Still waiting on the last few bits. Also still haven’t made my plenum for the GMC yet. I will be making a second one for my generator.

Im looking forward to seeing your plenum for the GMC. I hope you post some pics. Are you going to have one or two air valves.

I have two, but only one does mixing. The other is either open or close.

For the air mixer it’ll just be a single one. The Finkbeiner style mixer has some odd ratios. Let’s say my throttle is 3", then my gas line is 2" and fresh air is 1.5" just judging from the picture from the Gengas book. Right before the throttle in the 3" pipe is a Venturi necked down to 2".

My plenum will be pretty simple just some 2x6 rectangular tube. I need to decide if I’m going to attempt to squeeze the Quadrajet on there or if a Dualjet would make more room.

Ron Lemler had a similar plenum for his Ford before going back to through the carb gas routing.

Oh if only I had a Double 4bbl Intake for this 350…

Okay so I have my momentary and LED now. I have it wired as such according to the Constants in the code:

O2= A4

Manual dial=A3

LED=D2

Momentary Switch=A2

Still not working. Everything is sharing a ground at 5v. Am I lacking resistors or is my wiring incorrect? Should I revert the wiring to how you originally had it?

The LED randomly comes on and cuts off, the Pots do nothing.

Did you mean a Momentary button or a Momentary Latching button? I have both since you mentioned Angel Eye switches.

Edit: I moved Servo to D6 and it now moves. Still figuring out how to get it in and out of Auto mode. Probably a short circuit between the chair and the dial. It will temporarily go into Manual Mode and then take over again in Auto.

Edit 2: Also I confirmed with my multimeter that I have both of my testing pots wired the same polarity, and both are climbing and dropping in voltage in the same directions but the Manual rotates the servo Counter Clockwise when the Pot is rotated Clockwise, the Auto Mode rotates the servo the same direction the dial is moved.

The manual switch is momentary. So it does not latch. You may need to install a 10k pull down resistor on the momentary switch input. If you power it on or reset the controller it should be manual mode and never switch into auto mode unless you push that button. If its switching on its own then there is noise its reading. So you will need to resistor to pull it down to 0 volts and eliminate the noise.

Yeah reading your edit. Thats exactly whats happening. If you jump a wire from ground to that pin it will quit this behavor and confirn you need the resistor. But what you discribed is exactly the behaver it has without that resistor.

When you turn the pot counter clockwise this should close the vavle. Full clockwise the valve should be wide open. If you have flipped the polarity you also need to reset the servo relationship to the valve.

yeah D6 is correct for the servo sig wire.

Few pics of you mockup or maybe a short video whould be cool!

Now you have the perspective of what this development looked like. Exept you are seeing this about 4 years in. Figuring out all these little quirks and things like that switch pin noise about made me rip my hair out.

Sometimes folks think microcontrollers are easy. It’s just ones and zeros, right? Once the code is working, you’re golden, right? Ummm, no ![]()

Pull down resistors, or maybe pull up. Noise on the digital lines. Power supply ripple. What, you forgot to initialize all the registers? Everybody knows you have to do that, right?

It’s a digital project, but it’s an analog world. Woe to him who forgets. He will be reminded ![]()

Yeah I also had the switch wired wrong. Had it wired to the correct spot on the board but I had the other leg to ground. I moved it to the 5v spot to share positive, and put the pull-down resistor from the button’s spot to Ground and that fixed the issue.

Without the resistor I just had to barely touch the button and it set off.

Forgot to take a picture but I’ve printed the valve adapter for the servo. It uses the two armed attachment that comes with the servos. It’s a very tight fit, you shouldn’t need glue. I’ll edit this message with a photo when I get home from work. Now I just need to make a printable box to be able to mount the servo to a conduit valve.

The conduit tube I’m using has a 1-5/8" bore and my idea is to find some U bolts that fit just right around the OD, that go through a printed or wooden “saddle” for the servo motor to lock it in place. I’ll need to finish making the valve first.

Edit: here’s what that adapter looks like

Under the hood, you can put that mixer valve anywhere. Dont install 3D printed parts on vehical engines. Place that valve in a cooler spot and hose it to the engine.

Yeah nah I’m putting it over near the fender, also any printed parts going under the hood are going to be PA6CF Nylon. PA6 is also very tolerant of moisture so it won’t weaken by too much. That said I think any PLA+ or PLA Pro should be fine over in the fender area where the engine fan moves some current around.

Well crud, accidentally ordered the 270° throw Waterproof Servo instead of the 180° throw.

Matt your code should be fine figuring that into the normal 90° throw right, since it’s specified in points? I remember seeing in the code it gives a range figure. Shouldn’t matter how many degrees the Servo can potentially do?

I don’t think it matters. I think it is done in degrees. It doesn’t matter what the servo can actually do. If not, we can figure it out.

This is the basics:

https://docs.arduino.cc/learn/electronics/servo-motors/

I got a couple of Unos to use on the bench and be a little more plug and play. I’ll wire one up and see if it does fine.

You can map it to what ever you want.

/*

Controlling a servo position using a potentiometer (variable resistor)

by Michal Rinott http://people.interaction-ivrea.it/m.rinott

modified on 8 Nov 2013

by Scott Fitzgerald

http://www.arduino.cc/en/Tutorial/Knob

*/

#include <Servo.h>

Servo myservo; // create servo object to control a servo

int potpin = A0; // analog pin used to connect the potentiometer

int val; // variable to read the value from the analog pin

void setup() {

myservo.attach(9); // attaches the servo on pin 9 to the servo object

}

void loop() {

val = analogRead(potpin); // reads the value of the potentiometer (value between 0 and 1023)

val = map(val, 0, 1023, 0, 180); // scale it for use with the servo (value between 0 and 180)

myservo.write(val); // sets the servo position according to the scaled value

delay(15); // waits for the servo to get there

}

If you just map that servo 0-180 it just opperate in that range. Its actually better that is the larger spread anyways as it wont ever be maxed out of travel and burn up if the controls overdrive the range.

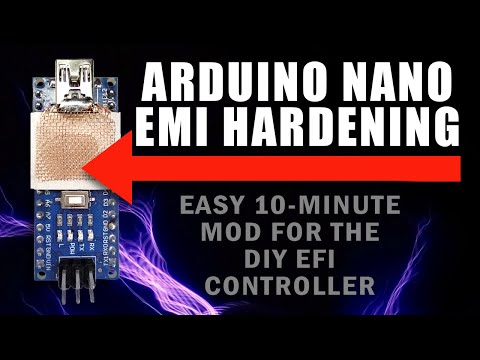

What do you guys think about this video? He suggests removing the voltage regulator, since you’d already be using a 5v regulated input.

If you are using a regulated 5v power supply with ground it isn’t a bad idea but you can wrap the whole case in copper or metal and use the vehicle ground, and put the power supply, in as well but shielded from the microcontroller. You can probably get some super thin shielding metal from like a computer case.