Hello Jakob, Chris gave you good advice, so I can only continue… If you are thinking about bending pipes, it is important to know what is the cross section of the pipe and what is the wall thickness, if you intend to bend pipes with a larger diameter and a small wall thickness (for example exhaust pipe) , the tool for this is quite demanding and expensive, because a hinged element is inserted into the pipe, which adapts to the diameter of the pipe, and on the outside, the bending tool hugs the pipe tightly … if you try to bend such a pipe with the hydraulic tool from Chris’s other link , it will deform, this tool is suitable for bending pipes with a thicker wall, seamless pipes are best bent. A tool for bending thin-walled pipes would also come in handy when making a gasifier, I will ask a local craftsman who manufactures and repairs exhaust systems for such a favor.

Ok I told the customer we are going to have to use schedule 40 . Chris that hydraulic bender do you think it would operate horizontal?

I have a little bit of experience with pipe bending. I’ve used it to make bicycle frames and little stuff.

Harbor Freight sells a roller bender that can do super long stuff, the first link that Chris shared. I got kind of burned by one of those because someone took the handle out of the box I purchased and they didn’t have a replacement. I just use a wrench.

That hydraulic pipe bender should be used in very gradual bends added together. It will kink even sch40 iron pipe.

For horizontal you can get one of these, I have one lag bolted to a stump. They’re all over eBay and Amazon, biggest I can do is 3/4" EMT conduit for frame of reference but it won’t kink tubing. I’ve used this to make complex curved exhaust for go kart engines.

I installed many miles of pipe handrail when I was doing Ironwork Jakob . Of course those were straight runs with turns to begin the next flight in the stairways of high rise buildings. We always used welded pipe fittings cutting them to get the radius we needed. If you can’t do it with a bender you could consider using these.

https://www.google.com/search?client=firefox-b-1-d&q=Sch+40+elbows+for+hand+rail+fabrication

These guys are saying 1 1/4 for ADA compliance. But I don’t know what the ADA specifies.

The one I saw put in was like 4" stainless, and it was prefabbed except 1-2 welds they had to do onsite because of the length.

Hi Jacob, just some ideas from me, if this handrail is going to be made from fairly thick walled steel, crimp / bending is one way.

First make a handrail out of for example copper tubing, as a pattern/ model, then you could work with the steel on the ground.

This is based on heating “dots” along the inner radius, the most important thing is: it must be heated fast! (In seconds) to orange/yellow heat, when cooling down: as soon the dot passed “brown-ish” heat, cool it with water.

The principle is: the fast heating, the expanded metal has no place to go, and therefore the dots became thicker, and blah, blah (im pretty sure you understand this)

It’s like old-school car body work/repair.

It’s the FAST heat-up that is important, therefore a pretty big oxy/acetylene torch is needed, or better: a big induction heater (atleast 7,5 kw)

Well, it is time consuming, wet, needs a lot of oxy/acetylene, but gives impressive results.

And i have seen your works, and you would have no trouble with this process ![]()

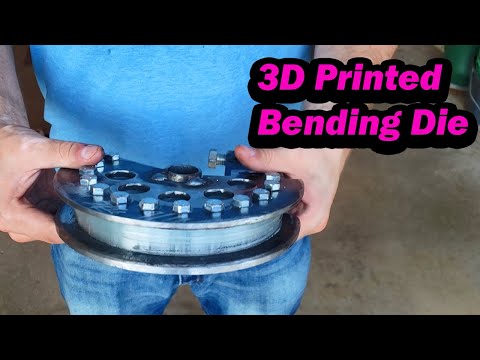

I have seen a few videos out there of people 3D printing custom dies (of whatever size you want) to bent square and round stock .

Mainly for go cart frames if i remember right.

Will deffinately not work for heavy wall tubing.

They printed with 100% infill (not sure what filament) then sandwiched the plastic between two steel plates.

I have not tried it. But found it interesting.

Example;

Wow! There IS a mathematical formula out there for determining the curvature of a handrail. But you don’t have a consistent curve so that’s not going to help.

Perhaps make a physical model in place? Perhaps get all the brackets in place temporarily, with mounting tape, and then bend a piece of 10 ga wire to fit. Then use the wire as a guide to bend the pipe. Another material, such as cardboard, might also be used, but difficult for me to imagine.

Rindert

So the posts are set in concrete and I am mostly following a block wall underneath. My idea is to attach one end and follow it around with the bender I’m going to go get a harbor freight one tonight and see how it goes.

Keep us posted and take a few pics of the process.

In my head im seeing some sort of jig to hold the bender horizontally so you can roll it back and forth along the walkway, increasing the bend to the desired radius.

What length stock are you working with? 10, 24’?

How about using pvc pipe for pattern, if you heat it you can pretty bend it any way you want. I usually use a propane weed eater torch but have seen videos of engine exhaust, space heaters and heat guns. There is a learning curve if youwant it to look its best but for a pattern i would say somebody with your skill set could do it. You can allways reuse pattern for something else afterwards.

So I bought the 12 ton Bender from harbor freight and I spent 1/2 a day bending pipe. It works ok just set it on the ground and bend a little check it and do it again. I forgot to take pictures of what I have done. On the first day I guess I moved wrong and twisted a vertebrae in my lower back. I have been bed ridden the rest of the week. Yesterday was brutal and I went to the chiropractor and it is much better this morning but not great still. So I will post pictures when I get back to work.

@ccweb1 I am using 21’ schedule 40.

Rest up, and don’t stress your back out. Don’t be in a rush just on our account. I’ll be praying for a solid recovery.

I pray Jakob, that The Yehovah Almighty God the Farther will heal you in and by His Word the Messiah the Son Yeshua’s Name. So you can get back to doing the work that God has for you to do. You are blessed because you do believe in him who God sent.

jakob, how are you with your back?

the pain often comes from a inflammation what comes from wrong lifting weights…keep your back straight when lifting and bend your knees instead of your back…avoid too heavy lifting…i can tell you from own experience…when there is a inflammation go there with really cold water from the water hose for some minutes, and then keep warm your body…this often during the day done, and inflammations are going back.

anti - pain medicine is not so good, because you feel no pain more, work again and make it worse.

Im doin

g a lot better. I was in bed through Monday and yesterday Dad and I did some logging. To day I’m heading out to do the handrail again. Still sore but serious pain is gone.

Dad and Jesse came and worked for a day this is what we ended up with some more grinding and painting to do but the customer was very happy.

Sorry about the bad pictures light was terrible and my phone doesn’t have a good camera.

Most important part! Those rails look awesome.

Big job! Welded in place or prefab?