pump runs continuously. The temp control switch on your pump is a better plan. I just never put one in. Electricity is not real expensive in this area and the heating coils keep a pretty constant supply of water that is right around 140 to 150 F. Keeping the pump running keep the system from overheating.

Excuse my convoluted thinking. I’m trying to work this out in my pea brain as I go. Since the greenhouse is off-grid I want to avoid any need for a pump. I’m interested in your three sided boiler because I could bring water into it from the bottom of the tank and it would naturally rise in the boiler to a point level with the water in the tank. Then as it heated and expanded it would just dump back into the tank continuously. Then in addition to the water being heated in the firebox I like the feature in Gary’s Keystone stove of using a replaceable bucket to provide the heat and produce charcoal at the same time . I would rather not have to deal with swapping the bucket from the top. I’d rather build a sealed door in front to remove and replace the fuel supply. The main thing is to draw as many btu’s with as little loss as possible. My fire box in the house was built in when I built the house. The smoke path is out the back of the stove, right angle back to the front and that section of ducting , it you would call it that is as wide as the stove and three inches high. it is encased in six inches of concrete and then at the front it rises and then goes back to the rear to feed a sort of plenum and all that is again incased in concrete. From the plenum a six inch sch 40 flue runs 25 feet through the roof. The fire box always runs hot with additional lightly pressured air feeding the fire. After passing though the ducting and being absorbed by the concrete the flue seldom read much over 220 degrees F. the fact that I burn a fairly superheated fire keeps it from building much creosote. I have to clean it at the start of the season and usually once around the end of January. The point being that most of the heat, like in a Rocket Mass Heater, is used and not piped out into space. I’m looking for something similar here. If anyone can make sense of of this please feel free to chime in.

Hi Tom , the amount of water in the whole of my system is pretty small , i’m afraid it would be a wild guess but the Header tank up in the loft space is only 30 litre’s i think ,then coming out of the fire at the back are 1 inch copper pipes that do a 90 degree turn up to the roof to the tank , on these 2 pipes there must be NO restriction’s like pumps or valves by law nothing must impead the flow so that if there is a powercut thermo siphoning will carry on as normal so no build up of steam in the boiler to go boom .

then i guess in all the rest of the pipe work and radiators there would be around 40 litres .

the pump side of the system works via T’s on the flow and return pipes to the tank ,mine is a open system so its not pressurised so no danger of over heating and blowing apart

My system would be a typical wet back system for a house here in Australia or the Uk so not sure of the regs over there in the states .

I wish i was closer i have a woodchip heater well 2 infact sitting outside behind my shed , one i used to head a spa out in the garden , boy it worked so well and would be perfect on garrys keystone stove , i took one apart and its a copper tank that is hollow in the middle so the flames are drawn up the middle heating the whole area of the tank it even has a chimney formed in the copper tank with the in/out pipes brazed into the top ,

i used that on top of a open fire pit outside to heat my spa water up to 40deg c in 4 hours cant remember the volume of water in the spa but it was a fair amount , if no pump is involved you must make sure that you will have a level where water will flow back to the fire box so its all done by gravity and thermo siphone .

Dave

Just planning projects, so of course I have questions. I have a WK gasifier that I built but never used for anything. Par for my course. I’m thinking that this winter I might like to build a wood gas vehicle using it. I have a wrecked 1985 GMC Jimmy that one of my sons ran in to a tree and dumped off her about 20 years ago. It has a 4.3 liter six but I’m not sure if its carbureted or has a TBI. A tree fell on it at one point so I’d just take it down to the frame and build a pipe frame cage around it. I don’t know if anyone here watches the TV show, RoadKill Garage but these are absolutely my kind of people. Here is a link to a clip showing what I’m thinking about building out of the Jimmy. The Gasifier was never intended to go in a vehicle and only has an 8 inch fire tube. Not sure if it will be big enough to run that engine but I know a few guys here have built around that engine. Also wondering if anyone who isn’t running on an OBD1 or 2 ECM has tried the MSD adjustable timing module.

https://www.google.com/search?client=firefox-b-1-d&q=msd+adjustable+timing+control

Also, I never paid much attention to that engine for anything, but doing some research I find it’s just basically a small block Chevy with a couple of cylinders lopped off. I don’t know which size small block yet, but a lot of the parts are interchangeable between them. That would be pistons, rods and the whole valve train. It got me to thinking. I have always wanted to make an air compressor out of an functional in vehicle motor. I saw one done with an old VW engine on the web but no details. Been cutting and hauling firewood all day and I’m really tired and I’m using that as an excuse for what’s probably foggy thinking. The thinking part is what if you took the distributor from the V-6 and installed it in the V-8? That way it should just fire the three cylinders on each side. The firing order would dictate which cylinders you were just compressing air with. With a check valve fitted into the blocked off exhaust tube on some headers you should get a push of air with every forth stroke. Not sure about this but with an extra lobe machined on the cam for those two cylinders and a check valve in the spark plug hole you should get air every compression stroke as well. I’ve never had a custom cam machined so I’m guessing that would be a bite. If my thinking is all wrong here be sure and tell me. I can take it.

Tom,

Here is a flat head Ford engine/air compressor, like what you are imagining. I have seen the 302 ford v-8 set up the same way.

Sorry. Wrong thinking.

The camshaft lobes timing for your make-air cylinders would be far from good effective.

Those VW converted used a specially ground camshaft.

Also your V-6 distributor has the 6 cylinders spaced timing firing (distributing) at the wrong degrees for your V-8 spaced remaining 3-4 cylinders at TDC.

You’d just not wire stuff the V-8 distributor cap cap the cylinders you did not want spark to. And inside the cap grind off the brass/aluminum pins so’s not to arc carbons track.

You will end up with a low power shaking somewhat rough running engine pumping very oily air.

S.U.

I remember back in the early 80’s Cadillac had an engine that ran on either 8 , 6, or 4 cylinders, depending on power needs. I don’t remember that it worked well, but they sold quite a few of them. I’d just like to be able to produce a decent number of CFM without laying out the cash I did for my defunct compressors. Don’t care about oily air. It’s main use would be air tools and motors.

Well TomH. , there is a way to do it on a V-8.

Back in the 1960s both Pontiac and IHC took one of their base V-8’s and developed them into four cylinder engines. Using just one bank of cylinders.

I’ve never seen inside of either of these two engines.

“I think” they just used the same crank shaft and camshafts. The blocks were special to not have the one bank; its coolant and oil passages.

Ha! I have seen both engines in factory vehicles. Looked kinnda’ like a slant-four.

And then a few have converted inline sixes to inline three cylinders.

S.U.

Just an idea. I would cast up a special bell housing and rig two engines ass to ass with clutch still in place. Please pardon my french, I’m trying to be clear. The compressor’s cam timing would be changed to allow it to run backwards. This is sometimes done. I saw a Farmall M tractor built into ‘Hi-Cropper’, sort of a proto combine. Thinking, you might be able to weld fabricate a bell housing out of a large diameter pipe and two adapter plate type flanges. Second thought, delete the clutch and keep a valve open when starting.

Rindert