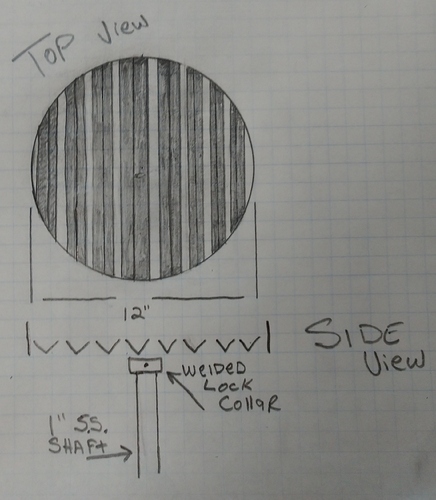

So after a long while I actually drew something up.

Drawing shows 1x1 stainless angle laying crotch up to cradle the ash for retention and insulation. The gap between each side of angle can be adjusted before welding them in, if you have a suggestion to the gap clearance I’ll like to know. Otherwise I was thinking a gap of about 1/8th inch. The end of each angle will be joined to the outer wall of the grate.

Max is going to ask for calculations for gas flow requirements but I think 1/8 inch is too close together. Depending on flow requirements - I think 3/8ths to 1/2 inch is better.

I’ll do my best to figure some of that out. Due to my idea of interchangeable guts, I’ll include a few flow expectations from multiple choke, nozzle, and hearth sizes when I can. I can’t say what engine I’m planning to run since I have a large collection of just about everything. From single cylinder Wisconsin’s to big block chryslers. I would love to build this to supply a distribution manifold that runs multiple antique engines at local engine shows. Polish it up and run it on display.

I hate to burst your bubble on running multiple engines on a single gasifier unit.

That is thinking like multiple engines being fueled from a single delivery tank like a propane tank.

Or multiple engines being fuel supplied from a single tank of gasoline or diesel fuel.

A wood gasifier is just like a gasoline suction carburetor.

To get proper fuel to air you are dependent on matching the suction/flow demand to the producing system.

It is actually very difficult to suction draw into an engine; AND pressure supply to a flare burner simultaneously.

Hint. You need a driven suction blower for the flare burner.

So. . . .to do this you will need a large capacity variable speed/flow suction blower to the gasifier able to suck that gasifier; AND pressure sully to your engines.

Can be done. Complex mechanical. Just like a mechanical gasoline fuel injection system is bugger-do to design and set up.

Team up with one of the electronics control folks like Matt Ryder for this side of it.

Will be a whole project in and of itself.

So much easier to match up your engine pulling a single matched capacity gasifier.

Everything then under slight negative pressure and CO leaking safe.

Until engine shut down. Residual gasifier heat then driving into slight positive pressure.

Regards

Steve Unruh

Thanks much for the heads up. For now I’ll pick and stick with one of my engines now. Getting ahead of myself with all that so I’ll go with the old saying of “get it operational before modification” haha

I’ll get flow numbers after I pick my favorite engine soon. Thanks again for the advice!

just wanted to show roots blower

Hi, Kyle!

26.10.2020

Just as Don sayed!

Too crowded grate bars will block the ashflow.

A vertical spindel for height adjustment is always handy.

But, what constructors have found out: A horizontal grate is a tremedous “heatlooser”, as it has an unprotected “view” staight downward to a “distant” ashpot.

A flat surface with “smooth ribbon” (for heat movement) and a good heatinsulation underneath will preserve more process heat further away from the restriction.

This prolongs the useful reduction process, otherwise killed off by unnessesary heat loss by radiation.

The white-glowing char radially just outside the fuel-pillar weight through the restriction can more freely be blown into new positions and thereby fill up cavities formed by “charconsumption”.

The ash will be blown off horizontally through a vertically oriented row of angle iron bits welded to a flat band around the oxidation cylinder surface.

This is easier to handle than the flat horizontal ring I proposed earlier.

The internal (volume) passages are still calculated as a percentage of the motors maximum gas consumption per second.

Max

Wow MaxG.

You just explained well the advantages to your bird-cage style of vertical grate can.

Certainly an eye opener to me.

Thanks. Good days are learning something new.

Regards

Steve Unruh

Hi, Don!

26.10.2020

Keeps warm over coffee-breaks? But needs daily ashing?

Max

works best with full ash bin.

Hi, Don!

26.10.2020

Sure, big volume , low intencity , “cooling-surface” relatively big; it needs still bigger insulation…

Max

HI, Kyle!

2.11.2020

To see the gas “appetit” of a motor:

Net gas consumption of a motor at WOT and a certain RPM:

V = Liter

n = RPM

4-cycle factor = 0,5

Half volume = 0,5 (snuffing 0,48)

Filling factor = 0,72

Reduction minute / second = 1/ 60

V x n x 0,5 x 0,5 x 0,72

================== =

60

This gives liter per second net gas consumption at WOT at the planned working or max RPM.

Max

HI, Kyle!

9.11. 2020

Hearth geometry with volume. Between nozzle-tips and restriction.

Separately you can calculate lower silo formation…

without affecting the gasification process proper.

Max

Welp. After the Monster Garage thing is over. I put hours into my personal build and fired it up last night. Each one I build and fired up for the first time never gets old. Same excitement and anticipation! Time to finish the Gasifier then start building the cooling rack and filter housing.

Nice looking fire you got going on there Kyle

Kyle, good to see progress. We need more photos and videos. Looking forward to seeing your influence on Monster Garage. Merry Christmas.

Made a skid, aluminum cooling rack with condensation tank, and other odds and ends. Glad I can get back to my own stuff after the show.

Thanks for the picture Kyle .

You may need to find a lemon or two