I have a miller welder sitting in my shed as well Steve. I think I bought it in 1985. It’s a Blue Star. only 10,000 watts but it is four pole. I have a four cylinder engine out of a 80’s honda civic. I was going to rebuild that and mount it to the miller head to run on wood gas when I built the gasifier. Things got in the way. The fire I mentioned took out all my mic’s and dial indicators and a hundred other things. I won’t be rebuilding engines anymore but I’ll eventually take the oil pan off this one and see what the lower end looks like. Should still be serviceable. I remember my grandfather packing babbit into the mains on old flatheads to get a couple of extra thousand miles out of them. I would have done better back then.

Thanks for the thousand words picture Tom. I see you figured out how to post pictures!

Thanks Gary that’s good info. That was the first burn I ever did with that rig. I thought about making the 5" opening at the top bigger. Logic was: it would be much easier to cut it if it was too small rather than add something if it were to big. And I was thinking about those 5 gallon tluds, estufa fincas, … I did a LOT of reading. Had to just DO something finally.

Btw have you ever done anything with condensing the volatiles, making methanol, or anything along those lines?

Gary G., I still use your single barrel burner with open-ended barrel afterburner on top to make charcoal. Is that still your preferred method?

OK. No one said anything about my flange question. This is my gasifier.

You can see it’s been sitting a while because there is moss growing in it. I had to cut these flanges of of a plate with a torch. That sucked. I’m really curious how other people do it. For the pre–heater tank and filter tank I just bent a piece of strap around the body of the container and set the top in it and packed it with refractory cement to seal it.

That is a pretty sweet gasifier. With those skills I might consider making a chunker and running a decent sized engine off it…

I will repost the question in case folks missed it. I haven’t built a WK.

Thanks Sean. You guys have inspired me. I’m going to start hacking up some fuel and learn how to run this thing. I build a lot of stuff. Some of it never gets used for anything because I’m an idiot. I’ll have to figure out a better grate shaker that runs on some kind of timer.

I don’t think you are an idiot. I think you -really- enjoyed building, it is THE challenge. Chunking wood not so much. I suspect after chunking a bit, you will start figuring out how to automate it, and maybe even come up with something better.

Sawmill slab leftovers like Wayne uses are really nice because they have been cut to a fairly uniform thickness already.

You can do an automated grate shaker. If you just want a simple constant timer one, you can do it with a 555 circuit, or you can use a microcontroller like esp8266, arduino, or microbit…or you can use a small computer like a raspberry pi. The latter two can be programmed using a blocks interface, which is like programming with lego’s. Microbit, use can use their website, and the pi, uses scratch3 from MIT. You can use the other two, a simple timer is literally the intro programming blinky light example. loop forever doing turn light on, wait, turn light off, wait. You have to adjust the times to something appropriate but that is it. Then you have the pin trigger on and off a relay which may flip a solenoid or run a motor. It is a lot easier then it sounds.

Jeez, I hope so because I’m not familiar with the language you speak. I was thinking of a windshield wiper motor on the lowest intermittent setting. Is there a ready made plug and play control module that a small 12V motor could be plugged into. That would be about my speed.

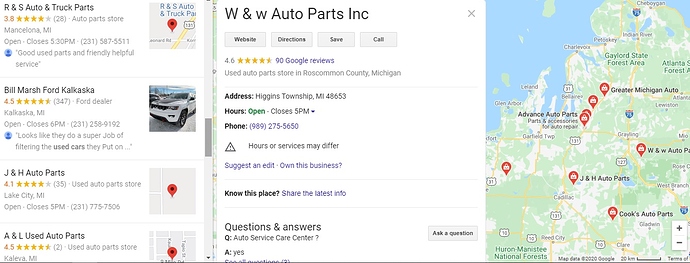

Thanks for thinking I’m not an idiot. My wife will strongly disagree. My biggest problem is that the area I live in has been taken over by people who wanted to get out of the crap hole urban war zones down state. They had the money and money talks, so now we live by their values. Little junk yards and scrap yards have been driven out of business. The big scrap yards can only take stuff in but can’t sell it for junk so getting old water heater tanks or well pressure tanks for instance is hard. Same with regular steel. You have to buy it new now, outside my budget. My personal scrap pile is about down to crumbs now. Getting harder for me to feed my addiction.

Make friends with the local plumber. Intercept the product before it hits the scrap yard.

Hey TomH.

That BenP’s book you said you have, has a simple rsettable relay timer system all layed out for it’s windshield gear-motor grate sifter system.

He does give all of the source part suppliers.

Flanges? Just don’t. Use V ring grooves with fiberglass stove rope seals.

3-4 pull-tight bolted tab clamps like BenP. shows.

Or barrel top V-band ring clamps like WayneK. uses.

Regards

Steve Unruh

I read that book cover to cover several times. I guess I wasn’t paying attention. Thanks. Flanges? We don’t need no stinking Flanges Man. Christopher Lloyd. Going south.

Speaking of going South, If you get away from the Champagne, Caviar and Golf that is Traverse City, and do some looking around in farm country (inland), you will still find some scrap yards, I think. You just need to get to know your local welding shops, fab shops, small manufacturers, Well drillers, HVAC and plumbers, as Tom W. suggested. You would not believe all of the scrap that emanates from Television stations these days, with the FCC channel re-pack changes. You would also not believe all the old steel office furniture and filing cabinets, equipment racks we have taken to scrap metal buyers. I have intercepted some of that, why I am grid-locked. You can have Too Much!!

You are probably right Mike. I live in Leelanau county. It is zoned so that they don’t even allow fast food restaurants. The last car recycler was closed down about 5 years ago. I imagine if I were to wander around Grand Traverse County I could find some stuff but I leave my property about once a month to go to Menard’s for supplies but I’d like to get grid locked again.

Hi Steve, Yes, the 55 gallon barrel with the big afterburner is still my preferred method. It is easy to load up a batch and takes about 20 minutes of total time from my day to load, tend and dump the char. If I start early I can get two burns in a day with the same barrel. It also makes a high temp char which is good for engine grade charcoal. The down side to this method is timing. You cannot forget about it or you lose charcoal.

Gary in PA

Gary,

Thanks for your reply. I remember in your videos that you mentioned you had tried different variations and had settled on that as being the best for you. I like learning from other people’s experiences, saves me from having my own. Of course, you never know when you might stumble on an improved method. Yours has worked very well for me. Thanks for your contribution to the art.

There used to be a reclaimed metal place in Traverse City. I think it was just south of the airport. they are probably more expensive then a junkyard though. I think there was one by Empire as well.

You could probably make a chunker for grapevines and then charge vineyards for removal or converting it to char.

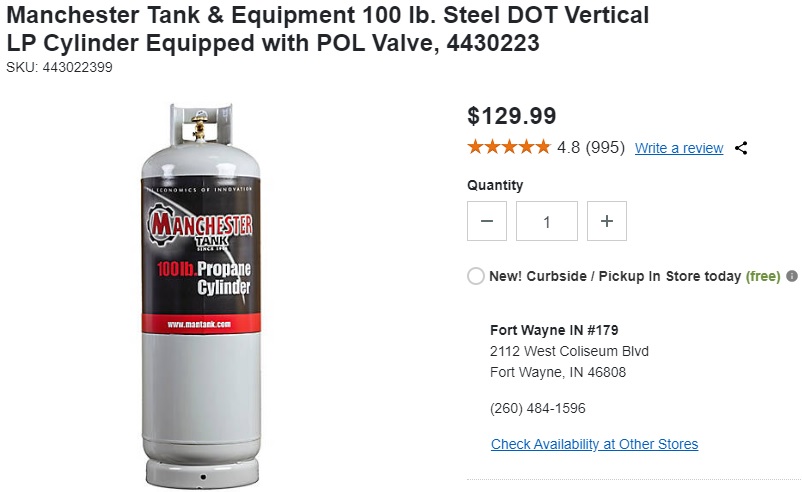

I Know the guy that owns R&S I built his house in 1997. Car parts are not a problem. I have Three junk trucks and a Ford Escape out on my back ten. They have to be camoed because you cannot have a vehicle that is not licensed on your property. If I wasn’t so old and so dug in I’d head for the UP. What I really need is a bunch of angle and plate. I do manage to scrounge up the occasional water heater tank. I built a lot of stuff out of a frame for a mobile home I came across years ago and out of 300 gallon fuel oil tanks when everybody was getting rid of them. I’m going to check with the nearest propane place about 100 pound tanks. I hear that some place cut them in half but will sell them. I have no idea what they are going to do with this economy. It was broke before the covid. Can’t see how they can revive it. If SS goes down the tubes or my stock market invested pension, I figure that if I could make simple charcoal gasifiers cheap enough I could make some kind of living at it. That’s why I want the propane tanks.